Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

Supersedes Publication BATCH-UM003B-EN-D - May 2022

Administrator Guide

Original Instructions

FactoryTalk Batch

Administrator Guide

FactoryTalk Batch Administrator Guide

2 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING:

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

personal injury or death, property damage, or economic loss.

ATTENTION:

Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD:

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD:

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

ARC FLASH HAZARD:

Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash will

cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and for

Personal Protective Equipment (PPE).

Rockwell Automation recognizes that some of the terms that are currently used in our industry and in this publication are not in

alignment with the movement toward inclusive language in technology. We are proactively collaborating with industry peers to

find alternatives to such terms and making changes to our products and content. Please excuse the use of such terms in our

content while we implement these changes.

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 3

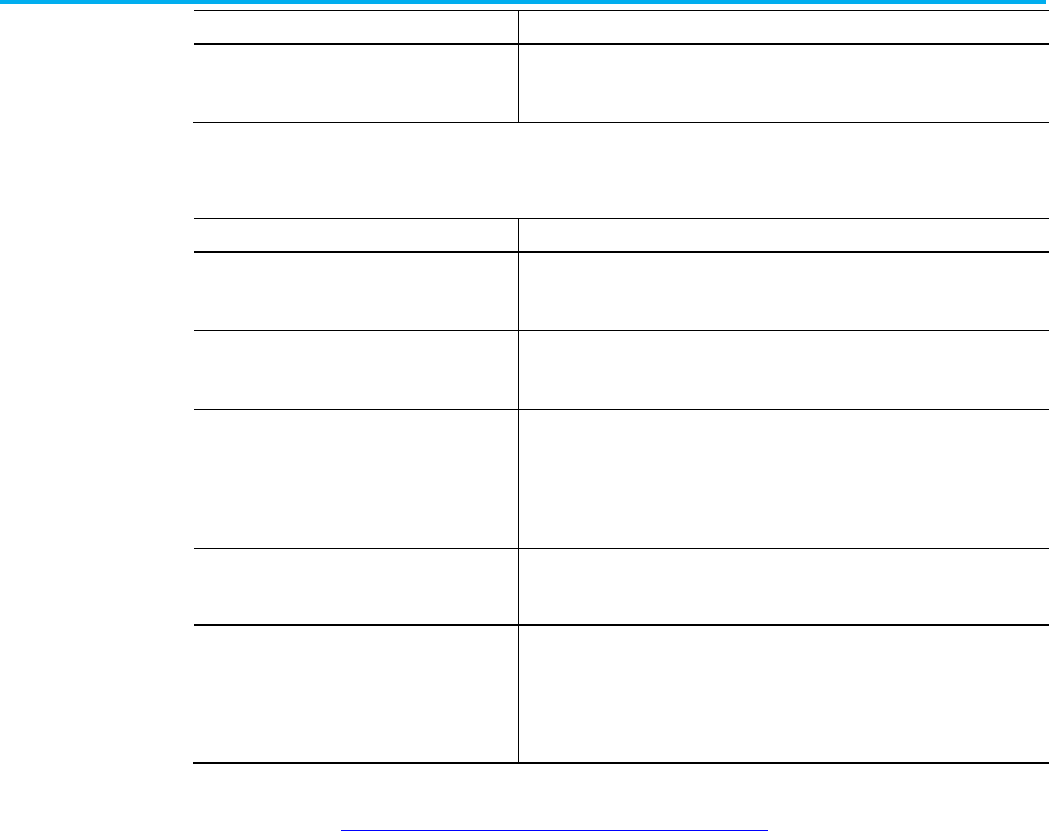

Summary of changes in FactoryTalk Batch Administrator Guide

This publication contains this new or updated information. This list includes

substantive updates only and is not intended to reflect all changes.

Topic

Reason for change

Event File Format on page 86

Functional change

Updated all screen captures Usability improvement

Use Open Platform Communications on page 17 Clarification

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 5

Table of Contents

About this manual ....................................................................................... 11

Document organization ............................................................................. 11

Legal Notices ............................................................................................... 11

Additional resources .................................................................................. 12

Chapter 1

FactoryTalk Batch regional settings ......................................................... 15

Chapter 2

Create a shared directory .......................................................................... 17

Use Open Platform Communications (OPC) ........................................... 17

OPC group support .............................................................................. 18

Chapter 3

FactoryTalk Batch Server user account configuration requirements ... 19

FactoryTalk Batch system configuration .................................................20

System-wide COM security limit settings ........................................ 20

FactoryTalk Batch Server install configuration ................................. 21

FactoryTalk Batch Windows Firewall exceptions .............................. 21

Add the Batch COM service ................................................................ 22

Set security on folders or files ...................................................................23

Add users and user groups ................................................................. 24

Change permissions on the BATCHCTL share ................................. 24

FactoryTalk Security for the Batch Clients .............................................. 25

Tighten security for FactoryTalk Batch Clients ................................ 26

FactoryTalk Batch Equipment Editor and FactoryTalk Batch Recipe

Editor security ........................................................................................... 27

Configure access mode security ........................................................ 28

Configure feature security ................................................................. 28

Modify FactoryTalk Batch Equipment Editor configuration options

.............................................................................................................. 29

Chapter 4

Product policies in the local and network directories ..............................31

BatchCampaign policy settings ................................................................ 32

BatchView policy settings ......................................................................... 32

Equipment Editor policy settings ............................................................. 34

Recipe Editor policy settings ..................................................................... 34

Chapter 5

Summary of changes in

FactoryTalk Batch

Administrator Guide

Preface

FactoryTalk Batch components

FactoryTalk Batch

communications

FactoryTalk Batch security

FactoryTalk Batch default

policy settings

Table of Contents

6 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

Command verification policies................................................................. 38

Command signature requests ............................................................. 38

Set parameter signature request ........................................................ 40

FactoryTalk Batch Parameter Prompt Acknowledge Signature

request .................................................................................................. 41

Unit Bind Prompt Acknowledge Signature request ......................... 42

Phase Bind Prompt Acknowledge Signature request ...................... 42

Unit Bind Signature request ............................................................... 43

Remove Batch Signature request ....................................................... 44

Add Event Signature request .............................................................. 45

Active Step Change Signature request ............................................... 45

Parameter deviation verification policies ............................................... 46

Parameter deviation signature requests ............................................ 47

Report parameter deviation signature requests ............................... 48

General usage phase logic requests ......................................................... 48

General usage signature requests ...................................................... 48

Electronic signature security.................................................................... 49

Configure the ESignature network directory policy setting ........... 50

Chapter 6

Enable auditing for FactoryTalk Batch Equipment Editor or

FactoryTalk Batch Recipe Editor .............................................................. 52

Audited FactoryTalk Batch Equipment Editor events ............................ 52

Audited FactoryTalk Batch Recipe Editor events ..................................... 55

Audit messages ........................................................................................... 56

FactoryTalk Diagnostics Viewer ......................................................... 57

Standard viewer message fields in FactoryTalk Diagnostics

Viewer ............................................................................................ 58

Extended viewer message fields in FactoryTalk Diagnostics

Viewer ............................................................................................ 58

FactoryTalk AssetCentre Client ......................................................... 60

Viewer message fields .......................................................................... 61

Chapter 7

Windows services ...................................................................................... 63

FactoryTalk Batch Service Manager dialog box ....................................... 64

Verify/Deploy Area Model dialog box ................................................. 65

FactoryTalk Batch Server Details dialog box ..................................... 66

FactoryTalk Batch Server Details dialog box - General tab ........ 66

FactoryTalk Batch Server Details dialog box - Messages tab ...... 67

FactoryTalk Batch Server Details dialog box - PCD

Communications tab ..................................................................... 67

FactoryTalk Batch electronic

signatures

FactoryTalk Batch audit trail

The FactoryTalk Batch Service

Manager

Table of Contents

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 7

FactoryTalk Batch Server Details dialog box - View

Communications tab .................................................................... 68

Start the FactoryTalk Batch Server service .............................................. 68

Grace periods in FactoryTalk Batch Server ....................................... 69

Enable a grace period .......................................................................... 70

Add a custom service ................................................................................. 70

Chapter 8

FactoryTalk Batch Server service configuration ..................................... 73

Specify the startup type ....................................................................... 73

FactoryTalk Batch Server option configuration ...................................... 74

Server Options dialog box - Project Settings tab ............................... 74

Set project directories .................................................................... 75

Configure recipe storage ............................................................... 76

Recipe versioning ........................................................................... 76

Server Options dialog box - Restart Control tab ................................ 77

Redundant servers ......................................................................... 77

Server Options dialog box - Batch Reporting tab .............................. 79

Perform end of batch archiving ................................................... 80

Perform incremental archiving .................................................... 81

Perform user-defined end of batch ............................................. 82

Never .............................................................................................. 82

Archiver Event Filters tab ................................................................... 82

Batch Server tab .................................................................................. 83

Hold propagation .......................................................................... 84

Communications timeout ............................................................ 85

Miscellaneous ................................................................................ 86

Event File Format .......................................................................... 86

Cross Invocation Descriptors and Defaults tab ................................ 87

Resource types ............................................................................... 87

Descriptors .................................................................................... 87

Default values ................................................................................ 88

Hyperlink Descriptors and Defaults tab ........................................... 88

Material Policies tab ............................................................................ 88

Modify the .NET registry key .................................................................... 90

Use automatic restart control to restart the FactoryTalk Batch Server 90

Restart the FactoryTalk Batch Server ................................................ 90

Perform a manual failover ......................................................................... 91

Configure the FactoryTalk Batch Server for manual failover ........... 91

Configure the material-enabled FactoryTalk Batch Server for

manual failover .................................................................................... 92

Command handshake timeout .................................................................. 93

The FactoryTalk Batch Server

Table of Contents

8 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

Chapter 9

Update an online area model .................................................................... 96

Verify and deploy an updated area model using the FactoryTalk Batch

Service Manager ......................................................................................... 97

Review the Compare/Update log ............................................................. 98

Resolve runtime condition checks ........................................................... 99

Update global area model ....................................................................... 100

Data server definitions in area model .................................................... 107

Update enumerations in area model ......................................................108

Update operation sequences in area model ........................................... 109

Phases and classes in area model ............................................................ 116

Update messages in an area model................................................... 122

Control strategy in an area model .................................................... 122

Parameters and reports in area model ............................................. 124

Process cells and classes in area model................................................... 125

Resources and classes in area model ...................................................... 126

Signature templates in area model ......................................................... 128

Units and classes in area model .............................................................. 128

Update unit attributes and tags in an area model ............................ 131

Chapter 10

View event log entry properties ............................................................... 135

Modify event log settings ........................................................................ 138

Chapter 11

Cross invocation overview ....................................................................... 141

Cross invocation string configuration ................................................... 142

Cross invocation string escape sequences ............................................. 143

Chapter 12

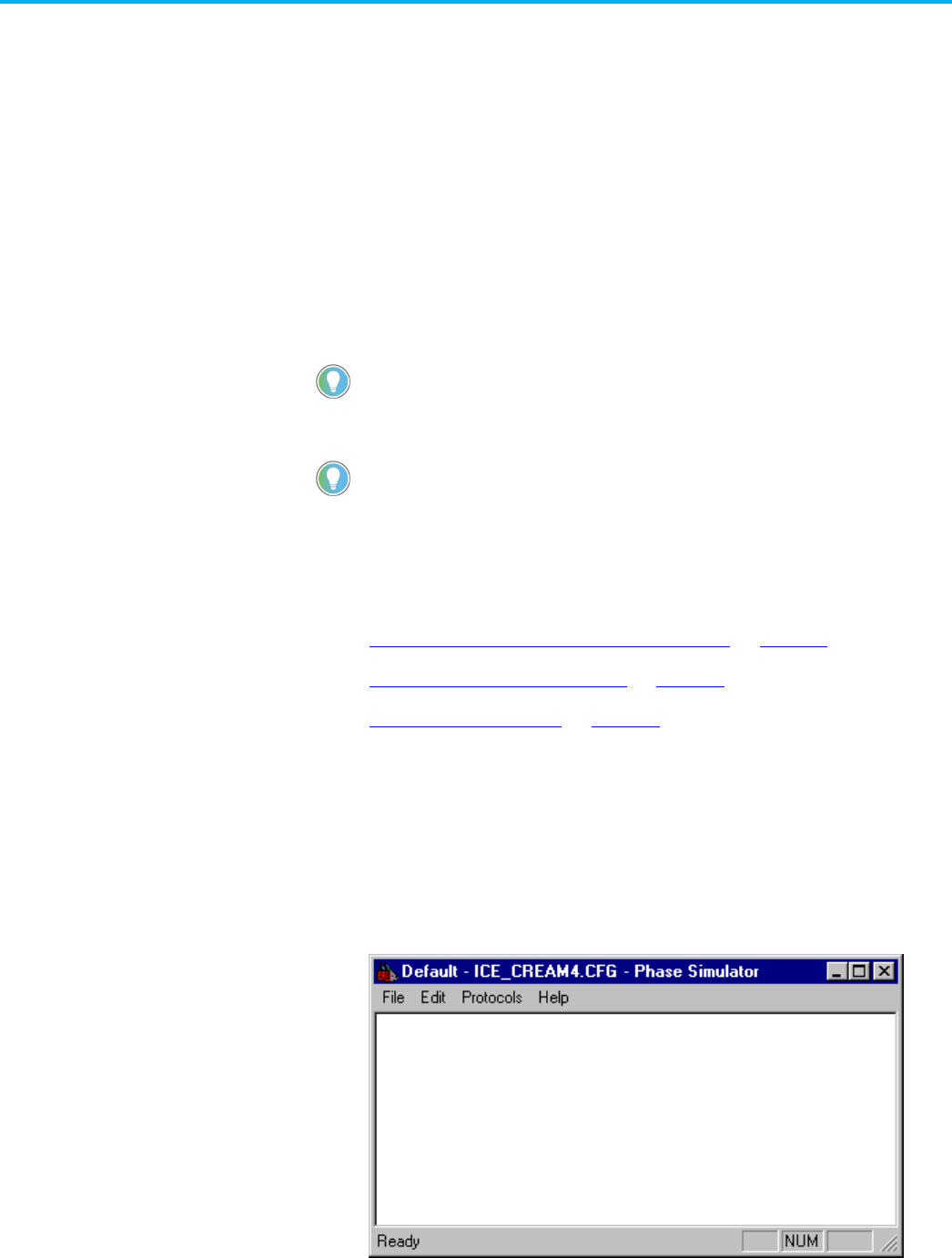

Start the FactoryTalk Batch Phase Simulator ......................................... 145

FactoryTalk Batch Phase Simulator interface .................................. 146

Phase Configuration dialog box ............................................................. 146

Change the dwell time ....................................................................... 147

Change the sequence of requests ...................................................... 148

Indicate a continuous phase ............................................................. 148

Phase Status dialog box ........................................................................... 149

View phase parameter tag values ...................................................... 149

View and update report parameter tag values ................................. 150

View request data tag values ............................................................. 150

Change ownership of a phase ........................................................... 151

Command a phase .............................................................................. 151

Area models

Windows event log

Cross invocation

The FactoryTalk Batch Phase

Simulator

Table of Contents

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 9

Phase commands ......................................................................... 152

Acknowledge and clear a request ...................................................... 153

Restore and clear requests ................................................................. 153

Unit Tag Status dialog box ....................................................................... 154

Change the value of a unit tag ........................................................... 155

Chapter 13

Open the Network Editor ......................................................................... 157

Network Editor interface ......................................................................... 157

Hierarchy pane ................................................................................... 158

Detail pane .......................................................................................... 158

Results pane ........................................................................................ 159

Menu bar and toolbar ........................................................................ 160

Network Editor toolbar ...................................................................... 160

Status bar ............................................................................................ 161

Configure your network .......................................................................... 161

Select a network model ...................................................................... 161

Add a server ........................................................................................ 162

Remove a server.................................................................................. 162

Synchronize network models ............................................................ 162

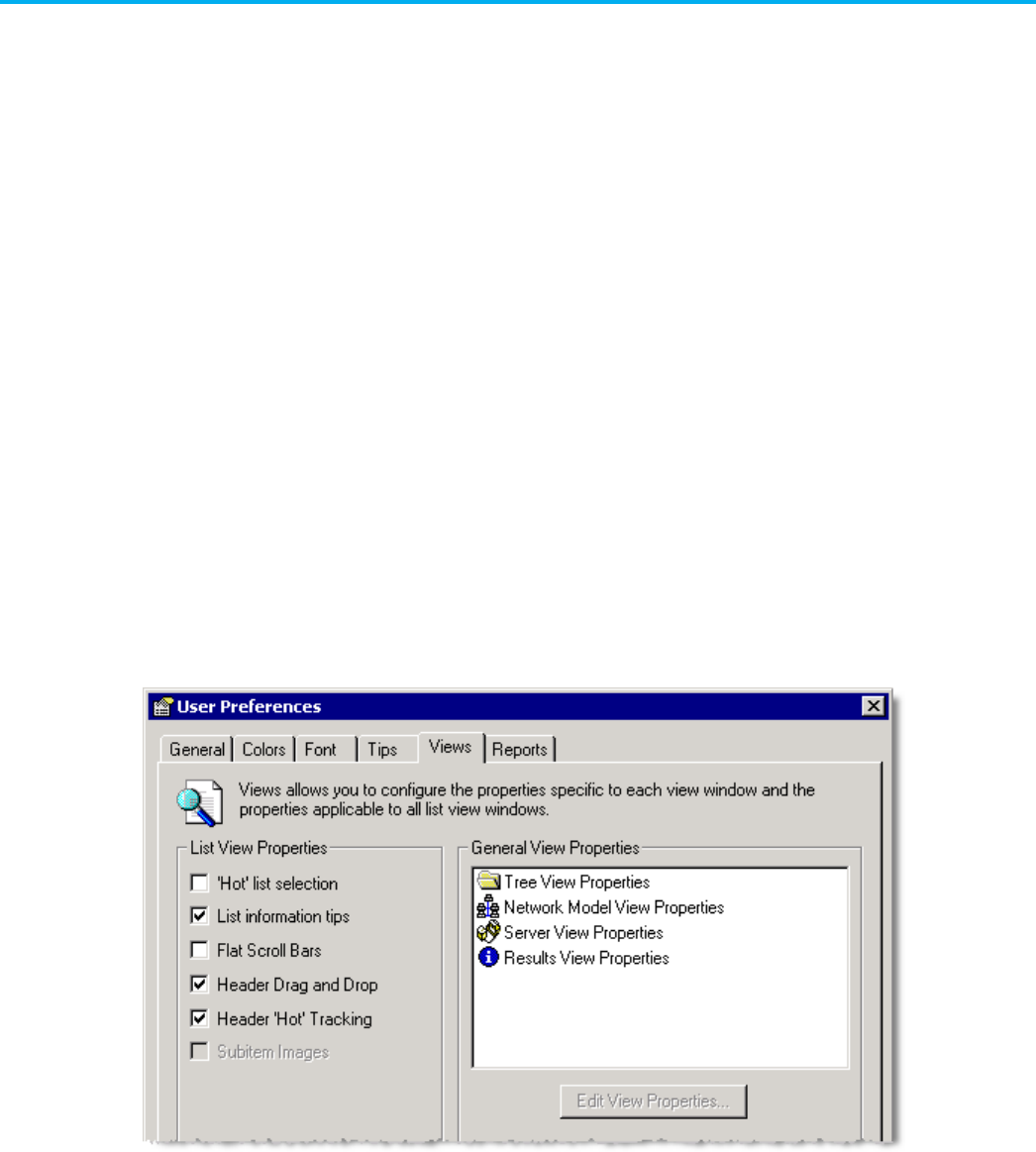

User Preferences dialog box .................................................................... 162

User Preferences dialog box - General tab ....................................... 163

Edit colors ..................................................................................... 164

Edit the application font ............................................................. 164

Edit information tips ................................................................... 164

User Preferences dialog box - Views tab .......................................... 165

List View properties ..................................................................... 165

User Preferences dialog box - Reports tab ....................................... 166

Set report preferences ................................................................. 167

Change margins ........................................................................... 167

Set the report fonts and colors .................................................... 168

Column and row preferences in reports .................................... 170

Report printing formats ...........................................................................171

Preview reports .................................................................................. 172

Print reports ....................................................................................... 172

Print a range of reports ..................................................................... 173

Chapter 14

Abnormal FactoryTalk Batch termination .............................................. 175

Copied log file filename ...................................................................... 175

Abnormal termination batch record entries .................................... 176

Tag verification log information ............................................................. 177

Network Editor

Server

Table of Contents

10 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

Tag verification log file ...................................................................... 177

Windows Event log tag verification events ...................................... 178

FactoryTalk Batch performance chart .................................................... 178

Open the FactoryTalk Batch performance chart ............................. 179

Chapter 15

Create a custom BatchIDCreate.dll ......................................................... 181

Change the BatchIDCreate.dll registration ........................................... 182

Chapter 16

New server user account requirements ................................................. 183

Configure your FactoryTalk Batch system with the new server user

account ..................................................................................................... 183

Server account password change locations ..................................... 184

Change the server user account for the FactoryTalk Batch Server

service ................................................................................................. 184

Change the server user account in FactoryTalk Batch COM+

applications ........................................................................................ 185

Change the server user account in My Computer properties ......... 186

Chapter 17

Batch identification

Change the FactoryTalk Batch

Server user account

General troubleshooting errors

Index

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 11

Preface

This manual provides administrator instructions for the FactoryTalk Batch

components. It is one of a set of related manuals that describe installing,

programming, and operating the FactoryTalk Batch system.

To review FactoryTalk Batch release notes and latest information regarding

product compatibility refer to the

Product Compatibility and Download

Center (PCDC).

The information in this document is presented in an order that should

minimize the effort required for the configuration and administration of a

FactoryTalk Batch system.

The following subjects are included:

• Configuring Regional Settings, Communications, Security, Electronic

Signatures, and Batch Auditing

• Using the FactoryTalk Batch Service Manager, Windows Event Log,

Phase Simulator, and Server

• Configuring Batch IDs and the Batch Server user account.

• General troubleshooting

See also

FactoryTalk Batch communications on page 17

FactoryTalk Batch security on page 19

The FactoryTalk Batch Server on page 73

Batch identification on page 181

Rockwell Automation publishes legal notices, such as privacy policies, license

agreements, trademark disclosures, and other terms and conditions on the

Legal Notices

page of the Rockwell Automation website.

Software and Cloud Services Agreement

Review and accept the Rockwell Automation Software and Cloud Services

Agreement here

.

Open Source Software Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open-source licenses.

You can view a full list of all open-source software used in this product and

their corresponding licenses by opening the oss_license.txt file located your

About this manual

Document organization

Legal Notices

Preface

12 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

product's OPENSOURCE folder on your hard drive. This file is divided into

these sections:

• Components

Includes the name of the open-source component, its version number,

and the type of license.

• Copyright Text

Includes the name of the open-source component, its version number,

and the copyright declaration.

• Licenses

Includes the name of the license, the list of open-source components

citing the license, and the terms of the license.

The default location of this file is:

C:\Program Files (x86)\Rockwell Software\Batch\Batch View HMI

Controls\Release Notes\OPENSOURCE\oss_licenses.txt

You may obtain Corresponding Source code for open-source packages

included in this product from their respective project web site(s).

Alternatively, you may obtain complete Corresponding Source code by

contacting Rockwell Automation via the Contact form on the Rockwell

Automation website:

http://www.rockwellautomation.com/global/about-us/contact/contact.page

.

Please include "Open Source" as part of the request text.

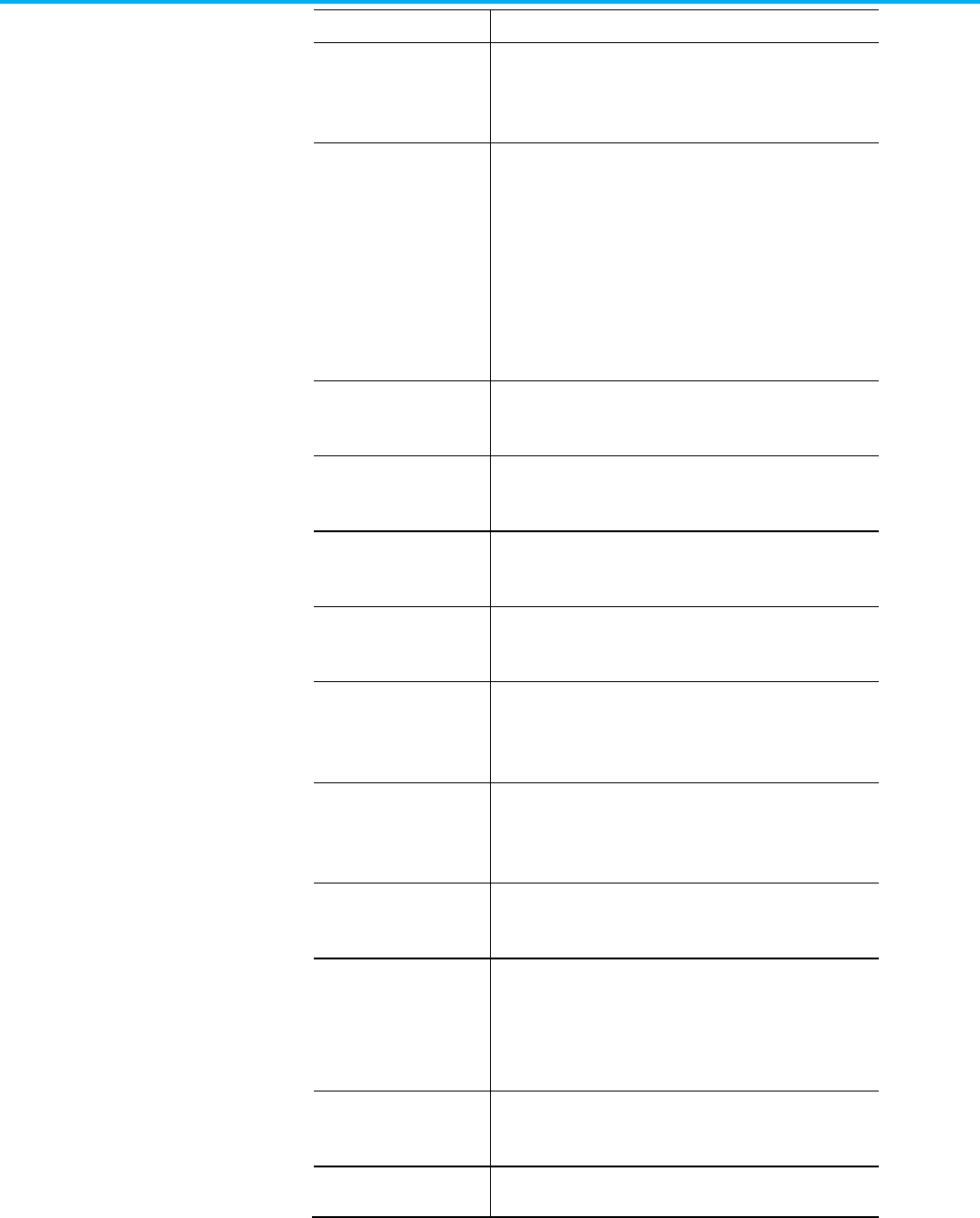

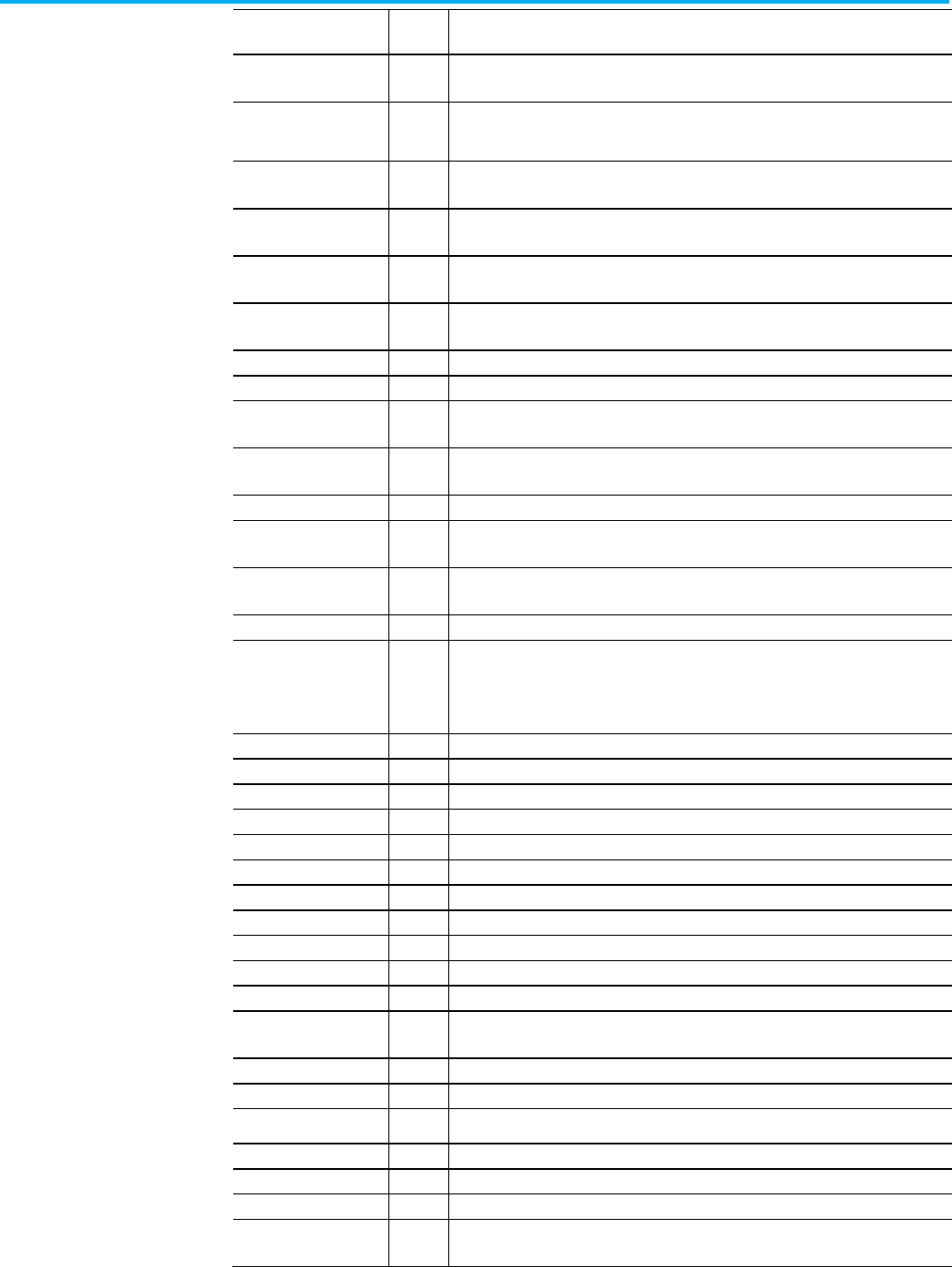

This table is a comprehensive documentation list for the FactoryTalk® Batch

products from Rockwell Automation.

Installation, Quick Start, and Getting Results Guides

Resource

Description

FactoryTalk Batch Components Installation and

Upgrade Guide

(BATCH-IN002)

Provides information and procedures for FactoryTalk Batch system installation.

Includes information for FactoryTalk Batch Material Manager, FactoryTalk Event

Archiver, and associated FactoryTalk Batch Client and Server components.

FactoryTalk Batch View Quick Start Guide

(FTBVS-QS001)

Provides information about using FactoryTalk Batch View to create, view, and

command control recipes, acknowledge prompts and signatures, view equipment

phases and diagnostic information, and view profile information.

FactoryTalk Batch View HMI Controls Quick Start

Guide

(BATCH-QS001D)

Provides a general overview of FactoryTalk Batch View HMI Controls.

FactoryTalk Batch eProcedure® Getting Results

Guide

(BWEPRO-GR011)

Explains the basics of FactoryTalk Batch eProcedure.

FactoryTalk Batch Getting Results Guide

(BATCH-GR011)

Introduces the basics of automated batch manufacturing and the FactoryTalk Batch

product components.

Additional resources

Preface

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 13

Resource

Description

FactoryTalk Batch Material Manager Getting Results

Guide

(BWMTR-GR011)

Introduces the basics of FactoryTalk Batch Material Manager.

User Guides

Resource

Description

FactoryTalk Batch Material Editor User Guide

(BWMTR-UM001)

Provides access to information and procedural instructions required to configure

materials and the containers to hold them. The material data is stored in the material

database, which is used to create material-based recipes. This information is

intended as a reference for formulators.

FactoryTalk Batch Equipment Editor User Guide

(BATCH-UM004)

Provides information on creating and maintaining an equipment database (area

model). The area model is available to all other FactoryTalk Batch programs, including

the Recipe Editor, Batch View, and Phase Simulator.

FactoryTalk Batch PhaseManager™ User Guide

(BATCHX-UM011)

Describes the integration of the FactoryTalk Batch software with the Studio 5000

Logix Designer® application and the Logix 5000™ family of controllers.

The integration simplifies the configuration and maintenance of the FactoryTalk

Batch automation system, provides better communication between the FactoryTalk

Batch Server and the Logix 5000 controller, and significantly reduces the

programming effort required to develop the phase logic code that resides in your

Logix 5000 controller.

FactoryTalk Batch Recipe Editor User Guide

(BATCH-UM006)

Provides instructions on using FactoryTalk Batch Recipe Editor to create and

configure master recipes for use in batch automation. The interface is based on IEC

61131-3 sequential function charts to organize recipes graphically into procedures, unit

procedures, operations, and phases. Build recipes using either the SFC format or a

table-based format.

FactoryTalk Batch View HMI Controls User Manual

(FTBVS-UM003)

Provides details about using FactoryTalk Batch View HMI Controls to monitor and

interact with the production process within a FactoryTalk View SE Display Client.

FactoryTalk Batch View User Manual

(FTBVS-UM002)

Provides information and procedural instructions for using FactoryTalk Batch View in

a modern and intuitive portal into a comprehensive batching solution for effective

operations, leveraging its own web server using HTML5 technology to provide

connectivity into a FactoryTalk Batch Server.

FactoryTalk Event Archiver User Guide

(BATCH-UM012)

Provides information and instructions specific to the FactoryTalk Event Archiver.

Intended for use by system administrators and production supervisors.

Administrator Guides

Resource

Description

FactoryTalk Batch Administrator Guide

(BATCH-UM003)

Provides instructions for configuring security and services, and implementation and

use of components not typically accessed or used by batch operators, such as the

FactoryTalk Batch Server.

FactoryTalk Batch eProcedure Administrator Guide

(BWEPRO-UM011)

Provides procedures specific to FactoryTalk Batch eProcedure, such as implementing

security.

Included are instructions for tasks specific to FactoryTalk Batch, such as configuring

security and services to support FactoryTalk Batch eProcedure. Provides instructions

on the implementation and use of components not typically accessed or used by

batch operators, such as the FactoryTalk Batch Server.

Preface

14 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

Resource

Description

FactoryTalk Batch Material Manager Administrator

Guide

(BWEPRO-UM011)

Provides information and instructions specific to FactoryTalk Batch Material Manager.

Intended for use by system administrators and database administrators.

Reference Guides

Resource

Description

FactoryTalk Batch Material Server API Reference

Manual

(BWMTR-RM001)

Provides access to information regarding the interface between the FactoryTalk Batch

Material Server and the FactoryTalk Batch Material Editor and FactoryTalk Batch. It is

intended to be used as a reference information by custom interface developers.

FactoryTalk Batch PCD Programming Reference

Manual

(BATCH-RM004)

Provides information and instructions about the FactoryTalk Batch PCD interface

design. It is intended to be used as a reference guide for PCD programmers.

FactoryTalk Batch Server API Reference Manual

(BATCH-RM003)

Provides information regarding the interface between the FactoryTalk Batch Server

and FactoryTalk Batch View — the Server Application Programming Interface (API). It is

intended to be used as a reference guide by custom interface developers.

FactoryTalk Batch System Files Reference Manual

(BATCH-RM005)

Provides the technical information for configuration and maintenance of a

FactoryTalk Batch system. It can be used as a reference information for

implementation engineers and system administrators.

FactoryTalk Batch eProcedure Instruction File

Design Reference Manual

(BWEPRO-RM001)

Includes information about the building of manual nstruction files for manual phases

in the equipment database This information is intended to be used as a reference by

instruction file authors.

View or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact your local Allen-Bradley® distributor or

sales representative.

Rockwell Automation recognizes that some of the terms that are currently

used in our industry and in this publication are not in alignment with the

movement toward inclusive language in technology. We are proactively

collaborating with industry peers to find alternatives to such terms and

making changes to our products and content. Please excuse the use of such

terms in our content while we implement these changes.

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 15

Chapter 1

FactoryTalk Batch components

This guide contains instructions for tasks specific to FactoryTalk® Batch

Batch, such as configuring security and services. Instructions are also

provided on the implementation and use of components not normally

accessed or used by batch operators, such as the FactoryTalk Batch Server,

Simulator, and performance chart.

See also

FactoryTalk Batch regional settings on page 15

FactoryTalk Batch communications on page 17

FactoryTalk Batch security on page 19

FactoryTalk Batch electronic signatures on page 37

FactoryTalk Batch audit trail on page 51

FactoryTalk Batch components are supported in U.S. English only. Install the

English language version of the operating system used with FactoryTalk

Batch components to ensure proper operation of FactoryTalk Batch,

FactoryTalk eProcedure, or FactoryTalk Batch Material Manager.

IMPORTANT

Modifying regional settings is not supported.

See also

FactoryTalk Batch security on page 19

FactoryTalk Batch communications on page 17

FactoryTalk Batch regional

settings

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 17

Chapter 2

FactoryTalk Batch communications

The FactoryTalk Batch Server uses the Component Object Model (COM) to

access data from project directories and to communicate with other programs

such as FactoryTalk Batch View, and data servers. All project directories

accessed by the FactoryTalk Batch Server must be shared, and the server user

account must have permission to access that shared directory.

See also

Create a shared directory on page 17

Use Open Platform Communications (OPC) on page 17

A shared directory allows computers on the network to read from and write to

a common recipe, area model, or data file. The FactoryTalk Batch installation

creates a shared directory named BATCHCTL where the FactoryTalk Batch

software is installed (the default is C:\Program Files (x86)\Rockwell

Software\Batch). If you installed your project files in a different directory,

configure that directory as a shared directory. To configure a shared directory,

administrative privileges are required.

To create a shared directory

1. Navigate to the project file directory, then right-click the folder, and

select the sharing option.

2. Use the File Sharing dialog box to add each user or user group name

that requires access to the project file directory.

3. Repeat for each user or user group, including the user accounts used

by the FactoryTalk Batch Server and FactoryTalk Event Archiver.

4. Select Share.

See also

Use Open Platform Communications (OPC) on page 17

The FactoryTalk Batch Server supports the use of the Open Platform

Communications (OPC) protocol. OPC provides a defined set of COM

interfaces for data access functions.

The OPC communications protocol is used by the FactoryTalk Batch Server to

communicate with process-connected devices via a data server and PC-Based

Create a shared directory

Use Open Platform

Communications (OPC)

Chapter 2 FactoryTalk Batch communications

18 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

phases. COM is used to communicate with other high-level applications such

as FactoryTalk Batch Material Manager.

See also

OPC group support on page 18

Within the OPC protocol, data is accessed through collections of data items

referred to as groups. Different data servers have varying levels of OPC

support, including maximum numbers of groups, maximum numbers of

items per group and performance issues, and so on. Because of this,

FactoryTalk Batch support of OPC is flexible in order to achieve successful

communication with as many different data servers as possible. To achieve

this, the FactoryTalk Batch Server is flexible in its definition of Groups, and

allows for different OPC grouping configurations to communicate with the

data server(s).

The manner in which the FactoryTalk Batch Server organizes the area model

tags into groups is defined by data server definition files (DSDF). These files

are located in the Batch\Dataservers directory. FactoryTalk Batch comes with

a predefined set of DSDF files. If you need to communicate with a data server

for which there is no predefined DSDF file, contact Rockwell Automation

Application Support.

See also

Use Open Platform Communications (OPC) on page 17

OPC group support

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 19

Chapter 3

FactoryTalk Batch security

The following information explains administering security for the FactoryTalk

Batch Server using Windows security and implementing FactoryTalk Security

for the FactoryTalk Batch Client components. For information on the

administration of your FactoryTalk Security system as a whole, see

FactoryTalk Help.

To open FactoryTalk Help, select Start > Rockwell Software > FactoryTalk

Help.

To help meet secure system design requirements, review these publications:

• Configure System Security Features User Manual

(publication

SECURE-UM001)

• System Security Design Guidelines Reference Manual (publication

SECURE-RM001)

• Con

verged Plantwide Ethernet (CPwE) Design and Implementation

Guide (publication ENET-TD001)

To learn about implementing CIP Security, see CIP Security with

Rockwell Automation Products (publication SECURE-AT001).See also

FactoryTalk Batch Server user account configuration requirements on

page 19

FactoryTalk Batch system configuration on page 20

FactoryTalk Security for the Batch Clients on page 25

FactoryTalk Batch default policy settings on page 31

Create a Windows user account for the FactoryTalk Batch Server prior to

installing FactoryTalk Batch applications. When installing FactoryTalk Batch

and FactoryTalk eProcedure applications, you are prompted to enter this user

account.

When creating the server user account, the following configuration

requirements must be met.

• The password must be configured to never expire.

If the password expired, the batch server service would fail to log on.

• The server user account must never be disabled or deleted.

If this account is ever disabled or deleted, the batch server service

would fail to log on.

FactoryTalk Batch Server

user account configuration

requirements

Chapter 3 FactoryTalk Batch security

20 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

• The domain user account must have a unique name.

If the server user account is a domain account, remove any local user

accounts with the same name.

• The Server user account or user group must exist on all workgroup

computers.

If you are using a local account and expect that account to have access

to resources on other computers in a workgroup environment, you

must create accounts with the same name and password on each

computer in the workgroup.

See also

FactoryTalk Batch system configuration on page 20

FactoryTalk Batch security on page 19

The FactoryTalk Batch components installation program configures the local

computer with the necessary COM Security settings to allow remote

communication between the FactoryTalk Batch Server and client

applications.

The configuration of the local computer during installation depends on

whether you are installing a server or client application, a FactoryTalk Batch

or eProcedure application and whether the Windows Firewall is enabled or

disabled.

See also

System-wide COM security limit settings on page 20

FactoryTalk Batch Server install configuration on page 21

FactoryTalk Batch Windows Firewall exceptions on page 21

Add the Batch COM service on page 22

To support DCOM client-server communication, configure the local

computer’s COM Security Limits with these access, launch, and activation

permissions.

Access Permissions

Security Limits for ANONYMOUS LOGON:

• Local Access Permissions

• Remote Access Permissions

FactoryTalk Batch system

configuration

System-wide COM security

limit settings

Chapter 3 FactoryTalk Batch security

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 21

Launch and Activation Permissions

Security Limits for ANONYMOUS LOGON:

• Local Launch Permissions

• Local Activation Permissions

• Remote Activation Permissions

See also

FactoryTalk Batch Server install configuration on page 21

FactoryTalk Batch Windows Firewall exceptions on page 21

Add the Batch COM service on page 22

FactoryTalk Batch system configuration on page 20

The installation of the FactoryTalk Batch Server creates the Windows user

group batchsvr_group on the FactoryTalk Batch Server. This group is

automatically assigned all the user rights and default access permissions

required for the FactoryTalk Batch Server to function correctly.

The installation adds the FactoryTalk Batch Server user account to the

following:

• Administrators group

• batchsvr_group

• MasterRecipeAuthor

• MasterRecipeViewer

• Batch COM+ Application

• FactoryTalk Batch Server service

• FactoryTalk Event Archiver service

• FactoryTalk eProcedure Server service (eProcedure Server installation)

The services for the FactoryTalk Batch Server, FactoryTalk Event Archiver,

FactoryTalk eProcedure Server, and the Batch COM+ Application require

identical user accounts to support the FactoryTalk Batch Server functionality.

See also

FactoryTalk Batch system configuration on page 20

FactoryTalk Batch Windows Firewall exceptions on page 21

Add the Batch COM service on page 22

If the Windows Firewall is enabled when you install FactoryTalk Batch or

FactoryTalk eProcedure applications, the installation program adds the

following exceptions to the local computer:

Windows Firewall Exceptions

FactoryTalk Batch Server

install configuration

FactoryTalk Batch Windows

Firewall exceptions

Chapter 3 FactoryTalk Batch security

22 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

•

batchsvr.exe (Batch server installs) •

NmspHost.exe

• CodeMeter Runtime Server

• OPCEnum.exe

• CodeMeterFWEx1 • Port 1433 TCP (SQL Server installs)

•

DaClient.exe •

Port 137 NetBIOS Name Service

•

EventClientMultiplexer.exe •

Port 135 TCP

•

EventServer.exe •

Port 80 TCP

• Flexsvr.exe

• RDcyHost.exe

• FTCounterMonitor.exe • RnaDiagnosticsSrv.exe

• FTSPVStudio.exe

• RnaDiagReceiver.exe

• FTSysDiagSvcHost.exe

• RnaDirServer.exe

• iexplore.exe • RsvcHost.exe

•

Imgrd.exe •

VStudio.exe

If the Windows Firewall is enabled, and not externally controlled, the

Windows Firewall Configuration Utility runs automatically during

installation. If this utility does not run automatically, manually run it on each

computer in your FactoryTalk Batch system after installing servers or clients.

To manually run the FactoryTalk Windows Firewall Configuration Utility,

select Start > Rockwell Software > Windows Firewall Configuration Utility.

See also

FactoryTalk Batch system configuration on page 20

System-wide COM security limit settings on page 20

FactoryTalk Batch Server install configuration on page 21

Add the Batch COM service on page 22

To add the COM service, run the BatchIDCreationCOMPlusInstall script and

then add the server user account to the FactoryTalk Batch Server service,

FactoryTalk Event Archiver service, and the Batch COM+ Application. If

FactoryTalk eProcedure is part of your system, add the server user account to

the eProcedure Server service.

To add the Batch COM service

1. In Windows Explorer, expand Program Files x86 > Rockwell Software

> Batch > Scripts.

2. Double-click BatchIDCreationCOMPlusInstall.vbs to add the

FactoryTalk Batch COM service to the computer.

3. Select Start > Windows Administrative Tools > Component Services >

Computers > My Computer > COM+ Applications.

4. Right-click Batch > Properties.

5. Select the Identity tab, select This user, and enter the user name and

password for the FactoryTalk Batch Server.

6. Select OK and then close Component Services.

Add the Batch COM service

Chapter 3 FactoryTalk Batch security

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 23

7. Select Start > Windows Administrative Tools > Services.

8. Right-click FactoryTalk Batch Server > Properties.

9. Select the Log On tab and then select This Account.

10. Enter the user account name and password for the server.

11. Select OK.

• Add the server user account to FactoryTalk Event Archiver service if

you are using FactoryTalk Event Archiver in incremental mode.

• Add the server user account to the eProcedure Server service if

eProcedure is part of your FactoryTalk Batch system.

12. Close Services.

13. Restart the computer.

See also

FactoryTalk Batch Server install configuration on page 21

FactoryTalk Batch Windows Firewall exceptions on page 21

FactoryTalk Batch system configuration on page 20

Limit log file and event journal (.evt or .evtj) access to prevent data from being

lost. Setting security on the folders or files is one suggested method. Set the

security according to company requirements.

Use Notepad to open log files. If a log file is opened with a program other than

Notepad, the FactoryTalk Batch Server may not run due to an access error.

IMPORTANT

FactoryTalk Batch Server continues writing information to log files and event journals

(

.evt

or

.evtj

) even when they are open. If a file is opened and then saved, data that may

have been written to the event journal or log file while the file is open is lost.

To set security on folders or files

1. In Windows Explorer, locate the folder or file.

2. Right-click the folder or file, and then select Properties.

3. Select the Security tab, select Edit, and then select Add.

4. From the Select Users, Computers, Service Accounts, or Groups dialog

box, select Advanced and then select Find Now.

5. Select a user or group from the Search results list, and then select OK.

6. Repeat for each user or group that requires access to the folder or file.

Be sure to add the FactoryTalk Batch Server user account and then configure the account with

Full

Control

permissions.

7. Select OK to return to the Properties dialog box.

8. From the Group or user name list, select a user or group, and then

select the permissions in the Permissions area. Repeat for each user or

group.

9. Select OK.

Set security on folders or

files

Chapter 3 FactoryTalk Batch security

24 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

See also

FactoryTalk Batch Server user account configuration requirements on

page 19

Set security on folders and files to limit log file and event journal (.evt or .evtj)

access.

To add users and user groups:

1. In Windows Explorer, locate the folder or file.

2. Right-click the folder or file, and then select Properties.

3. Select the Security tab, select Edit, and then select Add.

4. From the Select Users, Computers, Service Accounts, or Groups dialog

box, select Advanced and then click Find Now.

5. Select a user or group from the Search results list, and then select OK.

6. Repeat for each user or group that requires access to the folder or file.

Tip: Be sure to add the FactoryTalk Batch Server user account and then configure the

account with Full Control permissions.

7. Select OK to return to the Properties dialog box.

8. From the Group or user name list, select a user or group, and then

select the permissions in the Permissions area. Repeat for each user or

group.

9. Select OK.

See also

Set security on folders or files on page 23

Change the permissions on the BATCHCTL share to tighten security by

removing the Everyone group and adding a new group that contains all the

Windows users that need to access the share.

IMPORTANT

This new group allows applications to access the BATCHCTL share while locking out

non-domain users.

Include these user types in the group:

• The FactoryTalk Batch Server and FactoryTalk Event Archiver user.

• Windows users logged in when the FactoryTalk Batch Equipment

Editor, FactoryTalk Batch Recipe Editor and FactoryTalk Batch View

are launched.

To change permissions on the BATCHCTL share

1. In Windows Explorer, locate the Batch folder. The default location is

C:\Program Files (x86)\Rockwell Software\Batch.

2. Right-click the Batch folder, and then select Properties.

Add users and user groups

Change permissions on the

BATCHCTL share

Chapter 3 FactoryTalk Batch security

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 25

3. Select the Security tab and do the following:

a. Select Edit, select the Everyone group, and then select Remove.

b. After removing the Everyone group, select Add.

4. From the Select Users, Computers, Service Accounts, or Groups dialog

box, select Advanced and then click Find Now.

5. Select a group from the Search results list, and then select OK.

6. Select OK to return to the Properties dialog box.

7. From the Group or user name list, select a user or group, and then

select the permissions in the Permissions area. Repeat for each user or

group.

8. Select OK.

Security settings are shared among FactoryTalk enabled products across a

network or on the same computer using FactoryTalk Security in FactoryTalk

Batch View, HMI Controls, FactoryTalk Batch Equipment Editor, and

FactoryTalk Batch Recipe Editor. FactoryTalk Directory is the infrastructure

which contains the policies defined for products and resources.

FactoryTalk Batch product policies are created in both the Local Directory and

the Network Directory when the FactoryTalk Services Platform is installed.

The FactoryTalk Batch product polices are used to restrict access to the

FactoryTalk Batch Client components and their features. For a complete list of

FactoryTalk Batch secured resources and their default product policy settings,

see FactoryTalk Batch default policy settings.

The following information is specific to configuring FactoryTalk Security for

the FactoryTalk Batch Clients. For information on securing your FactoryTalk

system as a whole, see FactoryTalk Help.

To open FactoryTalk Help, click Start > Rockwell Software > FactoryTalk

Help.

The FactoryTalk Services Platform installation process:

• Creates a FactoryTalk Local Directory and a FactoryTalk Network

Directory on the computer. When the install process finishes, both

directories are fully configured and ready for use.

Tip: Security settings in the Network Directory are completely separate from the security

settings in the Local Directory. For example, changes made to the security settings in the

Network Directory do not change security settings in the Local Directory.

• Allows any Windows Administrator user account to log on to either

directory. The installation process automatically adds the local

Windows Administrators group to the FactoryTalk Administrators

group in each FactoryTalk Directory.

• Allows any authenticated Windows user to log on to the FactoryTalk

Local Directory. The installation process automatically adds all

members of the local Windows Authenticated Users group to the

FactoryTalk Local Directory.

FactoryTalk Security for the

Batch Clients

Chapter 3 FactoryTalk Batch security

26 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

• Allows all new user accounts full access permissions. The installation

process automatically sets system policies to allow all new user

accounts added to either directory full access to that directory by

default.

See also

FactoryTalk Batch default policy settings on page 31

Tighten security for FactoryTalk Batch Clients on page 26

Restrict access to specific features of your individual FactoryTalk products.

Only users with access can use secured product features.

For example, when you set up product policies for FactoryTalk Batch, restrict

use of the Abort command to specific users. This prevents automated batch

processes from being unintentionally aborted during run time.

To configure security for multiple features in FactoryTalk, use the Feature

Security for Product Policies dialog box.

To configure security for the FactoryTalk Batch features, refer to the secured

product policies defined for the FactoryTalk Batch Clients.

To tighten security for FactoryTalk Batch Clients:

• Delete the Windows Authenticated Users group from the Local

Directory.

• Create new FactoryTalk user accounts and groups in the FactoryTalk

Directory. Create user accounts or groups to secure the FactoryTalk

Batch Clients.

• Add user accounts and groups created in Windows to the FactoryTalk

Directory. Windows accounts added to the FactoryTalk Directory are

called Windows-linked user accounts and groups.

IMPORTANT

Windows Workgroup User Accounts are not supported in FactoryTalk.

If you use Windows workgroups, you cannot administer user accounts centrally

for FactoryTalk Batch Client applications. FactoryTalk Directory does not allow

multiple user accounts to have the same name and password.

• Remove the All Users group from the FactoryTalk Batch product

policies. The FactoryTalk Services Platform installation process adds

the All Users group to all FactoryTalk product policies.

• Add user accounts and groups to the FactoryTalk Batch product

policies. To secure FactoryTalk Batch resources, add only the necessary

user accounts and groups to the corresponding product policies.

See also

FactoryTalk Batch Client security

Tighten security for

FactoryTalk Batch Clients

Chapter 3 FactoryTalk Batch security

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 27

Security for FactoryTalk Batch Equipment Editor and FactoryTalk Batch

Recipe Editor is implemented using the FactoryTalk Security product policies

defined in the FactoryTalk Network Directory. There are two product policy

options available:

• Access Modes governs access to the editors (only FactoryTalk users can

be granted access). There are two levels of working access to area

models in FactoryTalk Batch Equipment Editor, and recipes in

FactoryTalk Batch Recipe Editor.

• View Only provides full viewing privileges, but no changes can be

saved.

• Full Edit provides full editing privileges.

• Feature Security governs which FactoryTalk users can secure area

models and recipes to the FactoryTalk Network Directory Security

Authority Identifier (SAI).

• The Area Model: Secure policy governs which users can secure an

area model to a particular SAI in FactoryTalk Batch Equipment

Editor.

• The Recipe: Secure policy governs which users can secure a recipe

to a particular SAI in FactoryTalk Batch Recipe Editor.

Additionally, there are other Configuration Options product policies created

in the FactoryTalk Local Directory for the editors.

• To tighten security, remove the All Users group from FactoryTalk

Batch Equipment Editor and FactoryTalk Batch Recipe Editor product

policies in the FactoryTalk Directory.

• FactoryTalk Batch Equipment Editor and FactoryTalk Batch Recipe

Editor support the use of an external security device, such as a retinal

scanner.

• In addition to FactoryTalk Security, configure Windows security on

FactoryTalk Batch Equipment Editor and FactoryTalk Batch Recipe

Editor files and folders in Windows Explorer.

• RDB security can also be configured when using RDB recipes that are

stored in SQL Server.

See also

Configure access mode security on page 28

Configure feature security on page 28

Product policies in the local and network directories on page 31

Modify FactoryTalk Batch Equipment Editor configuration options on

page 29

FactoryTalk Batch

Equipment Editor and

FactoryTalk Batch Recipe

Editor security

Chapter 3 FactoryTalk Batch security

28 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

Configure the two levels of working access to area models in FactoryTalk

Batch Equipment Editor, and recipes in FactoryTalk Batch Recipe Editor.

To configure the access mode security:

1. Open the FactoryTalk Administration Console and log on to the

appropriate FactoryTalk Directory.

2. Expand System > Policies > Product Policies > Batch > Equipment

Editor (or Recipe Editor).

3. Right-click Access Modes and then select Properties.

4. Select the policy setting you want to configure and then click the

browse button.

5. In the Configure Securable Action dialog box:

• Select a user or group and then click Remove.

• Allow or deny a user or group access to the feature by selecting or

clearing the corresponding check box and then clicking OK.

• Add a user account or user group by clicking Add. This option

displays the Select User and Computer dialog box.

6. In the Select User or Group dialog box:

• Select a user, user group, computer or computer group and then

click OK.

• Click Create New to create and then add a new user, user group or

computer group.

7. Click OK to close the Access Modes Properties dialog box.

8. Restart all FactoryTalk Batch components to update changes made in

the FactoryTalk Directory.

See also

FactoryTalk Batch Equipment Editor and FactoryTalk Batch Recipe

Editor security on page 27

Configure feature security on page 28

Modify FactoryTalk Batch Equipment Editor configuration options on

page 29

Configure which users can secure area models and recipes to the FactoryTalk

Network Directory Security Authority Identifier (SAI).

To configure feature security:

1. Open the FactoryTalk Administration Console and log on to the

appropriate FactoryTalk Network Directory.

Configure access mode

security

Configure feature security

Chapter 3 FactoryTalk Batch security

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 29

2. Expand System > Policies > Product Policies > Batch > Equipment

Editor (or Recipe Editor).

3. Right-click Feature Security and then select Properties. The Feature

Security Properties dialog box opens.

4. Select Area Model: Secure and then click browse ( ). For FactoryTalk

Batch Recipe Editor, the policy is Recipe: Secure.

5. In the Configure Securable Action dialog box you can:

• Click Add to add a user account or user group using the Select User

and Computer dialog box:

• Select a user, user group, computer or computer group and then

click OK.

• Click Create New to create and then add a new user, user group,

or computer group.

• Allow or deny a user or group access to the feature by selecting or

clearing the corresponding check box and then clicking OK.

• Select a user or group and then click Remove.

6. Click OK to close the Feature Security Properties dialog box.

Tip: Restart all FactoryTalk Batch components to update changes made in the FactoryTalk

Network Directory.

See also

FactoryTalk Batch Equipment Editor and FactoryTalk Batch Recipe

Editor security on page 27

Configure access mode security on page 28

Modify FactoryTalk Batch Equipment Editor configuration options on

page 29

Modify the configuration options in product policies created in the

FactoryTalk Local Directory for the editors.

The following example is specific to FactoryTalk Batch Equipment Editor.

FactoryTalk Batch Recipe Editor configuration options are configured

similarly.

To modify FactoryTalk Batch Equipment Editor configuration

options:

1. Open the FactoryTalk Administration Console and then log on to the

FactoryTalk Local Directory.

2. Expand System > Policies > Product Policies > Batch > Equipment

Editor > Configuration.

3. Right-click Options and then select Properties.

Modify FactoryTalk Batch

Equipment Editor

configuration options

Chapter 3 FactoryTalk Batch security

30 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

4. From the Options Properties dialog box, configure the policy settings

and then click OK.

Tip: Restart all FactoryTalk Batch components to update changes made in the FactoryTalk

Directory.

See also

Configure access mode security on page 28

FactoryTalk Batch Equipment Editor and FactoryTalk Batch Recipe

Editor security on page 27

Configure feature security on page 28

Product policies in the local and network directories on page 31

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 31

Chapter 4

FactoryTalk Batch default policy settings

When the FactoryTalk Services Platform is installed, FactoryTalk Security

product policies are created in the FactoryTalk Directory for FactoryTalk

Batch View clients.

The product policies for FactoryTalk Batch Clients are created in both the

Local and Network Directories, except for the Configuration Options which

are only created in the Local Directory.

See also

Product policies in the local and network directories on page 31

The FactoryTalk Batch components have product policies that can be secured

with FactoryTalk Security.

Policies are applied to secured objects that can then be configured to require

user validation prior to execution. By default, all users have access to

FactoryTalk Batch components. To tighten security, remove or restrict the All

Users group and then add the necessary user accounts to the policy setting. To

require user validation for a command, set the associated Confirmation policy

setting to True. Additionally, you can restrict access to resources based on

where a user is physically located, such as a computer used to perform actions.

For details, see FactoryTalk Help.

The System\Policies\Product Policies\Batch\Feature Security setting is used

to control whether users can make changes to the area model while the batch

server is running.

Security Objects

Product Policy Descriptions

Configure Runtime Area Model Deployment

Allow access to Runtime Area Model Deployment. With this

permission users can make changes to the area model and

deploy the changes while the area model is online with the

batch server.

By default, only members of the Administrator group have

access.

The product policy configurations are created in the FactoryTalk Local and

Network Directories for FactoryTalk Batch. FactoryTalk Batch product policy

is located in FactoryTalk Directory > System > Policies > Product Policies >

Batch.

Product policies in the local

and network directories

Chapter 4 FactoryTalk Batch default policy settings

32 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

BatchCampaign policies are provided for backwards compatibility with

Rockwell Automation product Batch Campaign Manager. Batch Campaign

Manager is no longer licensed or supported by Rockwell Automation and has

been released to the market as open source. The source code for Batch

Campaign Manager can be downloaded from the

Rockwell Automation

Sample Code Library.

BatchView product policies determine how clients interact with the different

FactoryTalk Batch components. Configure policies in the following areas:

• Batch View Server (modern clients)

• Commands (legacy clients)

• Phase Commands (legacy clients)

• View (legacy clients)

The product policy configurations can be created in either the FactoryTalk

Local and Network Directories. FactoryTalk Batch product policy is located in

FactoryTalk Directory > System > Policies > Product Policies > Batch >

BatchView.

Batch View Server

The Batch View Server security policy settings enable the modern FactoryTalk

Batch View client and FactoryTalk Batch View HMI User Controls within a

FactoryTalk View SE Display Client to control aspects of the Batch Server.

Confirmation Authorization is enabled or disabled for all of these settings as a

whole instead of for each setting individually.

• The Command Batch section contains settings related to the batch

process.

• The Command Equipment section contains settings related to the

resources and equipment.

• The Command Prompts section contains settings related to operator

prompts.

Security Objects

Product Policy Descriptions

Command Batch

•

Abort

•

Abort a batch

• Add Batch

• Add a batch

• Bind

• Bind a batch

•

Change Active Step

• Enables or disables the Active Step Change toggle.

•

Clear Failure

•

Clears all failures and system-generated messages

•

Comment

•

All the Operator to enter a comment in the event journal.

•

Disconnect

•

Disconnect an equipment module

•

Force Transition

•

Force transition to next step

•

Hold

•

Hold a batch

• Material Server Reconnect

• Reconnect to the Material Server

• Auto Mode

• Run the batch in automatic mode

• Manual Mode

• Run the batch in manual mode

BatchCampaign policy

settings

BatchView policy settings

Chapter 4 FactoryTalk Batch default policy settings

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 33

Security Objects

Product Policy Descriptions

• Semi Auto Mode

• Run the batch in semi-automatic mode

•

Override Expression

• Allow the Operator to override the expression by

assigning a new value.

• Override Expression Clear

• Allow the Operator to clear the assigned override value.

•

Remove

•

Remove a batch

•

Restart

•

Restart a batch

•

Resume

•

Resume a batch

•

Change Parameter

•

Change a parameter value

•

Start

•

Start a batch

• Stop

• Stop a batch

• Tag Verify

• Start the tag verification process

• Timer Complete

• Forces a timer step to complete

•

Timer Reset

• Resets the ELAPSED_TIME in a Timer step to 0 (if the

Timer step is configured as a COUNT_DOWN timer the

REMAINING_TIME will be reset to the setpoint value).

Command Equipment

•

Abort

• Abort an equipment phase

•

Acquire

•

Acquire ownership of the equipment resource

•

Clear Failure

•

Clear a failure on the equipment module

•

Container Data

• Configure the set of containers from which this

equipment module can select material, or into which it

can distribute material, or both.

•

Disconnect

•

Disconnect from the equipment resource

• Hold

• Temporarily stops execution of the batch at a step.

•

Auto Mode

• Put the equipment into auto mode giving control of the

running batch to the FactoryTalk Batch Server.

•

Semi Auto Mode

• Put the equipment into semi-auto mode so you can

control the execution of all filter steps in the current

batch.

•

Release

•

Release ownership of the equipment resource

•

ReOrder

• Change the priority order for the equipment resource

• Reset

• Resets the resource to the idle state.

• Restart

• Restarts a batch that is currently on the batch list.

• Resume

• Continues processing on a batch that is paused.

•

Stop

• Performs an orderly termination of a currently running

batch.

• Start

• Starts a batch that is currently on the batch list

Command Prompts

• Acknowledge

• Acknowledges a prompt.

•

Reactivate

• Reactivate past instructions in a phase that is currently

RUNNING that does not have pending, reactivated steps.

•

Sign

• Complete an electronic signature record for the

resource.

• Sign Cancel

• Cancel the electronic signature request for the resource

Confirmation Authorization

•

Disable Confirmation

• When selected, the Batch View Server commands will not

require additional confirmation before being sent from

the client component to the batch server.

Chapter 4 FactoryTalk Batch default policy settings

34 Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023

Commands

These policy settings apply to the legacy FactoryTalk Batch View, eProcedure

client, and ActiveX controls, which are no longer supported.

Phase Commands

These policy settings apply to the legacy FactoryTalk Batch View, eProcedure

client, and ActiveX controls, which are no longer supported.

View

These policy settings apply to the legacy FactoryTalk Batch View, eProcedure

client, and ActiveX controls, which are no longer supported.

Equipment Editor product policy settings are used to control access to the

Equipment Editor and the area model.

The product policy configurations can be created in either the FactoryTalk

Local and Network Directories. FactoryTalk Batch product policy is located in

FactoryTalk Directory > System > Policies > Product Policies > Batch >

Equipment Editor.

Security Objects

Product Policy Descriptions

Recipe Editor — Access Modes

• Full Edit Once logged on, the user can edit and save changes to the

area model.

To tighten security, remove or restrict the

All Users

group

and then add the necessary user accounts.

Default =

All Users

have access.

• ViewOnly Once logged on, the user can view and edit the Area Model

but cannot save changes.

Default =

All Users

have access.

Equipment Editor -- Feature Security

• Area Model: Secure Once logged on, Full Edit users can enable Security

Authority for an area model. The secured area model

contains the same Security Authority Identifier (SAI) as

stored in the FactoryTalk Network Directory. Thereafter,

the area model can only be opened and worked on in

FactoryTalk Batch Equipment Editor under the same SAI.

Attempting to open the area model under another SAI

results in a security error.

Recipe Editor product policy settings are used to control access to the Recipe

Editor and the recipes.

The product policy configurations can be created in either the FactoryTalk

Local and Network Directories. FactoryTalk Batch product policy is located in

FactoryTalk Directory > System > Policies > Product Policies > Batch > Recipe

Editor

Security Objects

Product Policy Descriptions

Equipment Editor policy

settings

Recipe Editor policy

settings

Chapter 4 FactoryTalk Batch default policy settings

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 35

Recipe Editor — Access Modes

• Full Edit Once logged on, the user can edit and save changes to

recipes.

To tighten security, remove or restrict the

All Users

group and then add the necessary user accounts.

Default = All Users have access.

• ViewOnly Once logged on, the user can view recipes, but cannot

make changes or save the recipe with a new name

using the

Save As

function.

Default =

All Users

have access.

Recipe Editor -- Feature Security

• Recipe: Secure Once logged on, Full Edit users can enable Security

Authority for a recipe. The secured recipe contains the

same Security Authority Identifier (SAI) as stored in the

FactoryTalk Network Directory. Thereafter, the recipe

can only be opened and worked on in FactoryTalk

Batch Recipe Editor if the current FactoryTalk Network

Directory has the same SAI. Attempting to open the

recipe under another SAI results in a security error.

Rockwell Automation Publication BATCH-UM003C-EN-D - November 2023 37

Chapter 5

FactoryTalk Batch electronic signatures

FactoryTalk Batch electronic signatures are electronically recorded

representations of a signature and their associated data. Signature data

includes time stamps, security permissions, meanings for signoffs, and

comments. When a signature request is created, an entry is recorded in the