Module 7:

How to Develop A

Farm Food Safety Plan

Learning Objectives

• Name the essential parts of a Farm Food Safety Plan

• Describe why one qualified person should be

designated as the person responsible for the Farm

Food Safety Plan on every farm

• Conduct a risk assessment of the farm’s practices

and environment

• Describe management steps and practices

to reduce risks

• List key steps involved in developing a traceability

system including establishing lots and clean breaks

• Identify resources available to assist in developing

a Farm Food Safety Plan

4

Farm Food Safety Plans

• The FSMA Produce Safety Rule does NOT require a

written Farm Food Safety Plan

• However, writing a Farm Food Safety Plan was

identified by PSA Working Committees as a critical

component to implementing produce safety

practices effectively

• This module will outline considerations when writing

a Farm Food Safety Plan by incorporating both GAPs

and FSMA Produce Safety Rule requirements

5

Reasons for a Farm Food Safety Plan

1. Gets you organized and focused on food safety

• Describes risks you have identified and actions to

address those risks

• Defines your practices, policies, and SOPs

• Efficient and effective use of your time and resources

by prioritizing most important risk reduction steps

2. Best way to be prepared!

• Buyer questions/requirements

• Third party audits

• Food safety regulations

Food Safety Plan

▪Policies: What to do

▪Procedures: How

▪Records: Proof of what

and when

7

YOU Can Identify and Reduce Risks!

• Each farm is unique

– Practices to reduce risks

will be specific to your farm

– Best done by someone who knows

the farm and how it operates

• Each commodity is different

– Grows on the ground or in trees

– Harvest by hand or by machine

– Single vs. multiple harvests

8

Who Is YOUR Food Safety Person?

• Each farm should have one person to lead

the development of the Farm Food Safety Plan

– Will be supported by others on the farm

– May need a back-up in case the person is unavailable

• Should have food safety training and experience

to know how to assess risks and develop a plan

• Should have the authority to make necessary changes and

invest in resources to reduce risks

• Must make sure the plan is implemented

• Should be willing to be the farm food safety contact

§

9

Knowledge Is Your Friend!

• Writing a plan can be difficult –

begin with information you know

– Start with your general farm

information and what you do

• Some basic food safety knowledge is key!

– Assessing risks requires understanding risks and this

requires knowledge and information

– For many growers, preparing a detailed, written Farm

Food Safety Plan may be a new practice

• There are many resources available to help

10

Farm Food Safety Plan Parts

• Farm name and address

• Farm description

– Commodities grown, farm size, etc.

• Name and contact information for

farm food safety manager

• Risk assessment of practices and environmental

conditions on your farm that impact food safety

• Practices to reduce food safety risks

• Records that document practices

§

11

• Farm maps

• Farm policies

• SOPs

• Training records

• Agricultural water test results

• Emergency contact information

• Supplier and buyer information

• Traceability and recall plans

• Contact info for contracted services

Other Items to Include In Your

Farm Food Safety Plan

§

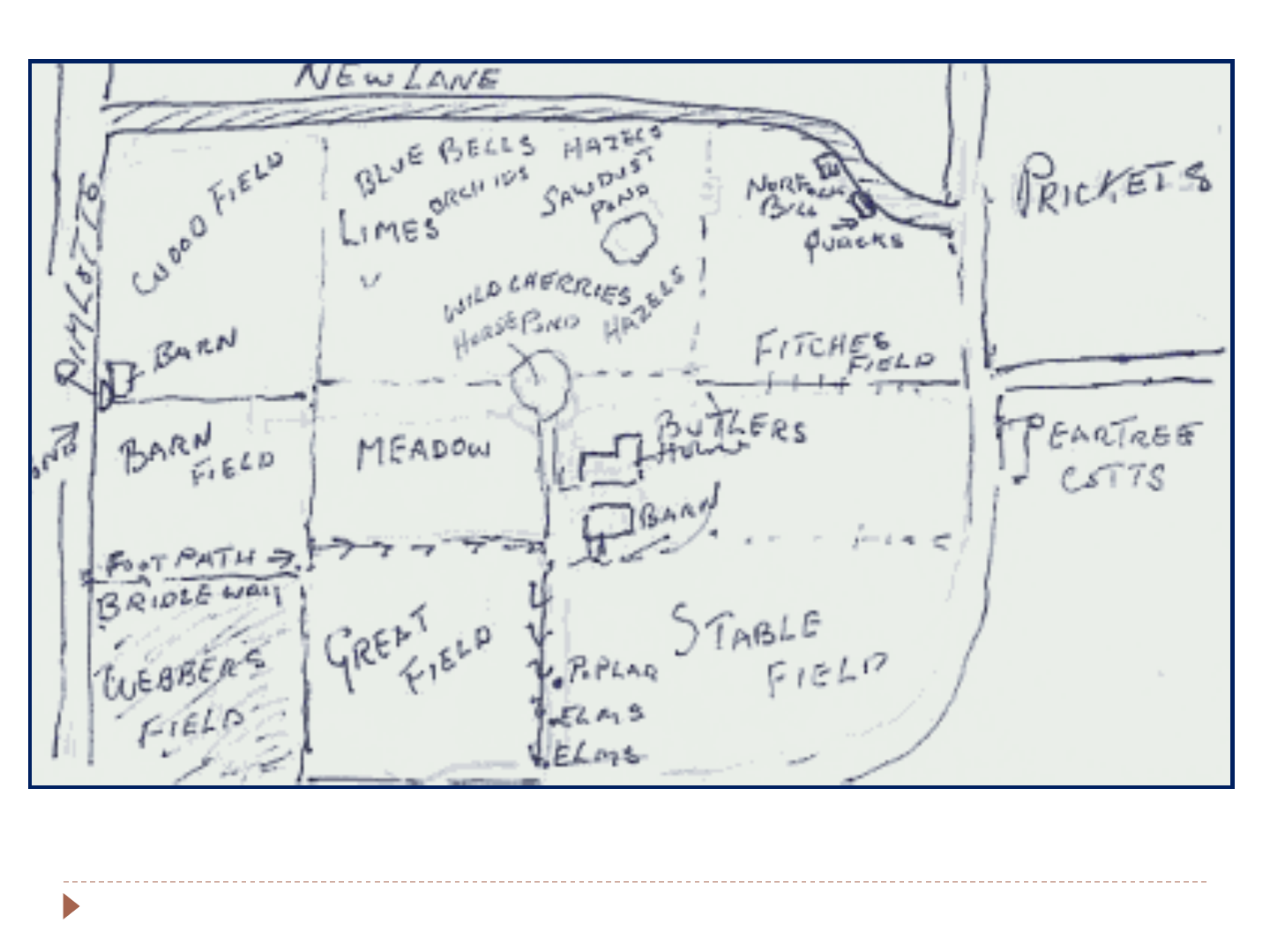

Farm Mapping

Main farm site and one for each non-contiguous field site

Be sure to locate and identify on the map:

• production areas (labeled according to traceback scheme)

• field packing, and staging areas

• field sanitation units

• active wells

• surface water sources

• regular or recent flooding areas

• manure or compost or chemical fertilizer storage sites

• septic systems

• any important residential/commercial/

other facilities adjacent to farm, such as sewage treatment

sites, landfills, dairy or animal farms, etc.

13

15

Step 1: Assessing Risks

• Identify risks that are most likely to occur, noting the

ones that could happen often

– Because time and money are limited, prioritize which risks

to address first

• Review all farm operations to

identify practices that contribute

to or increase produce safety risks

• Review the farm environment and adjacent land

• Focus on microbial, chemical, and physical risks

16

Ranking Your Risks

• Risks that can lead to whole crop contamination

• Risks that have caused previous outbreaks

– e.g., Contamination from postharvest water, wildlife fecal

contamination

• New or modified farm production practices that may

increase risks

– e.g., Hiring new people, changing processes, retrofitting

equipment, changing suppliers

17

Step 2: Develop Practices to

Reduce Risks

• Develop practices that will reduce identified risks

– Use resources and ask for help if you are not sure!

• Know what resources are required to successfully

implement practices

– Human resources (time and/or people)

– Equipment or infrastructure (may require changes/upgrades)

– Disposables (hand soap, paper towels, etc.)

• Create a list of tasks/steps that need to be done

• Designate a person(s) to be in charge of each task

Risk Assessment

Map out your process

Field

Production

Harvest Packing Storage

Adjacent Land

Irrigation water –

source and type

Animals

Soil inputs

People

Animals

Equipment –

cleaning

sanitation

Containers

Workers

Equipment

Facility

Pests

Water

Packaging

Temperature

Facility

Sanitation

Worker

Other

products?

Adapted from presentation by Jim

Gormy 3/2014 workshop: ”Local

Grower Food Safety”

Risk Assessment: Lay out a plan

▪ Questions to ask:

⚫ Are there potential sources of pathogens?

⚫ Could they get on or in your fruits or

vegetables?

⚫ What can you do to help manage or prevent

these risks?

▪ Good risk assessment leads to

good risk management!

Adapted from presentation by Jim Gormy 3/2014 workshop:

”Local Grower Food Safety”

Risk Assessment:

What should you be considering?

▪ Risk/Hazard

▪ Type of Contamination (e.g. bacteria type)

▪ Significance – Is it high or low?

▪ Risk Management Practices – what are you

going to do to minimize risk

▪ How are you going to measure the practice and

how often?

▪ Verify and record

▪ Anything new? Field? Commodity? Equipment?

Adapted from presentation by Jim Gormy 3/2014 workshop: ”Local Grower Food Safety

Risk Management Scheme:

Soil amendment Use

Risk/Hazard: Compost Use

Contamination: E. coli 0157:H7, Salmonella

Significance: High

Practice: 1) Purchase from vendors with

validated process

2) Validate own process if on-farm

(turns, temperature etc.)

3) Storage so no recontamination

What needed? 1) Certificate of Analysis each lot and log

2a) Temperature/Time over process and log

2b) Pathogen testing and log

3) Inspect piles and log

Adapted from presentation by

Jim Gormy 3/2014 workshop:

”Local Grower Food Safety

Risk Management Scheme:

Domestic Animals

Risk/Hazard:

Contamination:

Significance:

Practice:

What needed?

Domestic animals

E.Coli 0157:H7, Salmonella

High

1) Fences

2) Location down from produce

3) Ditch to prevent run off

4) Buffer zones

5) Do they have to be there

Visual inspection – weekly and log

Testing when needed

Risk Management Scheme:

Workers and Hygiene

Risk/Hazard:

Contamination:

Significance:

Practice:

What needed?

Restroom

Cross-contamination with E.Coli

0157:H7, Salmonella, viruses

High

1) Worker Training

2) Sanitation procedures

3) Location

4) Paper towels/toilet paper

5) Soap, water

Visual inspection – daily, 3 times a

day, logs

Adapted from presentation by Jim Gormy 3/2014 workshop: ”Local Grower Food

Safety

25

Step 3: Document and Revise

• Write a plan to guide implementation of practices

• SOPs and policies will outline what needs to be done

for those who are responsible for completing the task

• Build recordkeeping into the logical flow of activities

• Revise your plan if it is not working or when practices

change

• Review and update your plan at least annually, or

whenever practices, personnel, or equipment changes

26

Educational Resources

• There are many educational resources available to

help you write a Farm Food Safety Plan

• Resources are available through:

– Land grant institutions and extension programs

– Industry or commodity specific guidance

– Produce trade associations

– Federal guidance

– Independent organizations

• A list of educational resources are provided in your

training materials

27

Food Safety Plan Writing Resources:

Be sure to make them your own!

• There are many available resources, including

templates – pick which one works best for you

• Tailor templates to meet YOUR needs

• Template plans, recordkeeping logs, and SOPs give

you someplace to start and are easier than building

the plan from scratch

• Be sure to make it your own, so you know what is

in the plan and that it will work for you

28

A Few Thoughts About Your Plan…

• Only include practices you are doing on YOUR farm

• Do NOT include things you wish you were doing

• Does not need to be long or complicated

• Pick practices and schedules you know you can do

• Focus on risk reduction!

Food Safety Plan

▪ Your grower information

⚫ Who are you?

⚫ Crops you grown, and site location

⚫ Person(s) responsible at your farm

⚫ Water source for your farm

⚫ Type of soil

amendments/handling/storage that you

use

⚫ Facilities available for your operation

Food Safety Plan

▪ What are you going to do? What is

your policy?

▪ How are you going to do it?

⚫ Analysis

⚫ Training

⚫ Treatments

▪ How often are you going to do it?

▪ What records are you keeping?

34

You have written your plan, your

practices are in place, records

are being kept, and delicious,

high quality, safe produce is

being grown and packed.

So now what?

TRACEABILITY

Final Steps

Farm

Buyer

Consumer

PRODUCT IDENTIFICATION

Traceability

Who am I?

Where do I belong?

Where have I been?

Where have I gone?

Traceability: ability to follow movement of food through

production, processing and distribution

Traceback

▪ Ability to track food through the food system

back to their source and forward to the next

destination

▪ DOES NOT prevent a foodborne outbreak

▪ CAN quickly identify the source of a product

and speed an investigation

▪ CAN limit damage to the consumer

▪ CAN prevent damage to the innocent grower

Penn State Extension 2012

37

The Value of Traceability

• Following quality

– Identifying boxes that have quality issues

• Keeping track of amount sold

– Knowing what sold well and how much money you should

be making

• Minimizing foodborne illness impacts

– Recalling a contaminated load/lot/bin

– Knowing how much was sold and in the marketplace

– Knowing who may have purchased/consumed it

38

Product Tracing:

One Step Forward, One Step Back

• Traceability means identifying where the produce

came from including inputs (one step back) and

where it went (one step forward)

• For growers, this means knowing the field where it

was grown (step back) and the buyer (step forward)

• This does not mean you are

responsible for the entire system,

especially if there are multiple

steps to the consumer

40

Understanding a “Lot”

• Product tracing requires defining and following a

distinct portion of the crop. This is called a lot.

• A lot is a distinct and limited portion of a crop

– e.g., all of the same commodity harvested on the same day

from the same field

– It may require establishing a ‘clean break’

• Difficult issue: How big should the lot be?

– If there is a problem, the whole lot

will be recalled, so the bigger the lot,

the bigger the recall

41

Developing a Lot Code

• Can be numbers or letters, or a combination of both

(alpha-numeric)

• Should identify specific details about the lot

– Farm, field of origin, harvest date, and more

• Should be unique to a specific lot

• Should follow the lot

– Attached with a label, stamp, or sticker

to the sellable container (such as a box)

42

Steps to Developing a Lot Code

• To begin developing a lot code, growers should

identify:

– Field locations

– Commodities and varieties

grown

– A method for indicating

harvest and/or pack date

– Harvest/packing crews

1

2

3

How to make your products traceable

Step 1 - Map field production areas

Penn State Extension 2012

Field #1

Field #2

45

A Lot Code Could Identify

• Commodity including type

(e.g., Empire apples)

• Farm/field/block of origin

• Agricultural inputs applied

• Harvest date

• Harvest crew

• Packinghouse used (if any)

• Packing date (if different from harvest date)

• Packing crew (if different from harvest crew)

46

Traceability Example

Farm Location: 10

(Rose Farm)

Block: 01

Fruit Type: 01 (Apples)

Variety: 05 (Empire)

Harvest Date: 284

(Julian date)

Traceback: Finding the Source

▪ Traceback is the ability to identify the source

of a product—important if a foodborne

disease outbreak occurs and you need to find

out where the food came from

▪ A good traceback system can:

⚫ Protect you from false association with an

outbreak

⚫ Minimize consumer anxiety and bad

publicity

⚫ Give you a competitive advantage

Traceback: Summary

▪ At the minimum, you should identify your product with

• Date of harvest and/or date of packing

• Farm identification

▪ Document your handling chain from the farm to your

distributor/customer

▪ Document all aspects of your packinghouse

operations

▪ Get help from industry trade groups for

information on coding, labeling and tools

available to make the job easier

▪ Write an SOP

RECALL PROGRAM

BE PREPARED

Class I: Reasonable public health hazard for illness or death

Class II: Remote probability of adverse health consequences

Class III: Will not cause adverse health consequence

FDA Recalls are Mandatory

52

• Each container/lot leaving the

farm should be identifiable

• Attaching the lot code to the lot

– Many ways to get it done

– Stickers, stamps, bar codes

– Boxes, clamshells, or individual pieces

• Determine the best system for your farm

– Size, markets, costs, infrastructure

– Electronic or paper

Labeling

53

“Must prominently and conspicuously display, at the

point of purchase, the name and complete business

address of the farm where the produce was grown, on

a label, poster, sign, placard…”

Labeling: FSMA Modified Requirements

for Growers Who May Be Exempt

§

54

Testing Your Traceability System:

Conducting a Mock Recall

• Steps in a mock recall

1. Select a lot code for produce that has been sold

2. Call a buyer that received some or all of the lot

3. Tell them you are conducting a MOCK recall

4. Ask how much of the product is in stock and how much

has been sold. Document the response.

5. Trace the lot in your records

(e.g., field of origin, harvest crew, spray records)

6. Can you trace it backward and forward? Yes, good!

No, figure out the problem. Either way, document it!

55

Summary

• The best person to write the plan is someone who knows

the farm and has food safety knowledge

• Identify someone to be in charge of food safety

• Farm Food Safety Plans should include assessing risks, any

actions taken to reduce risks, and recordkeeping

• Simple is best: write what you do, not what you hope to do

• Traceability = one step forward and one step back,

as well as inputs to the crop throughout production

• Establishing lots, lot codes, and labeling are necessary for

developing a traceability system

• Finally, follow the plan and update as necessary