User Manual

Original Instructions

E100 Electronic Overload

Relay

Bulletins 193, 592

2 Rockwell Automation Publication 193-UM013C-EN-P - November 2022

E100 Electronic Overload Relay User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and operation of this equipment before

you install, configure, operate, or maintain this product. Users are required to familiarize themselves with installation and wiring instructions in addition to

requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be carried out by suitably

trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

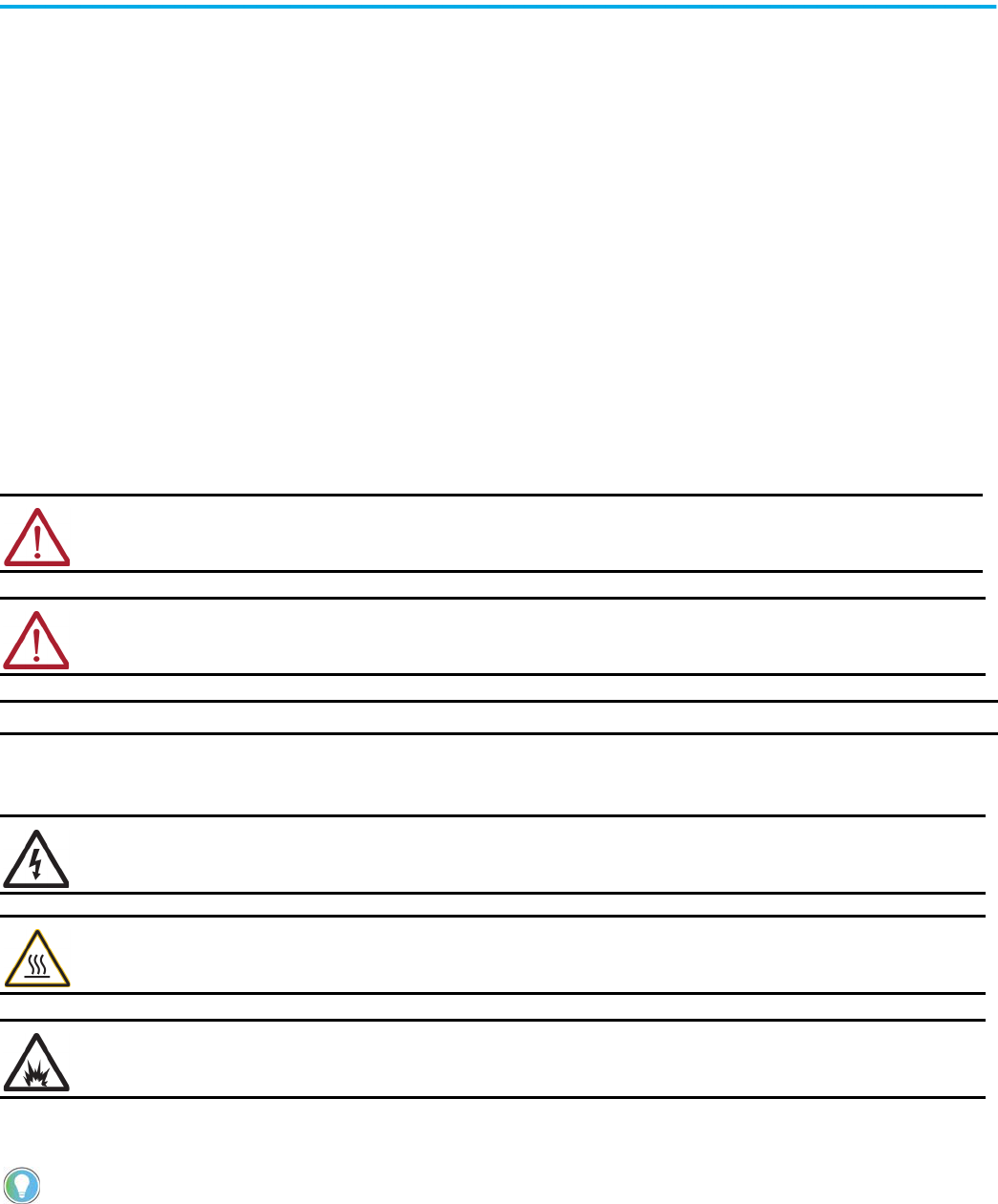

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

These labels may also be on or inside the equipment to provide specific precautions.

The following icon may appear in the text of this document.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Identifies information that is useful and can help to make a process easier to do or easier to understand.

Rockwell Automation Publication 193-UM013C-EN-P - November 2022 3

Table of Contents

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 1

Product Overview Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2

System Operation and

Configuration

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Configure the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Configure Accessory Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 3

Troubleshooting E100 Electronic Overload Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Accessory Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Appendix A

Wiring Diagrams E100 Wiring Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Rockwell Automation Publication 193-UM013C-EN-P - November 2022

Table of Contents

Notes:

Rockwell Automation Publication 193-UM013C-EN-P - November 2022 5

Preface

About This Publication

This manual describes how to install, configure, operate, and troubleshoot the E100™

Electronic Overload Relay.

Summary of Changes This publication contains the following new or updated information. This list includes

substantive updates only and is not intended to reflect all changes.

Terminology Throughout this publication, we also refer to the E100 Electronic Overload Relay as the E100

overload relay and E100 relay. These terms are interchangeable.

Additional Resources These documents contain additional information concerning related products from Rockwell

Automation. You can view or download publications at rok.auto/literature.

Topic Page

Added information for use with Bulletin 100-E contactors throughout

Resource Description

E100 Electronic Overload Relay Specifications, publication 193-TD013 Provides complete specifications for the E100 Electronic Overload Relay.

Bulletin 193 Core Balanced Ground Fault Sensor Application and Installation

Instructions, publication 193-IN047

Provides instruction about how to install and apply 193-CBCT core balanced ground fault

sensors.

E100 Overload Relay Application and Installation Instructions (IEC),

publication 193-IN081

Provides instruction about how to install the E100 Overload Relay onto IEC contactors.

E100 Ground Fault/Jam and Remote Reset Module Application and

Installation, publication 193-IN082

Provides instruction about how to install and apply the ground fault/jam and remote reset

module.

E100 Overload Relay with Pass-thru Wiring Application and Installation

Instructions, publication 193-IN083

Provides instruction about how to install the E100 Overload Relay with the pass-thru wiring

option.

E100 External Current Transformer Overload Relay Application and

Installation Instructions, publication 193-IN084

Provides instruction about how to install the Advanced E100 Overload Relay.

E100 Overload Relay Remote Reset Installation, publication 193-IN085 Provides instruction about how to install and set up the remote reset module.

E100 DIN Rail or Panel Adapter Installation, publication 193-IN086

Provides instruction about how to install the E100 relay onto DIN Rail or the panel adapter.

E100 Remote Indication Display Application and Installation,

publication 193-IN087

Provides instruction about how to install and set up the remote status indication module.

E100 Overload Relay Application and Installation Instructions (NEMA),

publication 592-IN021

Provides instruction about how to install the E100 Overload Relay onto 500 line contactors.

EtherNet/IP Network Devices User Manual, ENET-UM006

Describes how to configure and use EtherNet/IP devices to communicate on the EtherNet/IP

network.

Ethernet Reference Manual, ENET-RM002

Describes basic Ethernet concepts, infrastructure components, and infrastructure features.

System Security Design Guidelines Reference Manual, SECURE-RM001

Provides guidance on how to conduct security assessments, implement Rockwell

Automation products in a secure system, harden the control system, manage user access,

and dispose of equipment.

UL Standards Listing for Industrial Control Products,

publication CMPNTS-SR002

Assists original equipment manufacturers (OEMs) with construction of panels, to help ensure

that they conform to the requirements of Underwriters Laboratories.

American Standards, Configurations, and Ratings: Introduction to

Motor Circuit Design, publication IC-AT001

Provides an overview of American motor circuit design based on methods that are outlined

in the NEC.

Industrial Components Preventive Maintenance, Enclosures, and Contact

Ratings Specifications, publication IC-TD002

Provides a quick reference tool for Allen-Bradley industrial automation controls and

assemblies.

Safety Guidelines for the Application, Installation, and Maintenance of

Solid-state Control, publication SGI-1.1

Designed to harmonize with NEMA Standards Publication No. ICS 1.1-1987 and provides

general guidelines for the application, installation, and maintenance of solid-state control in

the form of individual devices or packaged assemblies incorporating solid-state

components.

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Provides general guidelines for installing a Rockwell Automation industrial system.

Product Certifications website, rok.auto/certifications. Provides declarations of conformity, certificates, and other certification details.

EtherNet/IP Network Devices User Manual, ENET-UM006

Describes how to configure and use EtherNet/IP devices to communicate on the EtherNet/IP

network.

6 Rockwell Automation Publication 193-UM013C-EN-P - November 2022

Notes:

Rockwell Automation Publication 193-UM013C-EN-P - November 2022 7

Chapter 1

Product Overview

This chapter provides an overview of the E100™ Electronic Overload Relay.

Description The E100 Electronic Overload Relay is the newest technology for overload protection, and

supports both single- and three-phase operation in a single component.

The device is available in two versions: a Basic (Cat. No. 193-1EE) and Advanced (Cat. No. 193-

1EF, 592-1EF) version. The Basic offering allows adjustable trip current, manual trip reset, and

limited trip class selection. The Advanced version offers the same adjustable trip current,

manual or automatic trip reset, a larger selection of trip classes, and the ability to add

additional accessory modules.

The E100 relay provides the following benefits:

• Electronic overload detection

• Simple configuration

• Selectable trip class

• Adjustable trip current

• Integration with both IEC and NEMA contactors

• Test and Reset buttons

• Auto/Manual reset selection

• RMS Current sensing (50/60 Hz)

•External current transformers

• Direct and Pass-thru mounting

The advanced version of the E100 relay (193/592-EF only) lets you add the following accessory

modules through the front-mounted communication port. Accessories include:

• Ground Fault/Jam Protection Module

• Remote Indication Display, with or without Reset

• Remote Reset Module

Other accessories for both versions include:

• Remote Reset Solenoid

• Anti-Tamper Shield

•Reset Adapter

• Panel Adapter

8 Rockwell Automation Publication 193-UM013C-EN-P - November 2022

Chapter 1 Product Overview

Notes:

Rockwell Automation Publication 193-UM013C-EN-P - November 2022 9

Chapter 2

System Operation and Configuration

This chapter provides instructions about how to operate and configure an E100™ Electronic

Overload Relay system. It includes instructions about how to set the Trip Current and Trip

Class. This chapter also describes the accessory modules that are available for the Advanced

(193/592-1EF) E100 relay.

Before You Begin Before you configure the E100 relay, you must install it onto a contactor or DIN Rail, or mount it

on a panel. See page 5 for a list of related installation instructions. You can search for and

download literature at rok.auto/literature

.

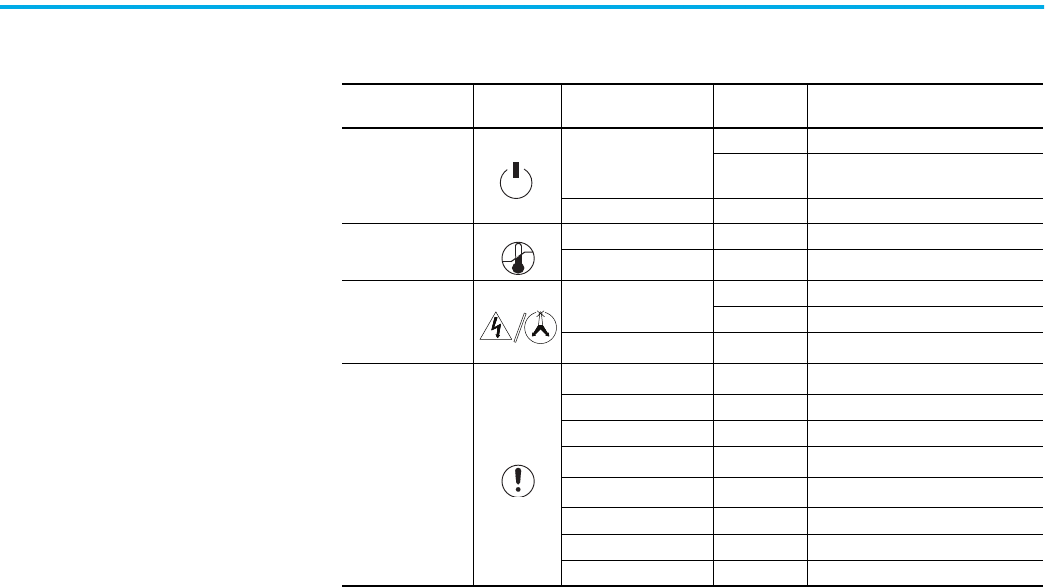

Configure the Device Use the rotary dials on the front of the unit to select the trip class and adjust the trip current.

Figure 1 - E100 Overload Relay Settings

Basic Unit, 193-1EE… Advanced Unit, 193/592-1EF…

Trip Current Selection

(1)

Trip Current

Selection

(1)

Trip Class Selection

(2)

Trip Class/Reset Selection

(2)

Reset

Reset

Push to Stop

Push to Stop

Push to Test

Push to Test

Trip Indicator Window

(3)

Trip Indicator

Window

(3)

Communication Port

Note Number Feature Information

1 Trip Current Selection

To adjust the trip current, turn the dial until the desired current is aligned with the pointer. Trip rating is 120% of dial setting value.

Minimum setting is 0.1 FLA.

2 Trip Class Selection

Use this setting to select the desired trip class. Basic units only support manual reset operations. Manual DIP switch position is

independent of relay function and trip class. On Advanced units, use this setting to select between automatic and manual reset

modes.

3 Trip Indicator Window The red status indicator is visible when the unit has tripped.

10 Rockwell Automation Publication 193-UM013C-EN-P - November 2022

Chapter 2 System Operation and Configuration

Set the Trip Current

When you set the trip current, you must consider the motor service factor and FLA. You can

find this information on the motor nameplate, as shown in Table 1 and Table .

Table 1 - Service Factor/Motor FLA Dial Settings

Service Factor Trip Current Setting

<1.15 0.9 x FLA

≥ 1.15 1 x FLA

Y (Star-Delta) FLA/1.73

Table 2 - Service Factor/Motor FLA Dial Settings

Service Factor Trip Current Setting

Y (Star-Delta) FLA/1.73

Direct-on-line 1 x FLA

Service Factor

FLA

FLA

Rockwell Automation Publication 193-UM013C-EN-P - November 2022 11

Chapter 2 System Operation and Configuration

Configure Accessory

Modules

This section describes how to configure the accessory modules for the Advanced version (193/

592-1EF) of the E100 relay. You must correctly install the accessories before you configure

them. See page 5

for a list of related installation instructions.

Cat. No. 193-1EGJ Universal Protection Expansion Module

The Cat. No. 193-1EGJ Universal Protection module adds ground fault and jam protection to the

Advanced version (193/592-1EF) of the E100 relay. The add-on module lets you select the jam

current level, jam trip delay, and ground fault level.

Figure 2 - Cat. No. 193-1EGJ Universal Protection Expansion Module Settings

Note Number Feature Information

1 Jam Level Selection Set the FLA percentage for Jam Protection. Selectable from 125…600% FLA.

2 Jam Delay Selection Set the time delay for a Jam Trip to occur. Customizable from 0.1…10 s

3

Ground Fault Level

Selection

Set the current level for a Ground Fault Trip to occur. Customizable from

0.02…5 A.

4

Accessory

Diagnostic LED

For more information about the diagnostic LED codes, see page 16

.

Jam Level

(1)

Jam Delay

(2)

Ground Fault Level

(3)

Accessory Diagnostic LED

(4)

12 Rockwell Automation Publication 193-UM013C-EN-P - November 2022

Chapter 2 System Operation and Configuration

Wiring

Figure 3 shows the basic wiring for the 193-1EGJ Module.

Figure 3 - Cat. No. 193-1EGJ Universal Protection Expansion Module Wiring

Cat. No. 193-1ERR Electronic Reset and Indication Display Module

The Cat. No. 193-1ERR Electronic Reset and Indication Display Module lets you use the Cat. No.

193-ERID and 193-ERIDN Remote Indication and Display module with the Advanced version (193/

592-1EF) of the E100 relay.

Figure 4 - Cat. No. 193-1ERR Electronic Reset and Indication Display Module

Note Number Information

1 Terminals R1 and R2 are used with 193-ERID and 193-1ERIDN modules.

2 External power must be user supplied. 24…240V, 47…63 Hz or DC.

3 Reserved for 193-CBCT external ground fault current sensor.

Note Number Feature Information

1 Accessory Diagnostic LED For more information about the diagnostic LED codes, see Chapter 3

.

R1

R2

S1

S2

A1

A2

(1)

(2)

(3)

Accessory Diagnostic LED

(1)

Rockwell Automation Publication 193-UM013C-EN-P - November 2022 13

Chapter 2 System Operation and Configuration

Wiring

Figure 5 shows the basic wiring for the 193-1ERR Module.

Figure 5 - Cat. No. 193-1ERR Electronic Reset and Indication Display Module Wiring

Cat. No. 193-ERID or 193-1ERIDN Remote Indication and Display Module

The remote indication and display modules let you view the status of the E100 relay from the

front of a panel. Cat. No. 193-ERID also features a reset button. The light-emitting diode (LED)

status indicators show the status of the overload relay.

Figure 6 - Cat. No. 193-ERID and 193-1ERIDN Remote Indication and Display Module Features

See page 17 for information about the fault and status codes for the remote indication and

display modules.

Figure 3

and Figure 5 show the basic wiring for the 193-ERID and 193-1ERIDN Modules.

Note Number Information

1 Cat. No. 193-ERID or 193-1ERIDN Remote Indication and Display module.

2 External power must be user supplied. 24…240V, 47…63 Hz or DC.

R2

R1

A1

A2

(1)

(2)

Reset (193-ERID only)

Module Power/Status

Fault Status

Phase Loss

Overload

14 Rockwell Automation Publication 193-UM013C-EN-P - November 2022

Chapter 2 System Operation and Configuration

Notes:

Rockwell Automation Publication 193-UM013C-EN-P - November 2022 15

Chapter 3

Troubleshooting

This chapter helps you troubleshoot the E100™ Electronic Overload Relay by using the

diagnostic LED status indicators. It also guides you through troubleshooting associated

accessory modules.

E100 Electronic Overload

Relay

All E100 relay units include a trip indicator window on the front of the unit labeled “Status”. If

the red indicator is not visible, the overload relay is not tripped. If the red indicator is visible,

the overload relay is tripped.

Accessory Modules Universal Protection Module and Remote Reset Module

The Universal Protection Module and the Remote Reset Module both include an LED status

indicator that shows the state of the E100 relay. The modules are supplied with external power,

so in the event of a fault event, the status LEDs still operate.

ATTENTION: Servicing energized industrial control equipment can be

hazardous. Electrical shock, burns, or unintentional actuation of controlled

industrial equipment may cause death or serious injury. For safety of

maintenance personnel and others who may be exposed to electrical hazards

associated with the maintenance activities, follow the local safety-related

work practices (for example, the NFPA 70E, Part II, Electrical Safety for

Employee Workplaces, in the United States) when working on or near

energized equipment. Maintenance personnel must be trained in the safety

practices, procedures, and requirements that pertain to their respective job

assignments. Do not work alone on energized equipment.

ATTENTION: Do not attempt to defeat or override fault circuits. The cause of

a fault indication must be determined and corrected before attempting

operation. Failure to correct a control system or mechanical malfunction may

result in personal injury and/or equipment damage due to uncontrolled

machine system operation.

16 Rockwell Automation Publication 193-UM013C-EN-P - November 2022

Chapter 3 Troubleshooting

The status LED indicates the cause of a trip by flashing a red trip code. The number of flashes

followed by a pause identifies the specific trip code as shown in Table 4.

Remote Indication Display

There are four LED status indicators on the front of the Cat. No. 193-ERID and 193-1ERIDN

modules. These status indicators show Module Power/Status, Overload, Phase Loss, and Fault

Status. See Figure 7

Figure 7 - Cat. No. 193-ERID and 193-E1ERIDN Remote Indication and Display Module Features

Table 5 lists the status, warning, and fault codes for the remote indication and display

modules.

Table 3 - 193-1EGJ and 193-1ERR Remote Indication and Display Module Fault/Status Codes

Status

Indicator Color

Solid/Flashing Description Solution

Green

Flashing Module powered —

Solid

Module powered and motor

current present

—

Amber Flashing Warning

Red

Flashing

Fault detected and overload

relay tripped

Use Table 4

to identify the specific trip code

Solid

Hardware fault; internal

hardware fault detected and

overload relay trip attempted

• Recover fault by cycling overload relay

accessory supply voltage

• Verify that the supply voltage is within limits

• Verify the wiring to the terminals is correct

• Verify that the pins that connected the

accessory to the overload relay are not

damaged or misaligned

• Verify the operating temperature of the

devices is within specification limits

Table 4 - Trip Code Identification

No. of Flashes Trip Type

1Overload Trip

2Phase Loss

3Ground Fault

5Jam

8 Short Circuit

10

COM Loss

(1)

(1) If you experience repeated COM Loss trips, this may be due to a damaged

communication interface cable. To test whether this is the case, unplug the

communication interface cable from the communication port and wait at least 3

seconds before re-connecting. If the issue persists, consider replacing the

communication interface cable.

11 Test Trip

Reset (193-ERID only)

Module Power/Status

Fault Status

Phase Loss

Overload

Rockwell Automation Publication 193-UM013C-EN-P - November 2022 17

Chapter 3 Troubleshooting

Table 5 - 193-ERID and 193-E1ERIDN Remote Indication and Display Module Fault/Status Codes

Status Indicator Symbol Status Indicator Color

Solid/

Flashing

Description

Module Power/

Status

Green

Flashing Module powered

Solid

Module powered and motor current

present

Red Solid Hardware fault

Overload

Red Solid Overload trip

Amber Flashing

Overload warning

(1)

(1) An Overload warning occurs when the E100 overload reaches 90% thermal capacity utilization (TCU ). The overload trips at

100% TCU.

Phase Loss

Red

Solid Short Circuit Trip

Flashing Phase Loss Trip

Amber Flashing

Phase Loss Warning

(2)

(2) Phase Loss warning is active if the overload detects a Phase Loss condition. The warning is maintained for 3 seconds before

a Phase Loss Trip occurs.

Fault Status

Red 3 Flashing

Ground Fault Trip

(3)

(3) A Ground Fault trip occurs if the configured Ground Fault Level is reached for 100 ms.

Amber 3 Flashing Ground Fault Warning

Red 5 Flashing Jam Trip

Amber 5 Flashing

Jam Warning

(4)

(4) A Jam warning is active if the measured FLA is greater than the set Jam Level. The warning is active until the Jam Delay time

is reached and the overload relay trips.

Red 9 Flashing

Welded Contact

(5)

(5) Does not apply to the E100 relay.

Red 10 Flashing Comm Loss

Amber 10 Flashing Comm Warning

Red 11 Flashing Test Trip

18 Rockwell Automation Publication 193-UM013C-EN-P - November 2022

Chapter 3 Troubleshooting

Notes:

Rockwell Automation Publication 193-UM013C-EN-P - November 2022 19

Appendix A

Wiring Diagrams

E100 Wiring Configurations The following pages illustrate various wiring configurations for the E100™ Electronic Overload

Relay.

Figure 8 - 3-Phase, Full-voltage Direct-on-line Starter, NEMA Symbology

Figure 9 - 3-Phase, Full-voltage Direct-on-line Starter, IEC Symbology

95

L2 L3 13L1

14

A1

A2

T2 T3T1

96 97 98

T1 T3

T2

Connection must be

fitted by the user

Short-circuit

Protection Device

95

3

13

1

14

A1

A2

462

96

U

V

5

97 98

W

Connection must be

fitted by the user

Short-circuit

Protection Device

20 Rockwell Automation Publication 193-UM013C-EN-P - November 2022

Appendix A Wiring Diagrams

Figure 10 - 1-Phase, Full-voltage Direct-on-line Starter, NEMA Symbology

Figure 11 - 1-Phase, Full-voltage Direct-on-line Starter, IEC Symbology

Figure 12 - E100 Overload Relay with External Current Transformer

For more information about how to install an external Current Transformer, see

Bulletin 193 Core Balanced Ground Fault Sensor Application and Installation

Instructions, publication 193-IN047

.

95

L2 L3 13L1

14

A1

A2

T2 T3T1

96 97 98

T1 T2

Connection must be

fitted by the user

Short-circuit

Protection Device

Connection must be

fitted by the user

95

35

13

1

14

A1

A2

462

96 97 98

U1 U2

Connection must be

fitted by the user

Short-circuit

Protection Device

Connection must be

fitted by the user

M

L1/1

L1/1

T1/2

T2/4 T3/6

L2/3

L3/5

L2/3 L3/5

H1(Dot) H1(Dot) H1(Dot)

H2 H2 H2

X1

X1 X1

X2X2X2

CT1

T1/2

T2/4

T3/6

CT2 CT3

Overload Relay

Rockwell Automation Publication 193-UM013C-EN-P - November 2022 21

E100 Electronic Overload Relay User Manual

Notes:

Publication 193-UM013C-EN-P - November 2022

Supersedes Publication 193-UM013B-EN-P - December 2019 Copyright © 2022 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Rockwell Automation Support

Use these resources to access support information.

Documentation Feedback

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the

form at rok.auto/docfeedback.

Waste Electrical and Electronic Equipment (WEEE)

Rockwell Automation maintains current product environmental compliance information on its website at rok.auto/pec.

Technical Support Center

Find help with how-to videos, FAQs, chat, user forums, Knowledgebase, and product

notification updates.

rok.auto/support

Local Technical Support Phone Numbers Locate the telephone number for your country. rok.auto/phonesupport

Technical Documentation Center

Quickly access and download technical specifications, installation instructions, and user

manuals.

rok.auto/techdocs

Literature Library Find installation instructions, manuals, brochures, and technical data publications. rok.auto/literature

Product Compatibility and Download Center

(PCDC)

Download firmware, associated files (such as AOP, EDS, and DTM), and access product

release notes.

rok.auto/pcdc

At the end of life, this equipment should be collected separately from any unsorted municipal waste.

Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752, İçerenköy, İstanbul, Tel: +90 (216) 5698400 EEE Yönetmeliğine Uygundur

Allen-Bradley, E100, expanding human possibility, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

EtherNet/IP is a trademark of ODVA, Inc.<<<Third-party trademarks from Brand Identity list.

Trademarks not belonging to Rockwell Automation are property of their respective companies.