1

Fill-in-the-Blank

POLLUTION PREVENTION PLAN

May 2023

2

POLLUTION PREVENTION PLAN

For

Facility Name: ________________________

Address: _____________________________

Facility ID number: __________________

Facility NAICS: _____________

Base Year: _____________

This Plan Covers Years: ___________

Original Date of Plan: _______________

Revision Date (if any): _______________

3

POLLUTION PREVENTION PLAN

TABLE OF CONTENTS

Page

1. GENERAL INFORMATION ?

2. PERSONNEL INFORMATION AND CERTIFICATIONS ?

3. FACILITY-LEVEL INFORMATION ?

4. PROCESS-LEVEL INFORMATION ?

5. ANNUAL HAZARDOUS WASTE INFORMATION ?

6. PART 1A COST DATA ?

7. SOURCE-LEVEL NPO DATA ?

8. TARGETING ?

9. POLLUTION PREVENTION OPTIONS ?

IDENTIFYING OPTIONS

FEASIBILITY ANALYSIS

TECHNICAL ANALYSIS

FINANCIAL ANALYSIS

10. POLLUTION PREVENTION GOALS ?

11. EXPECTED IMPACT ON MULTI-MEDIA RELEASES ?

12. FACILITY & PROCESS LEVEL REDUCTIONS ?

APPENDIX A: SELF-VERIFICATION OF

MATERIALS ACCOUNTING DATA WORKSHEET ?

APPENDIX B: GROUPING ?

4

1.0 GENERAL INFORMATION

It is recommended that a narrative description of the facility, its products and any other

information pertinent to future pollution prevention planning be included in the

introduction to the Plan. The Introduction should also include, as inserts or addendum on

replacement pages, a summary of any Plan revisions that may have been made during the

year.

5

2.0 PERSONNEL INFORMATION AND CERTIFICATIONS

Personnel Information

Facility Name:

Facility Phone Number:

Physical Address:

Mailing Address:

Owner / Operator of the Facility:

Name:

Title:

Phone: ( ) -

Highest Ranking Corporate Official at the Facility:

Name:

Title:

Phone: ( ) -

Highest Ranking Corporate Official with Direct Operating Responsibility:

Name:

Title:

Phone: ( ) -

Non-Management Employee (Union) Representative:

Name:

Title:

Phone: ( ) -

6

Certifications (N.J.A.C. 7:1K-4.3(b)1)

Highest ranking corporate official at facility with direct operating

responsibility:

"I certify under penalty of law that I have read the Pollution Prevention Plan and

that the Pollution Prevention Plan is true, accurate and complete to the best of my

knowledge."

____________________________________ ____________

Name, Title Date

Highest ranking corporate official at facility:

"I certify under penalty of law that I am familiar with the Pollution Prevention

Plan and that it is the corporate policy of this industrial facility to achieve the goals of the

Pollution Prevention Plan."

____________________________________ __________

Name, Title Date

7

3.0 FACILITY-LEVEL INFORMATION (N.J.A.C. 7:1K-4.3(b)2)

Covered Hazardous Substances

The following TRI hazardous substances are used at this facility above threshold:

Hazardous Substance Name CAS Number Reporting Threshold

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

________________________ ______________ _______________

8

Facility–Level Materials Accounting Information

A complete facility level materials accounting is required for all hazardous substances

used at the facility which exceed the reporting threshold.

One way to satisfy this requirement is to attach a copy of your facility’s annual Release

and Pollution Prevention Report (RPPR).

Another way to display this information is to complete Table 1 below. Table 1 has an

advantage over the RPPR in that it allows you to easily track and compare USE and NPO

from subsequent years. It is recommended that Table 1 be included in the Plan for ease

of comparison in subsequent years, even if the RPPR is included.

The difference between annual inputs and annual output quantities cannot exceed five

percent.

APPENDIX A: SELF-VERIFICATION OF MATERIALS ACCOUNTING DATA

WORKSHEET provides additional guidance for calculating input/output balances.

USE can be calculated using the equation:

USE = Consumed + Shipped (as/in product) + NPO

9

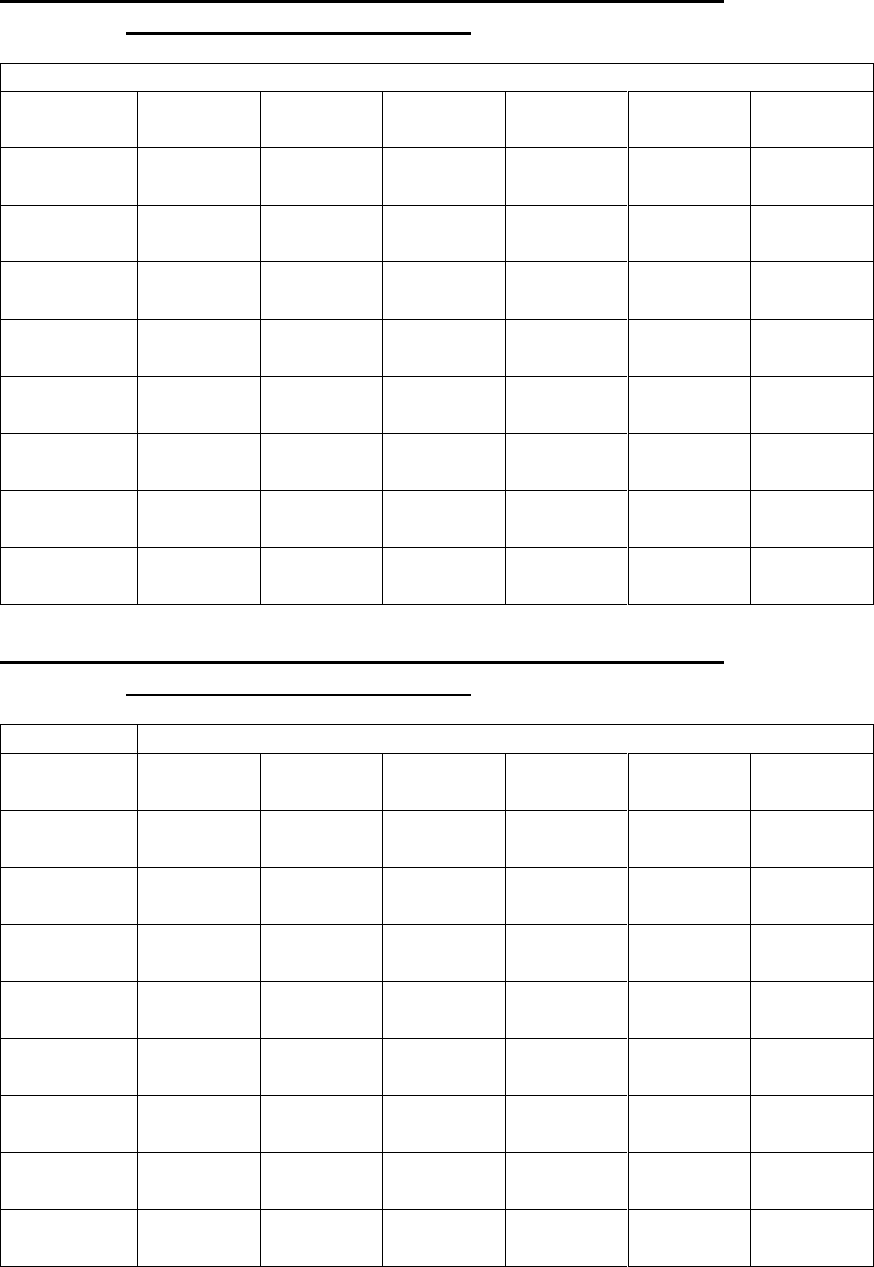

Table 1 Facility-Level Inventory Summary:

Hazardous Substance:

Reporting Threshold:

CAS Number:

Base Year

1st Year

2 nd Year

3 rd Year

4 th Year

5 th Year

INPUTS: (pounds)

Starting inventory

Produced onsite

Brought onsite

Recycled out of process

& re-used onsite

OUTPUTS: (pounds)

Consumed onsite

Shipped offsite as/in

product

Ending inventory

Total NPO

Recycled out of process

& re-used onsite

Destroyed through

onsite treatment

Destroyed through

onsite energy recovery

Release to air through

stack emissions

Release to air through

fugitive emissions

Discharged to POTW

Discharged to surface

waters

Discharge to ground

water

Onsite land disposal

Transferred offsite

USE (pounds)

Inputs must equal outputs within 5% or less.

10

4.0 PROCESS-LEVEL INFORMATION AND INVENTORY DATA

(N.J.A.C. 7:1K-4.3(b)3-4; 7:1K-4.9)

Process–Level Materials Accounting Information

Process level materials accounting data is required for each TRI hazardous substance

used in each process at the facility.

The first step is to identify and provide a description of each process that uses a covered

hazardous substance. One way of presenting this information is to fill in the table below.

Another way to satisfy this requirement is to provide a narrative description of each

process N.J.A.C. 7:1K-4.3(c)2.

The Pollution Prevention Process Level Data Worksheet (P2-115) shown below is

required to be completed and included in your Pollution Prevention Plan.

Facilities may submit P2-115s to the Department in lieu of Sections C and D of the

RPPR.

Three additional items not listed on the P2-115 are also required to be contained in your

Plan:

1) An identification/description of the product(s), co-product(s), and/or

intermediate product(s) produced at the facility.

2) If processes were grouped – a short explanation of why your facility chose to

group the processes. Grouping can make pollution prevention planning easier by

combining several similar processes or sources and treating them as a single

aggregate process or source throughout the P2 Plan.

* Treatment systems that use hazardous substances or generate NPO not

generated elsewhere at the facility are required to be included as separate

sources or production processes.

APPENDIX B: GROUPING provides additional guidance on the grouping

decision as well as an example of inappropriate grouping.

3) A process flow diagram is required to be in the P2 Plan. The necessary

components of a process flow diagram are raw material inputs, products, and

nonproduct outputs and an explanation of the steps that turn input into product

and nonproduct output.

Calculating USE and NPO on the P2-115:

USE = Consumed + Shipped (as/in product) + NPO

(On the P2-115 shown below USE is the sum of the items shown in red.)

NPO = Calculated by summing the data elements shown in blue on the form

below (i.e., from “Recycled out of process” down to “End. Inv. as NPO – Beg. Inv. as NPO”)

11

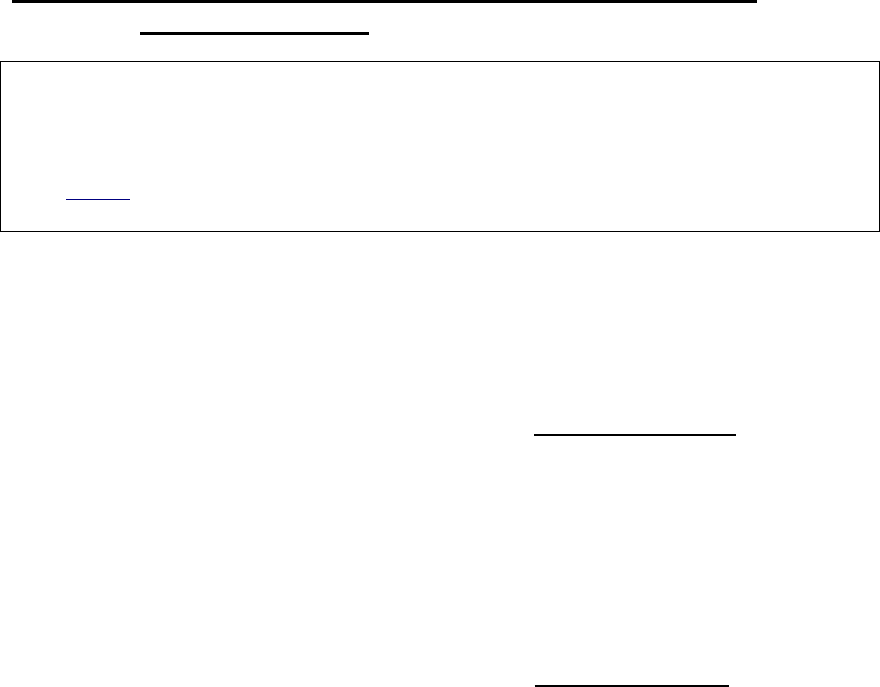

POLLUTION PREVENTION PROCESS-LEVEL DATA WORKSHEET (P2-115)

Use one worksheet for each hazardous substance in each process.

Base Year ___________

FACID

Process ID (from P2 Plan Summary)

__________________

Units of Production (e.g. type of “widget,”

lbs. Of chemical, square feet of product)

__________________

Is process targeted? (Y/N)

__________________

Is this a grouped process? (Y/N)

__________________

Facility Location

CAS No.: __________________________ Hazardous Substance: _______________________________________

Base Year

Year 1

Year 2

Year 3

Year 4

Year 5

Production quantity

USE (pounds)

Consumed

Shipped off-site as (or in) product

NPO (pounds)

Recycled out of process

Destroyed: on-site treatment

Destroyed: on-site energy recovery

Stack air emissions

Fugitive air emissions

Discharge to POTWs

Discharge to surface waters

Discharge to groundwater

On-site land disposal

Transferred off site

End. Inv. as NPO minus Beg. Inv. as NPO

P2 techniques used in given year

(see codes in RPPR Appendix E)

Was this process discontinued or sent off site

in the given year? (Y/N)

Did facility make process change(s) that

triggered a Plan modification? (Y/N)

Was facility's P2 progress (targeted process

only) less than anticipated? (Y/N)

CERTIFICATION OF OWNER OR OPERATOR - I certify under penalty of law that the information submitted in this Pollution Prevention Plan

Progress Report is true, accurate and complete to the best of my knowledge. (Signature required on only one P2-115.)

Signature: ______________________________________________ Date: _________________ Phone No: (______)____________________________

Name: _________________________________________________ Title: ______________________________________________________________

Note: This worksheet is required as part of the Pollution Prevention Plan, and is optional as a submittal in lieu of

Sections C and D of the Release and Pollution Prevention Report. All optional submittals are not

confidential.

12

5.0 ANNUAL HAZARDOUS WASTE GENERATION,

TREATMENT, STORAGE AND DISPOSAL

(N.J.A.C. 7:1K-4.3(b)5)

The Rules require that information on annual “hazardous waste” generation, treatment,

storage, and disposal and amounts of waste generated for each process be included in

the Plan. This includes all “hazardous waste,” not just wastes containing TRI

“hazardous substances” regulated under the P2 Program.

“Hazardous Substance” refers to TRI substances and is defined by the Pollution

Prevention Act to mean any substance on the list established by the United States

Environmental Protection Agency for reporting pursuant to 42 U.S.C. §11023, and any

other substance which the Department defines as a hazardous substance for the purposes

of the Act pursuant to N.J.A.C. 7:1K-3.5.

“Hazardous waste” refers to RCRA regulated waste and is defined by the Pollution

Prevention Act to be any solid waste defined as hazardous by the Department pursuant to

the hazardous waste statute (N.J.S.A. 13:1E-1 et seq.).

In addition to your RCRA Hazardous Waste Biennial Report, alternate year’s data must

be included in your Plan.

Completion of this section with all hazardous wastes meets the waste minimization

planning requirements under RCRA. All hazardous wastes must be reported whether or

not they contain a covered substance under pollution prevention planning.

13

Table H-1 Facility-Level Inventory of Hazardous Waste:

This table contains information covered under N.J.A.C. 7:1K-4.3(b)5i-ii.

Name of covered

substance in waste:

CAS No.

Hazardous waste

Category

Amount generated

Amount treated outside

of a production process

Amount stored outside

of a production process

Amount disposed

outside of a

production process

Address of off-site

TSD facility receiving

the waste

Description of the type

of treatment method

used at each TSD

Amount recycled onsite

Amount recycled

offsite

Hazardous waste inventory data must be completed annually.

14

Table H-2 Process-Level Inventory of Hazardous Waste:

This table contains information covered under N.J.A.C. 7:1K-4.3(b)5iii.

Process Name

Hazardous Waste Type

Quantity Generated (lbs.)

Hazardous waste inventory data must be completed annually.

15

6.0 PART IA COST DATA (“the cost of doing business as usual”) is

located in Table C-1 of section 9.0 along with the Part II cost

analysis (“the estimate of costs to determine potential savings

associated with implementing a P2 option”).

16

PART II OF THE PLAN

N.J.A.C.7:1K-4.5

7.0 SOURCE-LEVEL NPO DATA (N.J.A.C. 7:1K-4.5(a)2)

Table S-1 Source-Level Inventory of NPO:

Process Name

Source of NPO

Quantity Generated (lbs.)

17

8.0 TARGETING (N.J.A.C.7:1K-4.4)

Targeting of Sources/Processes

The Rules allow a facility to concentrate pollution prevention resources on a process or

processes which account for a significant amount of USE, NPO, or Releases at the

facility (a significant amount is defined to be at least 90%).

Targeting is required for facilities that use or generate Persistent, Bioaccumulative, and

Toxic (PBT) substances at or above the reporting threshold - see note below. Targeting

will be of no help to facilities that have only one process; however, it may prove

beneficial to facilities with numerous processes.

Again, there are several ways to present this information. One way to satisfy this

requirement is to provide a narrative description of your targeted process or processes

which explains why you targeted each process and indicates the percent of USE, NPO, or

Releases the process or processes cover. Another way of presenting this information is to

fill in Table T-1 below.

Note: All processes or sources at covered facilities that use or generate PBTs above

reporting thresholds are required to be targeted for P2 Planning.

Table T-1 Targeted Process Justification:

This table contains information covered under N.J.A.C. 7:1K-4.4(b).

Process Name

Targeted?

(Y/N)

Basis for Targeting

(USE, NPO, or Releases)

Percent covered

by this process

18

9.0 POLLUTION PREVENTION OPTIONS (N.J.A.C. 7:1K-4.5(a)4)

Identifying Options

Facilities are required to list and evaluate potential pollution prevention options that may

reduce the use and or generation of hazardous substances. However, the rules do not

require facilities to implement any of the options identified in the Pollution Prevention

Plan, implementation is strictly voluntary. The rule is designed to help facilities

assemble data and identify ways to prevent pollution and increase efficiency, which in

turn may lead to cost savings and environmental benefits. The intent is that if facilities

identified ways to reduce waste and save money, they would implement the options on

their own accord.

There are three steps to follow:

1) List all potential options.

2) Perform a Technical Analysis of each option.

3) Perform a Financial Analysis of technically feasible options.

The first thing to do is list all available options, not just the options you plan to

implement. Listing all options allows you to document for future Plan revisions (and for

the benefit of the next person assigned to prepare or update the Plan) all options

considered and will allow you to disregard the option if future conditions remain the

same or revisit the option if conditions at the facility have changed (e.g., the price of a

raw material becomes too expensive, new technology becomes affordable, etc.). This

information may be presented as a narrative or in tabular form (see Table O-1 below).

Table O-1 Description of Pollution Prevention Options:

Option

Number

Description of Option

Processes

Affected

Sources

Affected

19

Technical Analysis

A Technical Analysis is performed on all options and is simply a discussion as to whether or

not the option is possible to implement. Depending on the option, some technical analyses

may be very descriptive and detailed while others may be short and concise. In any case, the

cost of implementation is NOT considered in the Technical Analysis. The Technical Analysis

simply answers the question “is the option possible to implement?” A narrative description

is usually the easiest way to present this information; however, Table O-2 is provided below

for those who prefer to present the information in a tabular format.

Table O-2 Technical Analysis of Pollution Prevention Options:

This table contains information covered under N.J.A.C. 7:1K-4.5(a)5i.

Option

Number

Is it

Feasible?

(Y/N)

Will it be

implemented in

the next five

years? (Y/N)

Description of Option

Explanation

20

Financial Analysis

A Part II Financial Analysis (“the costs or savings associated with implementing a P2

option”) is only required for those options that are found to be technically feasible. The

Financial Analysis compares the cost of using, generating, and releasing hazardous

substances, required under 7:1K-4.3(b)6, with the cost or saving which may be incurred

through the implementation of a particular pollution prevention option. This type of

information is best displayed in tabular form. The cost information required in 7:1K-

4.3(b)6 (Part IA - “the cost of doing business as usual”) and 7:1K-4.5(a)5ii (Part II - “the

estimate of costs to determine potential savings associated with implementing a P2

option”) have been combined in Table C-1, below. Facilities may wish to include other

costs pertinent to their particular operation in order to understand the cost/benefits

associated with using a hazardous substance or implementing a P2 option.

Table C-1 Financial Analysis of Pollution Prevention Options:

This table contains information covered under N.J.A.C. 7:1K-4.3(b)6 and 4.5(a)5ii.

Option Number:

Cost associated with

using hazardous

substances.

(“Part 1A cost data”)

Cost to determine

potential savings

associated with the

implementation

of P2 option.

(“Part II cost analysis”)

Net Savings

(+ or -)

OSHA compliance

Consultants fees

Storage & handling

Monitor, track, report

Treatment

Transport. & disposal

Permit fees

Liability insurance

Overhead

Raw material purchase

Operations &

maintenance savings

Capital costs

R&D

Training

Other Costs

Total

21

Selection of Pollution Prevention Options

Table O-3 below summarizes which pollution prevention options your facility intends to

implement over the course of the five-year planning cycle.

Table O-3 Pollution Prevention Options which will be

Implemented during this Five Year Planning Cycle:

This table contains information covered under N.J.A.C. 7:1K-4.5(a)6 & 11.

Option

Number

Description of Option

Is it

Feasible?

(Y/N)

Explanation

22

10.0 POLLUTION PREVENTION GOALS

The rules require that the Plan provide the following:

1) Five-year Facility-level USE and NPO reduction goals.

2) Targeted process-level USE and NPO per unit product.

The first step is to calculate source-level data on expected reductions in targeted

processes due to the implementation of pollution prevention options (see Table G-1).

The next step is to sum the targeted process-level expected reductions that will yield

projected facility-level reductions for each hazardous substance as shown (see Table G-

2). Percent goals can then be calculated for the entire facility (see Table G-3).

The data in Table G-4 is then used to perform a per-unit-of-product analysis, which then

is used to calculate per-unit-of-product goals in percentages for each process as required.

Table G-1 Expected Source-Level USE and NPO Reductions (lbs.):

This table contains information covered under N.J.A.C. 7:1K-4.5(a)9 & 10.

Source

Option Number

Expected USE

Reduction (lbs.)

Expected NPO

Reduction (lbs.)

23

Table G-2 Projected Process-Level USE and NPO Reduction

Goals in Pounds and Percent:

Process:

Hazardous

Substance:

Original

NPO (lbs.)

Reduction

(lbs.)

New NPO

(lbs.)

%NPO

Goal

Original

USE

Reduction

(lbs.)

New USE

(lbs.)

% USE

Goal

Table G-3 Projected Facility-Level USE and NPO Reduction

Goals in Pounds and Percent:

Quantity of hazardous substance (lbs.)

Hazardous

Substance:

Original

NPO (lbs.)

Reduction

(lbs.)

New NPO

(lbs.)

%NPO

Goal

Original

USE (lbs.)

Reduction

(lbs.)

New USE

(lbs.)

% USE

Goal

24

Facility

% NPO Goal = Original NPO - New NPO x 100

Original NPO

Facility

% USE Goal = Original USE - New USE x 100

Original USE

Table G-4 Process-Level Analysis of USE and NPO per Unit of Product

for each Hazardous Substance (Calculated from P2-115 Data):

This table contains information covered under N.J.A.C. 7:1K-4.5(a)7 & 8.

Process:

Hazardous

substances:

Unit of

Product

Orig.

NPO/ Unit

Of Product.

Reduction

New NPO/

Unit of

Product

%NPO

Goal

Orig.

USE/Unit of

Product

Reduction

New

USE/Unit of

Product

% USE

Goal

25

11.0 EXPECTED IMPACT OF IMPLEMENTED OPTIONS ON

POST-TREATMENT MULTI-MEDIA RELEASES

Table I-1 Expected Multi-media Releases (lbs.):

Media

Hazardous Substance:

Base Year

Air

Waste

Water

Fifth Year

Air

Waste

Water

% Reduction

Air

Waste

Water

26

INFORMATION REQUIRED IN THE POLLUTION PREVENTION PROGRESS

REPORT (Sections C & D of the RPPR)

PART IB OF THE PLAN (N.J.A.C.7:1K-4.3(c))

12.0 FACILITY-LEVEL INFORMATION ON REDUCTIONS

The Pollution Prevention Program rules include two progress reporting options. Both

options are intended to provide information about the progress your facility has made

toward the pollution prevention goals that were established in your P2 Plan and reported

to the Department in your P2 Plan Summary.

Option 1 – Submission of the Pollution Prevention Process-Level Data Worksheet (P2-

115). The P2-115 is the DEP-recommended approach to satisfy the Pollution Prevention

Progress Report requirement.

Option 2 – Submission of Sections C and D of the Release and Pollution Prevention

Report (RPPR).

The instructions on the following pages pertain only to reporting Option 2 – Sections C

and D of the RPPR. To simplify the progress report calculations, the information on the

P2-115s contained in the P2 Plan will be used to calculate Sections C and D.

Calculations must be included in the P2 Plan and the results of the calculations must be

submitted on the RPPR. Even if no options have been implemented or zero goals were

set, calculations for all substances must be performed annually to determine progress on

USE and NPO, and must be included in the P2 Plan.

Even if the P2-115 Worksheet(s) are not submitted, the P2-115 Worksheet(s) must still be

prepared and be in the Pollution Prevention Plan.

27

Section C: Facility-Level Substance-Specific Pollution

Prevention Progress

Production Ratio - The production ratio normalizes the variation in units produced from

one year to the next. Choosing an appropriate unit of product in the P2 Plan is critical to

developing a useful production ratio. This information should have already been

collected for all of the production processes.

The example below illustrates the use of process-level data to develop facility-level

progress from the P2-115s. Refer to the abbreviated P2-115s to identify the variables (by

letter) in the formulae.

The formula for calculating the Production Ratio relative to the Base Year (PR

BY

) is as

follows:

For the simplest scenario, when one substance is only used in one process, the

formula for calculating the Production Ratio to the Base Year (PR

BY

) is as

follows:

H

PR

BY

=

A

For those facilities that use one substance in multiple processes, the following

formula applies:

[(H / A * C) + (T/ M * O)]

PR

BY

=

(C + O)

The formula for calculating the Production Ratio relative to the Previous Year (PR

PY

) is

as follows:

The formula for calculating the Production Ratio to the previous year for a

substance in a single process is:

H

PR

PY

=

G

For calculating the Production Ratio using one substance in multiple processes,

the formula is:

[(H / G * I) + (T / S * U)]

PR

PY

=

(I + U)

If the same substance is used in more than two (2) processes, treat the additional

processes identical to the way the second process was added to the example of the single

process (i.e., add all process-level information to obtain facility-level information).

28

Percent Change for USE and NPO - Calculate the percent change (reduction, increase,

or no change) in total facility-wide use and total facility-wide NPO generated for each

substance from the Base Year to this Reporting Year (current year).

Percent Change for USE

for a substance for a single process:

[(C * PR

BY

) - J]

Percent Change for USE

= *100

C * PR

BY

Percent Change for USE

for a substance in multiple processes:

[(C + O) * PR

BY

- (J + V)]

Percent Change for USE = * 100

(C + O) * PR

BY

Percent Change for NPO for a substance in a single process:

[(E * PR

BY

) - L]

Percent Change for NPO = * 100

E * PR

BY

Percent Change for NPO for a substance in multiple processes:

[(E + Q) * PR

BY

- (L + X)]

Percent Change for NPO = * 100

(E + Q) * PR

BY

A positive result means a reduction and a negative result means an increase. If P2

progress is negative, the electronic system will require a check box to be checked and an

explanation given.

29

The following two P2-115s are abbreviated to illustrate the variables needed to calculate

the Production Ratio (PR) and the Percent Change for USE and NPO.

POLLUTION PREVENTION PROCESS-LEVEL DATA WORKSHEET (P2-115)

Base Year 2025

FACID: 12345600000

ACME MANUFACTURING

PO BOX 12345

ANYWHERE, NJ 90210

Process ID (from P2 Plan Summary)

WIDGETLINE

Units of Production (e.g. type of

“widget,” lbs. of chemical, square feet of

product)

Widgets

Is process targeted? (Y/N)

Y

Is this a grouped process? (Y/N)

Y

CAS No.: 108-88-3

Hazardous Substance: Toluene

Base Year

2026

2027

2028

2029

2030

Production quantity (widget, lbs., ft

2

, etc.)

A

B

G

H

USE (pounds)

C

D

I

J

Consumed

Shipped off-site as (or in) product

NPO (pounds)

E

F

K

L

POLLUTION PREVENTION PROCESS-LEVEL DATA WORKSHEET (P2-115)

Base Year 2025

FACID: 12345600000

ACME MANUFACTURING

PO BOX 12345

ANYWHERE, NJ 90210

Process ID (from P2 Plan Summary)

THINGAMABOBS

Units of Production (e.g. type of

“widget,” lbs. of chemical, square feet of

product)

Thingamabobs

Is process targeted? (Y/N)

Y

Is this a grouped process? (Y/N)

Y

CAS No.: 108-88-3

Hazardous Substance: Toluene

Base Year

2026

2027

2028

2029

2030

Production quantity (widget, lbs., ft

2

, etc.)

M

N

S

T

USE (pounds)

O

P

U

V

Consumed

Shipped off-site as (or in) product

NPO (pounds)

Q

R

W

X

30

In Table R-1, the first two columns are the actual USE and NPO amounts independent of

production. The Actual USE and NPO reductions (%) take into account the Production

Ratio as calculated above.

Table R-1 Facility-Level Information on Reduction Quantities (lbs.):

Year

USE

(lbs.)

NPO

(lbs.)

USE

Reduction

Goal (%)

Actual

USE

Reduction

(%)

NPO

Reduction

Goal (%)

Actual

NPO

Reduction

(%)

Base

Year

Year

1

+ / -

Year

2

+ / -

Year

3

+ / -

Year

4

+ / -

Year

5

+ / -

31

Section D: Process-Level Pollution Prevention Information for

Targeted Processes

Complete one Section D for each targeted process or targeted grouped process

To complete Section D, refer to the units of product, which were identified in the P2

Plan. Once the appropriate units of product have been determined from the P2 Plan, the

units cannot be changed in subsequent years, unless the P2 Plan, P2 Plan Summary, and

previous P2 Progress Reports have been modified.

Percent Change for USE - State the total progress made toward achieving each substance-

specific process-level pollution prevention goal for USE identified in the P2 Plan and in

the P2 Plan Summary submitted to the DEP. (Refer to the P2-115 for Toluene in process

“Thingamabobs” for the variables in the following formula.)

[(O / M) - (V / T)]

Percent Change for USE = * 100

(O / M)

Percent Change for NPO - State the progress made toward achieving each substance-

specific process-level pollution prevention goal for NPO identified in the P2 Plan and in

the P2 Plan Summary submitted to the DEP. (Refer to the P2-115 for Toluene in process

“Thingamabobs” for the variables in the following formula.)

[(Q / M) - (X / T)]

Percent Change for NPO = * 100

(Q / M)

32

Table R-2 shows process-level information on reductions in USE and NPO for targeted

processes.

Table R-2 Process-Level Information on Reductions for

Targeted Process(es):

Year

No. of

Units of

Prod.

USE

(lbs.)

USE/

Unit

Prod.

NPO

(lbs.)

NPO/

Unit

Prod.

USE/

Unit

Prod.

Reduct.

Goal

(%)

Actual

USE/

Unit

Prod.

Reduct.

(%)

NPO/

Unit

Prod.

Reduct.

Goal

(%)

Actual

NPO/

Unit

Prod.

Reduct.

(%)

Base

Year

Year

1

+ / -

Year

2

+ / -

Year

3

+ / -

Year

4

+ / -

Year

5

+ / -

1

APPENDIX A: SELF-VERIFICATION OF MATERIALS ACCOUNTING DATA WORKSHEET

(All Quantities Must Be Reported in Pounds except for Dioxin and Dioxin-Like Compounds Reported in Grams)

This table is included to allow the balancing of inputs and outputs to within 5% as required at N.J.A.C. 7:1K-4.3(b)2x.

CAS#: __________ Substance: ___________________________

Inputs

Outputs

5.

Starting Inventory

8.

Quantity Consumed

(chemically reacted)

6.

Quantity Produced

On Site

9.

Quantity Shipped Off Site

as (or in) Product

7.

Quantity Brought On Site

10.

Ending Inventory

12.

Quantity Recycled Out-of-Process

& Re-Used On Site

12.

Quantity Recycled Out-of-Process

& Re-Used On Site

13.

Quantity Destroyed through

On-Site Treatment

14.

Quantity Destroyed through

On-Site Energy Recovery

15.

Stack Air Emissions

16.

Fugitive Air Emissions

17.

Discharge to POTWs

18.

Discharge to Surface Waters

19.

Discharge to Groundwaters

20.

On-Site Land Disposal

21.

Other Off-Site Transfers

Sum of Inputs:

Sum of Outputs:

1

APPENDIX B: GROUPING

Grouping makes pollution prevention planning easier by combining several similar

processes and treating them as a single aggregate process throughout the Pollution

Prevention Plan. Grouping focuses your attention on whether your similar operations are

being run consistently.

Grouping reduces the workload surrounding pollution prevention because it shrinks the

number of processes that must be studied by identifying “grouped processes” that

represent their component processes in the Pollution Prevention Plan. Grouping does not

eliminate anything from consideration in the Plan, but it does organize what must be

considered in a more manageable way.

When grouping, the object is to collect several processes together, which are similar

enough in terms of their products, material use, and process steps to be treated as a single

process. Grouping simplifies process evaluation by minimizing the number of times data

needs to be collected or recorded. Remember that once you have grouped processes

together, they will remain grouped throughout the Plan.

Grouping is NOT a required step in pollution prevention planning. Poorly grouped

processes create situations where the data collected for a grouped process does not apply

to some of its components.

As an example of grouping processes inappropriately, consider a paint manufacturer

that produces several colors of both oil-based and latex-based paints. Using color as the

only criterion for grouping would be inappropriate. It could lead to “yellow oil-based

paint” and “yellow latex-based paint” being in the same grouped process. Logically, the

latex and oil products should be in separate groups since they are manufactured using

different types of chemicals. Color could be a criterion to further group the processes,

within the latex and oil groups, to address any concerns with heavy metal content of the

pigments, which may vary by color.