Vacuum Chamber Packaging Machine

Owner’s Manual

21

00

Effective Serial 5512+

860804• Revision AE • 02/19

THE NEW STANDARD FOR INNOVATION

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

I

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

INTRODUCTION

TABLE OF CONTENTS

General ...............................................III

Specifications ....................................... IV

SAFETY

Personal Safety ....................................1.1

Food Safety ........................................1.2

General Safety Guidelines ....................1.2

Safety Decal Locations ........................ 1.3

Machine Conformity ............................1.4

STARTUP

Unpacking ..........................................2.1

Power Requirements ............................. 2.1

Grounding Instructions ........................ 2.2

Vacuum Pump .................................... 2.3

Checking Vacuum Pump Rotation ........ 2.3

Gas Flush Connection ........................ 2.3

Air-Assist Connection .......................... 2.3

Installation of Perforating Knives .......... 2.4

Installation of Precut Knives ................. 2.4

OPERATION

Placement of Product ...........................3.1

Operation with Digital Control Panel .... 3.2

Operator Menu on Digital Panel .......... 3.3

Selecting a New Program .................... 3.5

Operation with Touchscreen ................ 3.6

Sealing with Air-Assist ........................ 3 .11

Gas Flush Option .............................. 3.11

Double Seam Seal Option ................. 3.11

10mm Wide Seam Seal Option .......... 3 .11

Perforating Knife Option ....................3.12

Precut Option ...................................3.12

MAINTENANCE

Prior to Cleaning .................................4.1

Cleaning Recommendations .................4.1

Vacuum Pump Maintenance ................ 4.2

Seal Bar Maintenance ......................... 4.2

Reading the Indicators ........................ 4.4

Troubleshooting ................................. 4.5

Supervisor Menu on Digital Panel ........ 4.7

Supervisor Menu on Touchscreen ........ 4.12

Changing Vacuum Pump Oil and Filter 4.18

Maintenance Log ............................. 4.20

Service Log .......................................4.21

SCHEMATICS

Designation and Function of Controls .... 5.1

230 Volt, Single Phase, Digital Panel .... 5.2

230 Volt, 3 Phase, Digital Panel ........... 5.3

380 Volt, 50 Hz, Digital Panel ............. 5.4

380 Volt, 50 Hz, Digital Panel w/o N ... 5.5

460 Volt, 3 Phase, Digital Panel ........... 5.6

575 Volt, 3 Phase, Digital Panel ........... 5.7

Pneumatic Diagram ............................ 5.8

PARTS

Recommended Spare Parts ...................6.1

Miscellaneous Machine Parts ............... 6.2

Lid, External ....................................... 6.3

Lid, Internal ........................................ 6.4

Legs and Pump .................................. 6.6

Double Seam Seal Bar ........................ 6.8

10mm Wide Seal Bar.......................... 6.9

Single Seam Seal Bar .........................6.10

Vacuum Manifold .............................. 6 .11

Main Electrical Components ...............6.12

Base ................................................6.14

Gas Flush .........................................6.16

Swing Arm Assembly ..........................6.18

Digital Control Panel ........................ 6.20

Touchscreen Control Panel .................6.21

Inline Filter ....................................... 6.22

REFERENCE MANUALS

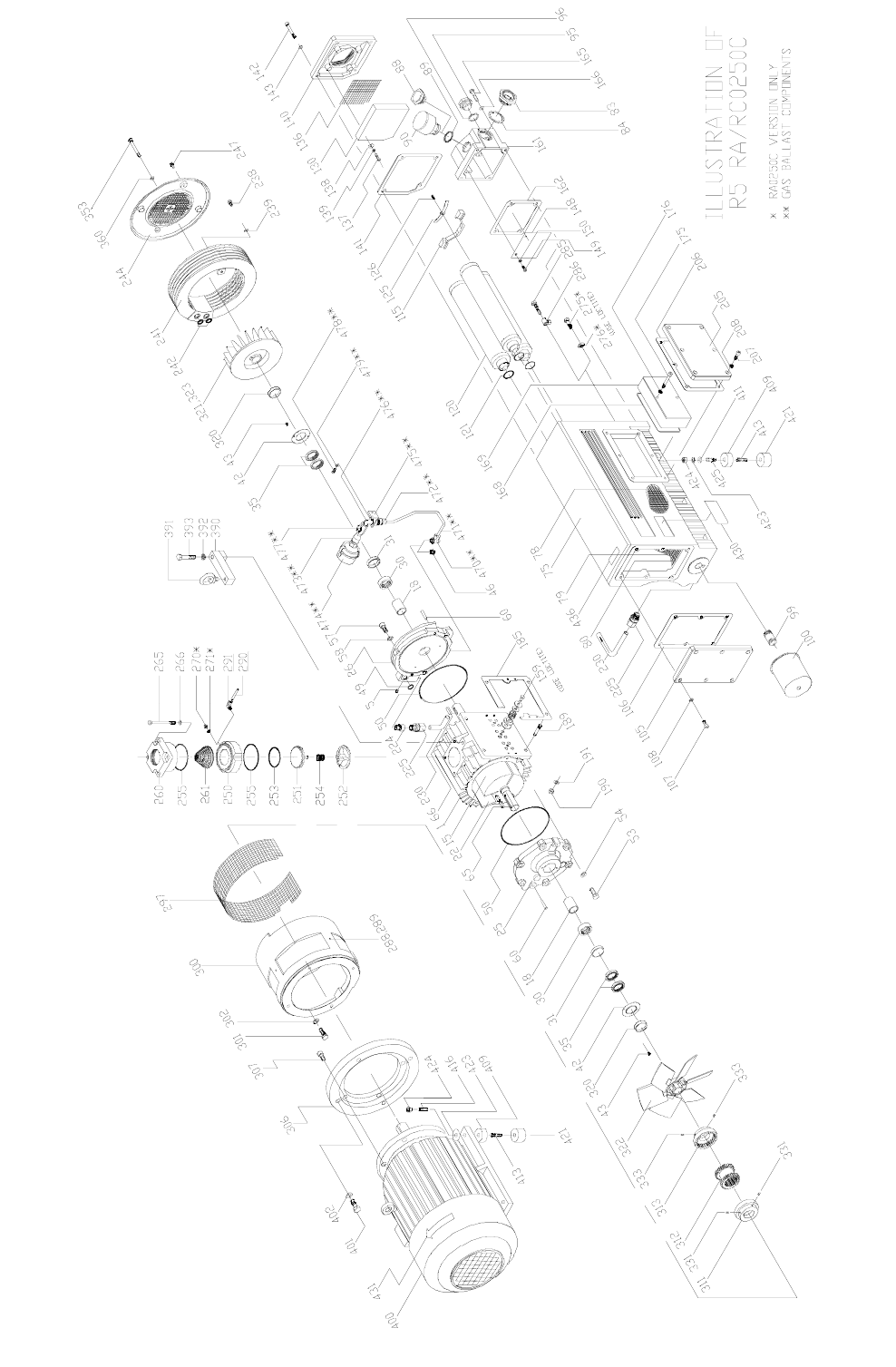

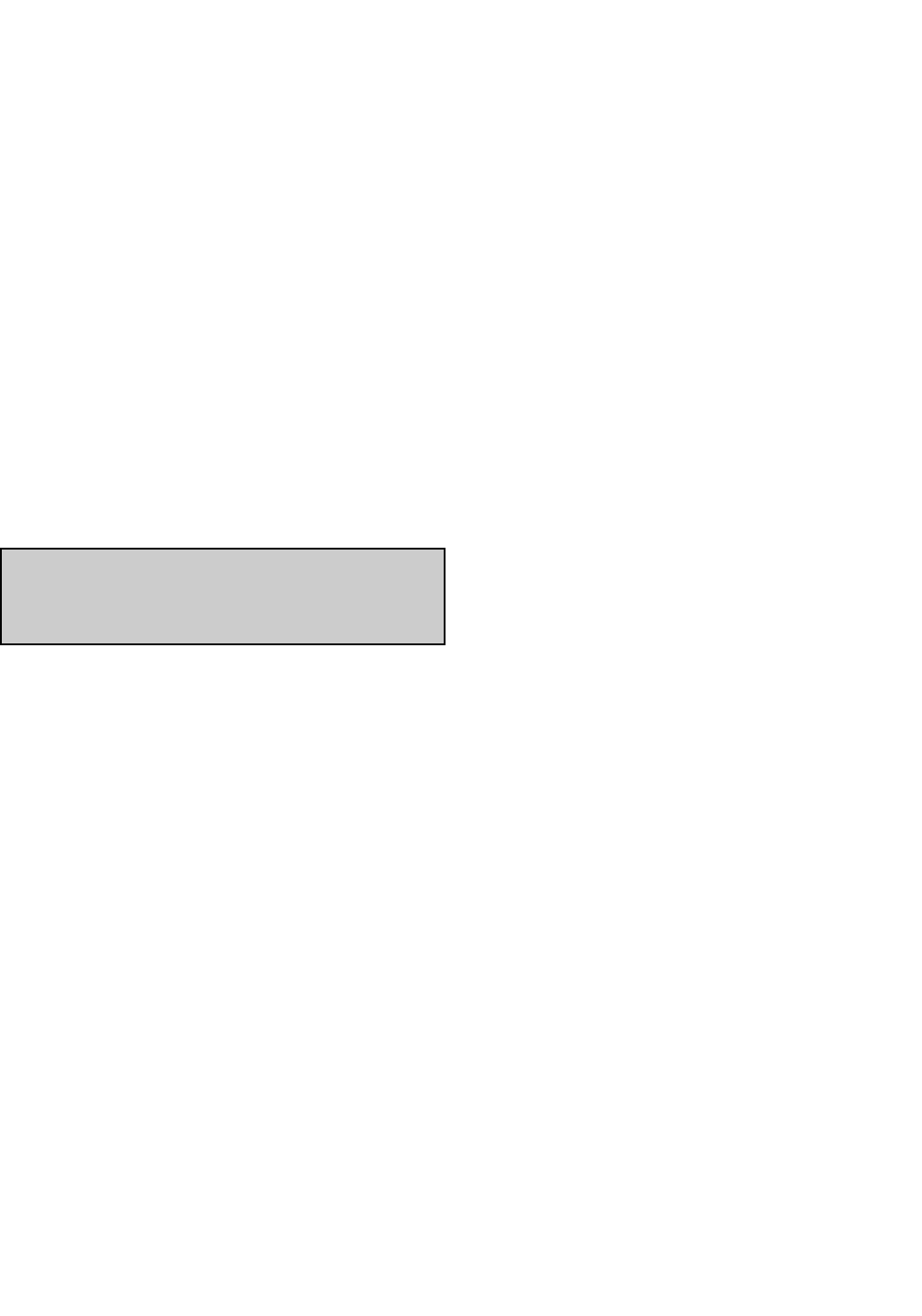

R5 Series Vacuum Pumps ..................... 7.1

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

II

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

II

INTRODUCTION

II

ULTRASOURCE LLC

Ultravac

®

2100

Vacuum Chamber Packaging Machine

Owner’s Manual

Congratulations on your Ultravac

®

2100 vacuum packaging machine purchase. This

machine was designed to provide years of trouble-free operation and to help in the

packaging of your quality food products.

Please read this owner’s manual to gain the maximum benefits of your vacuum packaging

machine and its different components.

A note about cleaning: Given all the various ways equipment is used in different

environments, we recommend the owner consult sanitation experts on how to properly

clean each piece of machinery in their plant and to do bacterial testing to insure that the

equipment is cleaned properly.

For Sales, Call:

Phone (816) 753-2150 • Fax (816) 753-4976

Toll-Free (800) 777-5624

For Replacement Parts, Call:

Phone (816) 753-2150 • Fax (816) 561-2854

Toll-Free (800) 777-5624

For Technical Support, Call:

Phone (816) 753-2150 • Fax (816) 753-4976

Toll-Free (800) 777-5624

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

INTRODUCTION

III

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

General

This owner’s manual contains information pertinent to your Ultravac

®

2100. Basic

instructions and maintenance information is provided. Please read carefully. Failure to do so

could result in bodily injury and/or damage to the equipment.

Receiving Problems: As in all cases, before signing the bill of lading, be sure all items

have been received as listed and there is no damage in shipment. If needed, a claim must

be made immediately to the local truck line office and noted on the bill of lading.

Please fill in the information from the bill of lading and the product identification tag.

Model No.

Serial No.

Ship Date:

Owner:

Location:

Electrical service size for your Ultravac

®

2100 (check one):

208 Volt, 3 phase, 60 Hz

230 Volt, 3 phase, 60 Hz

230 Volt, Single phase, 60 Hz

380 Volt, 3 phase, 50 Hz

460 Volt, 3 phase, 60 Hz

575 Volt, 3 phase, 60 Hz

Pump horsepower size for your Ultravac

®

2100 (check one):

5-horsepower

7.5-horsepower

10-horsepower

12-horsepower

Please fill in the serial numbers from the pump identification tags:

Serial No.

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

IV

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

IV

INTRODUCTION

IV

Specifications

A

F

G

D

E

H

B

C

Figure 0.1

8-in. Model 12-in. Model

Length (A): 1638mm (64.5-in.) 64.5-in. (1638.3mm)

Width (B): 1067mm (42-in.) 1067mm (42-in.)

Maximum Height (C): 1194 m m (47-in .) 1295mm (51-in.)

Working Height (D): 874mm (34.4-in.) 874mm (34.4-in.)

Chamber Width (E): 785mm (30.9-in.) 785mm (30.9-in.)

Chamber Length (F): 676mm (26.6-in.) 676mm (26.6-in.)

Chamber Depth (G): 203mm (8-in.) 305mm (12-in.)

Between Seal Bars (H): 813mm (32-in.) 813mm (32-in.)

Seal Bar Length: 673mm (26.5-in.) 673mm (26.5-in.)

Vacuum Pump:

200 m

3

/h, (117 cfm) 5.6 kW (7½ hp) [8-in. Model Only]

306 m

3

/h, (180 cfm) 7.5 kW (10 hp)

360 m

3

/h, (212 cfm) 8.9 kW (12 hp)

Cycle Time: 15-25 seconds 15-25 seconds

Net Weight: 5 0 0kg (110 4 -l b s .) 559kg (1232-lbs.)

Construction:

USDA Acceptable for use in

federally-inspected meat/poultry plants

ETL-approved

Cast Aluminum

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

1.1

SAFETY

SAFETY

Personal Safety

The procedures and guidelines herein must be followed precisely to avoid problems that can

result in property damage, personal injury, or death. If you have any questions related to

this information, please contact Ultravac Services Inc. at (800) 777-5624.

DANGER

Hazardous voltage.

Disconnect and lockout power before servicing machine or cleaning. Do not remove panels

unless power has been disconnected and locked out at risk of electric shock hazard.

DANGER

Hot oil.

Hot oil poses scalding risk. Take necessary precautions while draining warm oil.

WARNINGWARNING

Read and understand owner’s manual before using this machine. Failure to follow operating

instructions could result in personal injury or damage to equipment.

WARNINGWARNING

Explosion hazard.

Do not use a gas with an oxygen content greater than 22% with gas flush option.

CAUTIONCAUTION

Blade hazard.

Do not remove, install, or replace blades without protective gloves. Perforating knife blade

is sharp. Use care when handling.

CAUTIONCAUTION

Blade hazard.

Do not remove, install, or replace blades without protective gloves. Precut knife blade is

sharp. Use care when handling.

CAUTIONCAUTION

Cleaning agents.

Do not get the cleaning agents in eyes, on skin, or on clothing. Always wear rubber gloves,

goggles, and protective clothing when contact is likely. Consult product manufacturer for

specific details.

Signal words used in classification of potential hazards are defined as follows:

DANGER: Indicates an imminently hazardous situation, which, if not avoided, may result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation, which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation, which, if not avoided, may result in minor or

moderate injury. Caution also indicates actions that may cause property damage.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

1.2

1.2

SAFETY

Food Safety

Food Packaging

While this machine is often used for food packaging and vacuum cooking, there are

inherent risks associated with this packaging technique that could cause serious illness

or death to the consumer of the food product. If you are using this machine for a food

application, you must consult with a reputable food technologist or specialist in vacuum/

modified atmosphere packaging (M.A.P.) to review the safety of your application.

Gas Flush

In order to ensure proper shelf life of the food product packaged in this machine, you

must contact a reputable food technologist or specialist in vacuum/modified atmosphere

packaging (M.A.P.) to review and develop the appropriate gas mixture for your package,

and you must perform quality control and gas analysis on your finished M.A.P. packages.

General Safety Guidelines

Obvious safety guidelines should be observed.

Use a certified electrician to install permanent electrical connection for your packaging

machine. Failure to do so may result in death or serious injury and/or permanent

damage to the machine.

Be sure to turn off power to your packaging machine before any maintenance work is

performed.

Disconnect and lockout power to your packaging machine before any maintenance work

is performed.

Place machine on a flat, stable surface.

Do not place tools, parts, or other objects on or inside machine while operating.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

1.3

SAFETY

Safety Decal Locations

Part # 860988 (Qty. 1)

Part # 889599 (Qty. 1)

Part # 861196 Qty. 1

(attached to power cord)

Part # 860360 Qty. 1

(attached to power cord)

Factory Tested / Oil Filled

(Hanging Tag)

Part # 835440 (Qty. 2)

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

1.4

1.4

SAFETY

Machine Conformity

This machine has been manufactured to conform to the following safety standards:

UL 73, Motor Operated Appliances, USA

The Ultravac 2100 is manufactured to conform to the relevant provisions of ANSI/UL-73,

Tenth Edition dated 03/2011, Revised 01/2012.

CSA 22.2, No. 68, Motor Operated Appliances, Canada

The Ultravac 2100 is manufactured to conform to the relevant provisions of CSA C22.2 No.

68-09, Seventh Edition, Update #2 dated 09/2010.

CE Low Voltage Directive (LVD) 2006/95/EC

The Ultravac 2100 is manufactured to conform to the relevant provisions of

• EN 60335-1-2012 relating to “Safety of household and similar electrical appliances,”

• EN 60335-2-64:2000 relating to “Particular requirements for commercial electric kitchen

machines.”

and overall the provisions of Low Voltage Directive (LVD) 2006/95/EC relating to

“Equipment designed for use within certain voltage limits of 12 December 2006.”

CE Electromagnetic Compatibility (EMC) Directive 89/336/EEC

The Ultravac 2100 is manufactured to conform to the relevant provisions of

• EN 61000-6-4 relating to “Emissions, Radiated, 30Mhz - 1Ghz”

• EN 61000-6-2 relating to “Emissions, Conducted, 150kHz - 30Mhz”

• EN 61000-4-2 relating to “Immunity ESD ± 4kV Contact/ ±8kV air discharge “

• EN 61000-4-3 relating to “Immunity Radiated RF, 10V/m, 80Mhz - 2.7Ghz”

• EN 61000-4-4 relating to “Immunity EFT (Mains) ±1kV”

• EN 61000-4-5 relating to “Immunity Surge AC, ±2kV”

• EN 61000-4-6 relating to “Immunity Conducted RF (Mains), 10Vrms.”

and overall the provisions of “Electromagnetic Compatibility (EMC) Directive 89/336/EEC of

15 December 2004.”

USDA / AMI Sanitary Design Standards

The Ultravac 2100 is designed for sanitary conditions in USDA inspected facilities. All

UltraSource equipment is manufactured with respect to AMI Sanitary Design Standards. All

materials that are in food contact areas meet relevant USDA standards.

The Design and Technical Construction files for this machine are maintained at:

UltraSource LLC

1414 West 29th Street

Kansas City, MO 64108-3604 USA

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

STARTUP

2.1

STARTUP

Unpacking

1. Carefully remove crate from the skid.

2. Remove machine from skid.

3. Wipe down outside of the machine.

Power Requirements

The machine is available with a 7½ horsepower vacuum pump for the 200mm (8-in.) model

and a 10 horsepower vacuum pump for the 300mm (12-in.) model. The standard machine

is rated 220 volt, 60 Hertz, 3 phase and is supplied with a 30 amp, 250 volt, 3 phase plug.

The owner must supply the correct 3 phase or single phase power source in accordance

with the National Electric Code. The table below is based on the National Electric Code and

is to be used as a guide in wire size selection and short circuit protection. The requirements

noted in the table may change. Please consult an electrician prior to installation.

UV2100 POWER CABLE SIZING CHART

208/230v (5&7.5hp Pumps) 10 gauge/ 4 conductor

380v 12 gauge/ 5 conductor

460v 10 gauge/ 4 conductor

208/230v (10&12hp Pumps) 8 gauge/ 4 conductor

380v w/o neutral 12 gauge/ 4 conductor

Customer Voltage

Pump Motor Full Load Amps

Supply conductor shall Supply conductor shall

have an ampacity not have an ampacity not

less than 125% of the less than 125% of the

Pump Motor Full Load Pump Motor Full Load

AmpsAmps

5 HP 7.5 HP 10 HP 12 HP

208, 60 Hz 3 Phase 21 26.5 32

230, 60 Hz 3 Phase 20.5 26 30

380, 50 Hz 3 Phase 12 14 15

460, 60 Hz 3 Phase 10.5 13 15

575, 60 Hz 3 Phase 9 10.5 12.5

230, 60 Hz Single Phase 22.5 - - -

Customer Voltage

Inverse Time Circuit

Breaker

Fused Disconnect Dual

Element (Time Delay)

5 HP 7.5 HP 10 HP 12 HP 5 HP 7.5 HP 10 HP 12 HP

208, 60 Hz 3 Phase 50 60 70 35 45 50

230, 60 Hz 3 Phase 50 60 60 35 45 50

380, 50 Hz 3 Phase 25 30 35 20 20 25

460, 60 Hz 3 Phase 25 30 35 15 20 25

575, 60 Hz 3 Phase 20 25 30 15 15 20

230, 60 Hz Single Phase 60 - - - 45 - - -

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

2.2

STARTUP

Grounding Instructions

The Ultravac

®

2100 must be grounded. In the event of malfunction or breakdown,

grounding provides a path of least resistance for electric current to reduce the risk of electric

shock. The unit is equipped with an equipment-grounding conductor cord and a grounding

plug. The plug must be plugged into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

DANGER

Hazardous voltage.

Improper connection of the equipment-grounding conductor can result in a risk of electric

shock.

The equipment-grounding conductor outer surface is green with or without yellow

stripes. If repair or replacement of the cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal. Check with a qualified electrician

or Ultravac Services Inc. technician if the grounding instructions are not completely

understood, or if there is doubt as to whether the unit is properly grounded. Do not modify

the plug provided with the unit – if it will not fit the outlet; have a proper outlet installed by

a qualified electrician.

DANGER

OXYGEN ENRICHED USE

ULTRASOURCE TRAY SEALING AND VACUUM CHAMBER MACHINES ARE NOT DESIGNED

FOR USE WITH OXYGEN ENRICHED PROCESS GASES. ANY APPLICATION THAT REQUIRES

A PROCESS GAS CONTAINING 25% OR MORE OXYGEN SHOULD CONTACT ULTRAVAC

SERVICES AT (800) 777-5624 AS RETROFIT OPTIONS ARE REQUIRED.

RUNNING THIS MACHINE WITH AN OXYGEN ENRICHED PROCESS GAS, WITHOUT THE

NECESSARY RETROFIT KIT COULD CAUSE SEVERE INJURY, DAMAGE OR DEATH.

ULTRASOURCE TRAY SEALING AND VACUUM CHAMBER THAT ARE RETROFITTED

WITH THE NECESSARY KIT WILL HAVE A DECAL ABOVE OR BESIDE THE GAS SUPPLY

CONNECTION INDICATING THE MACHINE’S READINESS TO RUN OXYGEN ENRICHED

PROCESS GASES.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

STARTUP

2.3

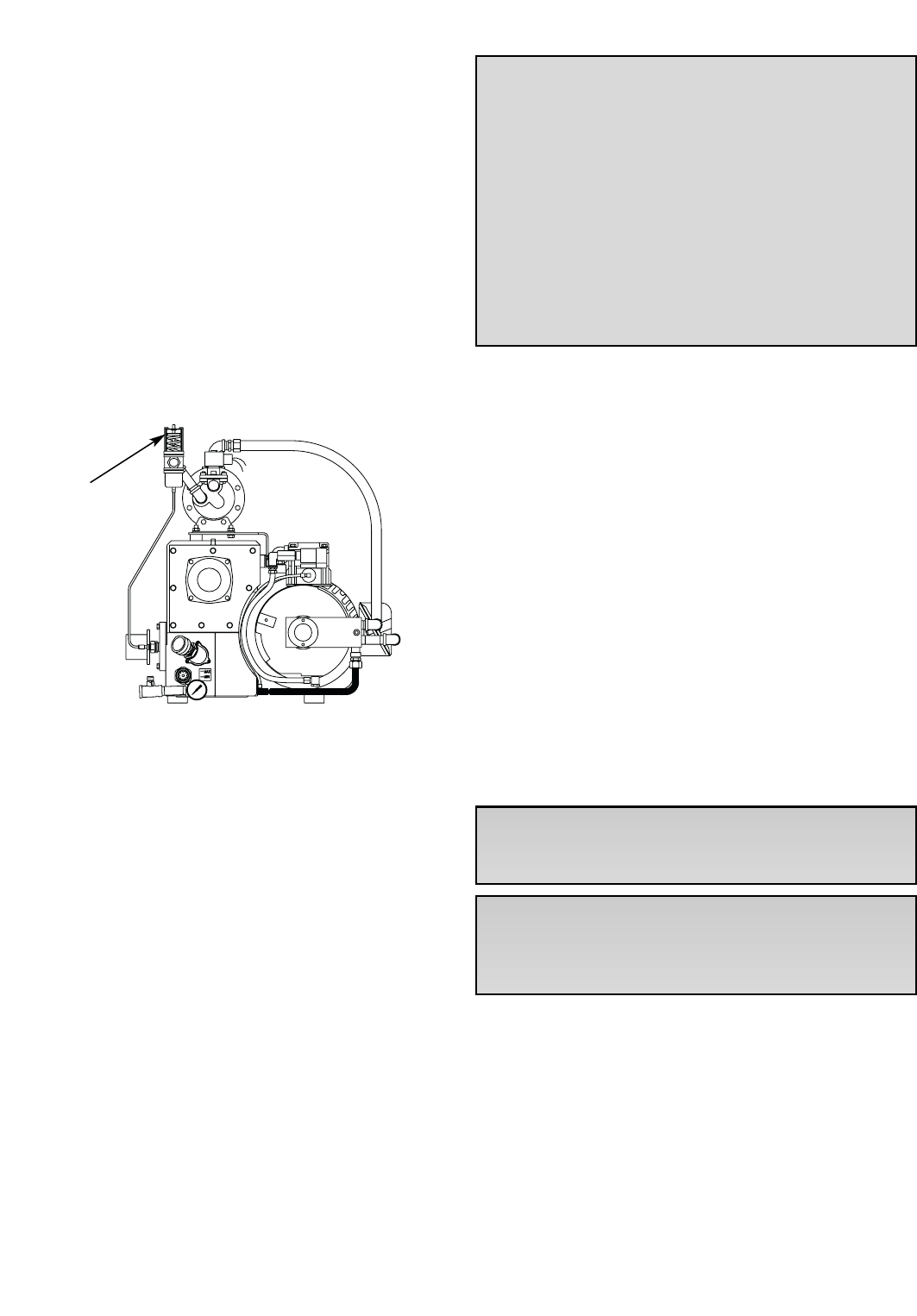

Vacuum Pump

It is essential to check the oil level daily and to change the oil after every 500 hours of

operation. Read the oil level with the machine turned off. Oil may be added until the level

reaches the MAX level shown below. Refer to page 4.18 for details on changing the oil.

NOTE: ALL ULTRAVAC 2100 CHAMBER MACHINES ARE SHIPPED WITH OIL IN THE PUMP.

ALTHOUGH THE FACTORY RECOMMENDS CHECKING THE OIL LEVEL PRIOR TO FIRST

USE!

Checking Vacuum Pump Rotation

Caution: Check oil level of pump before starting pump (please refer to pump manual).

To check the direction of the pump rotation, briefly engage the “POWER ON” switch and

observe the motor fan at the end of the pump. The fan should rotate as indicated by the

arrow on the fan cover. To correct the rotation, switch any two phases in the plug.

Gas Flush Connection

The owner must supply a suitable regulator with a range of 0 to 60 p.s.i. We recommend

using food-grade flexible hose with a 1/4-in. I.D. and a maximum length of 15-ft. Maximum

regulator pressure is 55 p.s.i.

Air-Assist Connection

The machine is equipped with a regulator for air-assisted sealing. The hose barb will

accept 1/4-in. I.D. hose. The recommended air supply is 75 p.s.i. at 6 c.f.m. The maximum

regulator setting is 40 p.s.i.

Figure 2.1

MAX

MIN

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

2.4

STARTUP

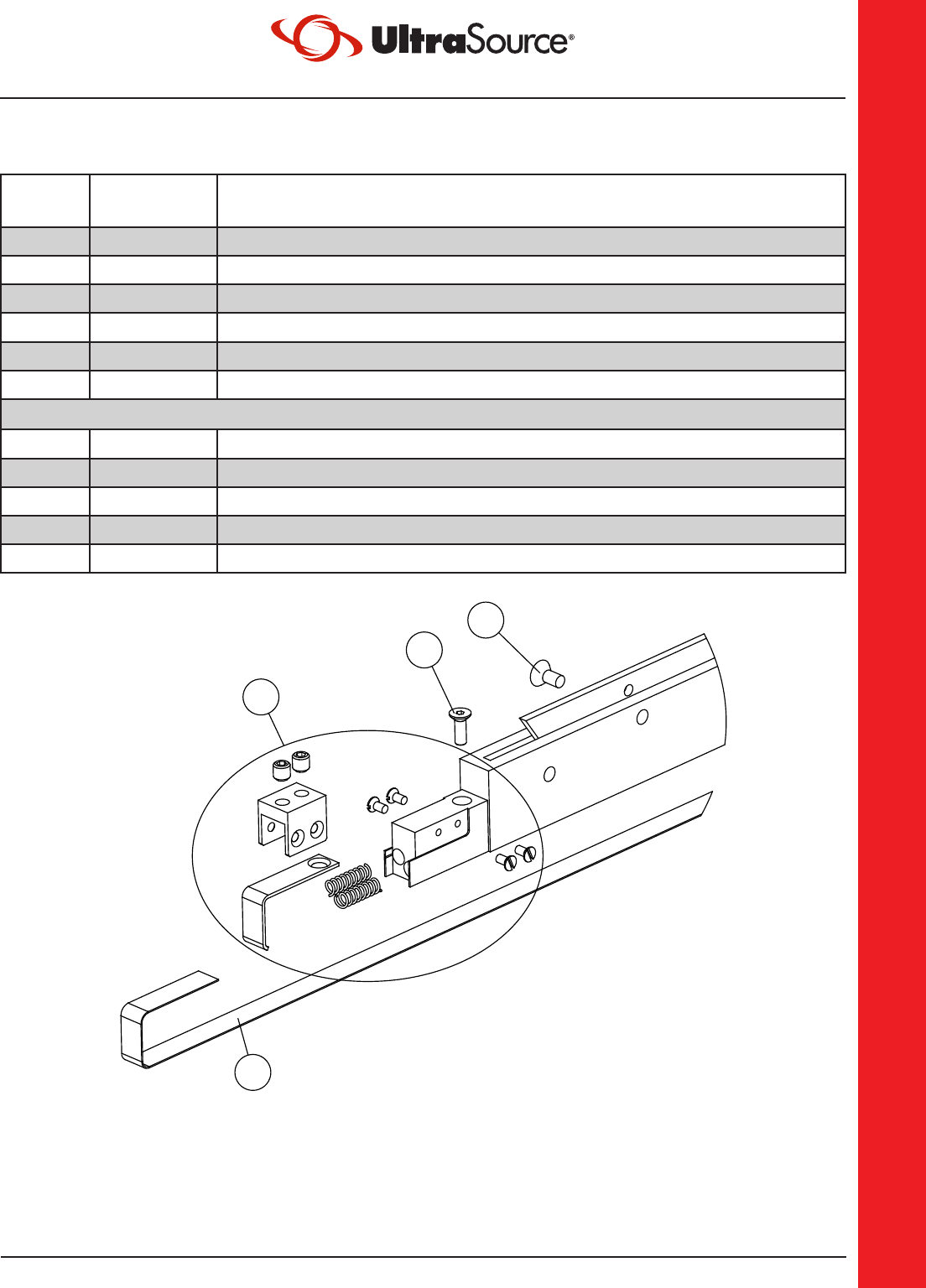

Installation of Perforating Knives

CAUTIONCAUTION

Blade hazard.

Do not remove, install, or replace blades without protective gloves. Perforating knife blade is

sharp. Use care when handling.

Remove standard seal bars. Install perforating bars with the cutting blade facing toward

the outside of the lid. The use of air-assist is required for proper operation. The air-assist

regulator should be set at 20 to 30 p.s.i., not to exceed 40 p.s.i.

As the backup strip wears, it can be removed and changed end for end for a better surface.

The strip may also be turned upside down when one side is worn.

Installation of Precut Knives

CAUTIONCAUTION

Blade hazard.

Do not remove, install, or replace blades without protective gloves. Precut knife blade is sharp.

Use care when handling

Remove standard seal bars. Install precut seal bars with the blade facing toward the outside

of the lid. The use of air-assist is required for proper operation. The air-assist regulator

should be set at 20 to 30 p.s.i., not to exceed 40 p.s.i.

As the backup strip wears, it can be removed and changed end for end for a better surface.

The strip may also be turned upside down when one side is worn.

Figure 2.2

Precut Knife

this side

Excess Pouch

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.1

OPERATION

OPERATION

Placement of Product

For best sealing results, it is important to:

• Check the pump oil level daily.

• Select a pouch that fits the product.

• Carefully load the product into the pouch.

• Keep the product and the product residue away from the seal area of the pouch.

• Place the product as far into the pouch as possible.

• Maintain an equal amount of the product above and below the seal bar (see figure

below on use of filler plates).

• Lay the pouch flat on the seal area, keeping the pouch free of wrinkles.

• Place the pouch so that the open end is inside the chamber when the lid is closed.

Figure 3.1

Products containing liquid or loose particles can be packaged by slightly loosening the nuts

on each end of the machine and tilting the machine to the desired angle. Retighten the nuts

to secure the machine.

Figure 3.2

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.2

OPERATION

Operation with Digital Control Panel

The digital control panel allows the user more options than the standard control panel. The

embedded microprocessor controls each sequence of the packaging operation. Settings for

the vacuum, gas, and sealing are entered as parameters through the keypad. This allows

the user to custom program every step of the packaging process. The precise vacuum

and gas pressures are controlled by a pressure based sensor. The vacuum pressure, gas

pressure, and seal time are displayed on a large 16-character LCD backlit readout, which

is easily readable in all lighting conditions. As each sequence is performed, the real-time

pressure level or cycle time is displayed.

The digital front panel can save up to ten pre-programmed routines, which can be retrieved

at any time for specific packaging applications. With the supervisor security feature turned

on, these programs cannot be inadvertently changed.

The Vacplus option allows the operator to run the pump from 0 to 20 seconds after the set

vacuum level is achieved.

The Gas Flush option allows the operator to introduce an inert gas into the chamber after

the vacuum stage. This option can be used as a filler to prevent crushing of the product

after sealing, as a means to prolong shelf life, or as a means to maintain desirable product

appearance.

The digital front panel has an auto stop, which will automatically seal if the preset vacuum is

not reached. This feature decreases the cycle time and optimizes the vacuum level of each

product.

The digital front panel, which includes the keypad, illuminated display, and microprocessor,

use sealed components and is conformal coated in a moisture-proof coating. The digital

front panel meets or exceeds the requirements of NEMA 4. The front of the digital display is

sealed and flush for easy cleaning.

The digital control has both pulsed vacuum and pulsed venting options for fragile product.

The digital control has a maintenance screen for testing valves and a special loop option for

multiple vacuum/gas cycles before sealing.

Figure 3.4

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.3

OPERATION

Operator Menu on Digital Panel

NOTE: if the supervisor has set security on, these settings cannot be changed.

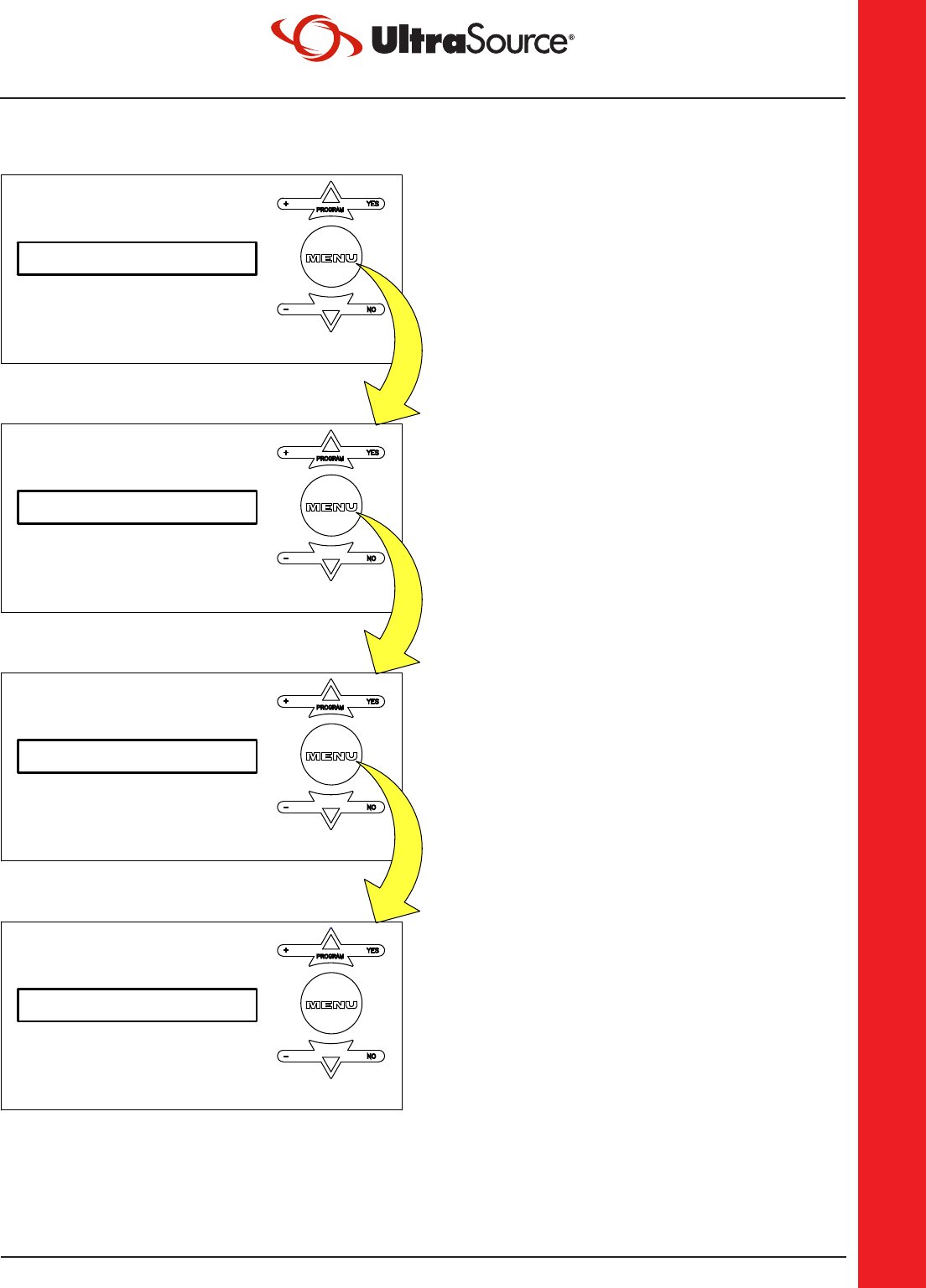

Figure 3.5

VACPLUS: 4.0

SEAL: 1.2

VACUUM: 98

RUNNING PROG: 1

NO

-

+

PROGRAM

YES

-

NO

YES

PROGRAM

+

NO

-

YES

+

PROGRAM

YES

PROGRAM

+

-

NO

This is the Main Menu screen. When

the machine starts up, the last program

that was run will be the current program

shown in the window. To set the operating

parameters for the program shown press

the MENU Key.

VACUUM is set to % vacuum using the UP

and DOWN arrow keys. The range is 30%

to 99%.

Press the MENU Key.

VACPLUS may be set greater than zero

to allow the pump to continue evacuating

the chamber (for the specified number

of seconds) after the pressure in the

chamber has reached the % vacuum set

in the vacuum menu. The range is 0 to 20

seconds.

Press the MENU Key.

The SEAL setting is in seconds.

Use the UP and DOWN arrow keys to

change the seal time. The range is 0 to 2

seconds.

Press the MENU Key.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.4

OPERATION

Operator Menu on Digital Panel (continued)

WARNINGWARNING

Explosion hazard.

Do not use a gas with an oxygen content greater than 22% with gas flush option.

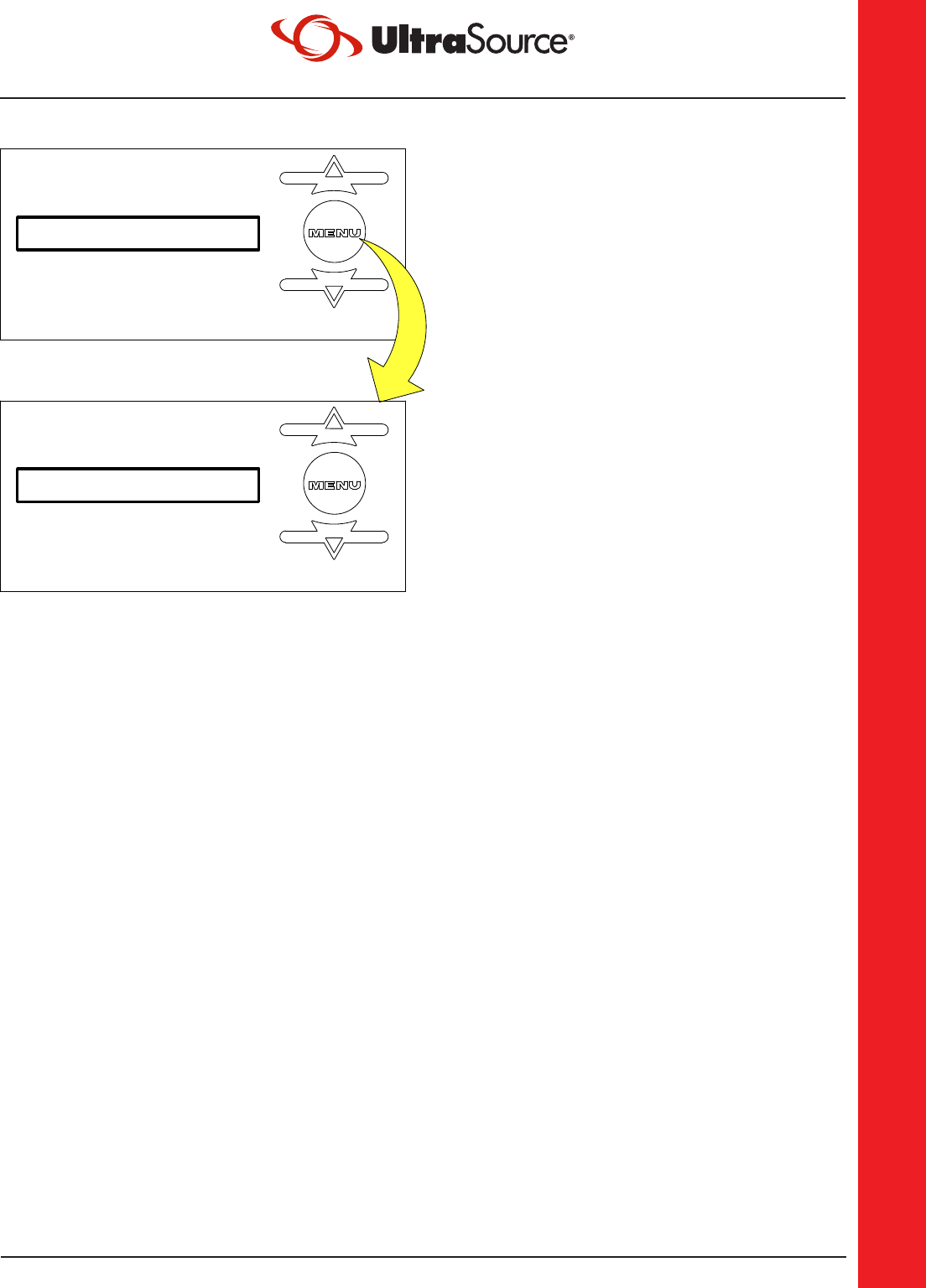

Figure 3.5

PRECUT: YES

GAS: 65

GAS: YES

NO

-

YES

+

PROGRAM

NO

-

YES

+

PROGRAM

NO

-

YES

+

PROGRAM

If the machine is equipped with the gas

option, it can be turned ON or OFF by

pressing the UP or DOWN arrow keys.

Press the MENU Key.

GAS is set to % gas using the UP and

DOWN arrow keys. This value also

corresponds to the vacuum reading inside

the chamber. It is recommended to use

Pulse Vent when gas flushing to a low %

vacuum. The range is 98% to 30%.

Press the MENU Key.

If the machine is equipped with the

PRECUT option, it can be turned ON or

OFF by pressing the UP or DOWN arrow

keys.

Press the MENU Key.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.5

OPERATION

Selecting a New Program

Figure 3.6

ENTER PROGAM: 2

RUNNING PROG: 1

+

-

PROGRAM

YES

NO

+

-

PROGRAM

YES

NO

From the Main Menu, use the UP and

DOWN arrow keys to select a new

program.

Press the UP arrow to switch to Program 2

(or any of the 10 programs).

New parameters may be set for Vacuum,

Seal Time, and Gas for Program 2

(following the procedures described in the

previous example) or simply close the lid

on the machine and run Program 2.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.6

OPERATION

Operation with Touch Screen

The touch screen control panel allows the user more options than the digital control panel.

The embedded microprocessor controls each sequence of the packaging operation. Settings

for the vacuum, gas, and sealing are entered as parameters through the keypad. This

allows the user to custom program every step of the packaging process. The precise vacuum

and gas pressures are controlled by a pressure based sensor. The vacuum pressure, gas

pressure, and seal time are displayed on a large 4.3” LCD touch screen, which can be read

easily in all lighting conditions. As each sequence is performed, the real-time pressure level

or cycle time is displayed.

The touch screen panel can save up to 99 pre-programmed routines, which can be retrieved

at any time for specific packaging applications. [With the supervisor security feature turned

on, these programs cannot be inadvertently changed.]

The VACPLUS option allows the operator to run the pump from .1 to 6 seconds after the set

vacuum level is achieved.

The Gas Flush option allows the operator to introduce an inert gas into the chamber after

the vacuum stage. This option can be used as a filler to prevent crushing of the product

after sealing, as a means to prolong shelf life or as a means to maintain desirable product

appearance.

The touch screen panel has an auto stop, which will automatically seal if the preset vacuum

is not reached. This feature decreases the cycle time and optimizes the vacuum level of each

product.

The touch screen panel meets or exceeds the requirements of NEMA 4. The front of the

touch screen is sealed and flush mounted for easy cleaning.

The touch screen has both pulsed vacuum and pulsed venting options for fragile product.

The touch screen has a maintenance screen for testing valves and a special loop option for

multiple vacuum/gas cycles before sealing.

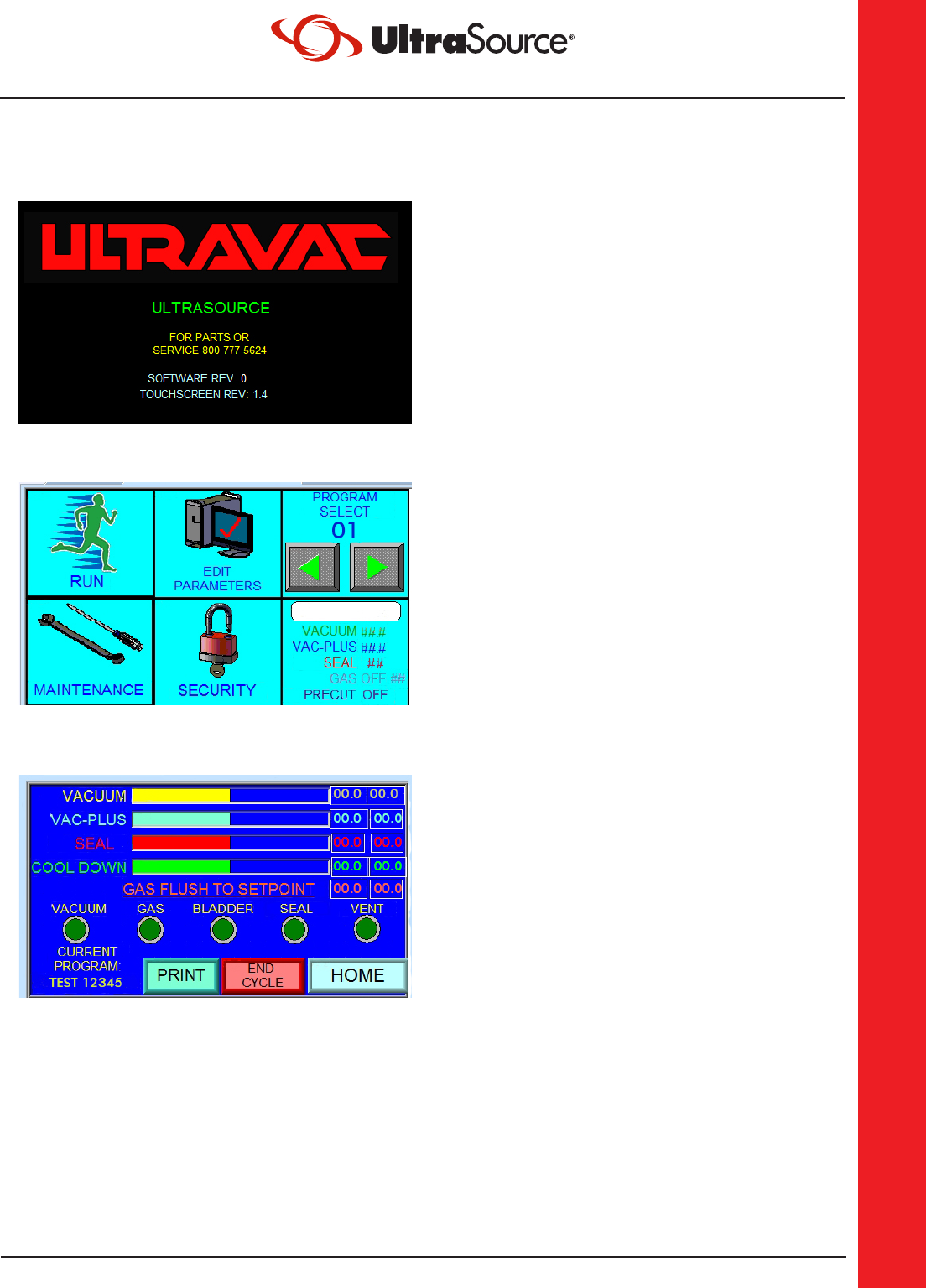

Figure 3.4

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.7

OPERATION

Operation with Touch Screen (continued)

NOTE: If the supervisor has set security on, program settings cannot be changed.

This is the splash screen. When the machine

starts up, this screen will display for a period

of time during bootup. Once the bootup

sequence has been completed, the screen

will automatically change to the Main Menu.

This is the Main Menu. This screen allows

access to all of the other functions of the

machine. A program can be selected

from this menu, and run from this menu.

Maintenance, Security, and Program

Parameters can also be edited from this

menu if the correct level of access is used.

This is the RUN Screen. This screen shows

the status of the program that is currently

being run, as well as the name of that

program.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.8

OPERATION

Operation with Touch Screen (continued)

NOTE: If the supervisor has set security on, program settings cannot be changed.

Some options may not apply to every machine.

This is the Edit Parameters screen. Every

program consists of multiple parameters.

These parameters are defined on the Edit

Parameters screen for each saved program.

VACUUM PERCENT:

This defines the percentage of vacuum to

achieve prior to sealing. The range is up to

99%.

VAC-PLUS:

This may be set from 0.1 to 6 seconds. A

setting greater than 0 allows the pump

to continue evacuating the chamber (for

the specified number of seconds) after the

pressure in the chamber has reached the %

vacuum set in the vacuum menu.

SEAL TIME:

The seal time setting is in seconds. The

range is 0 to 3 seconds.

PULSE VAC:

Pulse Vac allows for a more controlled

vacuuming process. Rather than simply

opening the vacuum valve for a continuous

vacuum, the valve is opened and closed

repeatedly until the chamber reaches the set

“Pulse Vac” vacuum level as defined in the

“Maintenance” screen.

PULSE VENT:

Pulse Vent allows for a more controlled

venting process. Rather than simply opening

up the valve for a continuous vent the

valve is opened and closed repeatedly

until the chamber vents back to the “Pulse

Vent” pressure setting as defined in the

“Maintenance” screen.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.9

OPERATION

Operation with Touch Screen (continued)

NOTE: If the supervisor has set security on, program settings cannot be changed.

Some options may not apply to every machine.

GAS OFF:

The Gas state button tells whether Gas

Flushing is turned on or off. Enable Gas by

turning this button to the ON position.

GAS %:

Gas is set to % gas by pressing the value

button on the touch screen and directly

editing the value using the provided

keypad. This value also corresponds to the

vacuum reading inside the chamber. It is

recommended to use pulse vent when gas

flushing to a low % vacuum. The range is

0.1% to 99%.

PRECUT OFF:

If equipped, This activates or deactivates the

Precut knife option

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.10

OPERATION

Operation with Touch Screen (continued)

NOTE: If the supervisor has set security on, program settings cannot be changed.

Some options may not apply to every machine.

Program selection:

The Program Select feature has 99 different

user definable presets. To set a program

number, use the left and right arrows, or

press on the program select number to

bring up a keypad for number selection..

Once the program number you desire has

been selected, press on the White box to

pull up the keyboard screen, enter a name

for your program (up to 10 characters) and

press enter. You will be returned to the main

menu.

Press Edit Parameters. From the Edit

Parameters screen, enter the desired

settings for your product requirements.

When finished, press Exit. Your parameters

are now saved to the program number you

selected.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.11

OPERATION

Sealing with Air-Assist

All machines are equipped with regulators for air-assisted sealing. Set the air pressure

regulator to 20 p.s.i. increasing to a maximum of 40 p.s.i. While a good seal can be

obtained without air-assist, use air-assist when:

• Gas back-flushing above average pressure.

• Using shrink pouches.

• Packaging a product that easily contaminates the seal area of the pouch.

• Trying to overlap pouches.

• Wrinkles cannot be avoided in the seal area.

• Using the Double Seam Seal option.

• Always use air-assist when using the Perforating Knife Option.

• Always use air-assist when using the Precut Option.

• Always use air-assist when using the 10mm Wide Seal Band Option

Gas Flush Option

Gas flushing is the introduction of an inert gas into the chamber after the vacuum stage

is finished. Gas can be used as a filler to prevent crushing of the product after sealing, as

a means to prolong shelf life, or as a means to maintain desirable product appearance.

Commonly used gasses include nitrogen, carbon dioxide, or a mixture of both. Consult your

local gas supplier to select the proper gas for your product.

WARNINGWARNING

Explosion hazard.

Do not use a gas with an oxygen content greater than 22% with gas flush option.

Double Seam Seal Option

All machines are equipped with standard seal bars having a single seal element per

seal bar. The Double Seam seal bars have two seal elements per seal bar. We strongly

recommend using air-assisted sealing with this option to achieve best results.

10mm Wide Seam Seal Option

All machines are equipped with standard seal bars having a single seal element per

seal bar. The 10mm Wide Seam seal bars have a wide seal element. It is required to use

air-assisted sealing with this option to achieve best results.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

3.12

OPERATION

Perforating Knife Option

Perforating knives are used to facilitate the removal of excess pouch material. Perforating

knives are not intended to cut pouches off completely, only to perforate so that excess

material can be easily removed by hand.

Precut Option

The precut option is a patented system designed by UltraSource to increase the versatility

of the Ultravac

®

2100. This option increases the speed in which this machine can be loaded

with product. The user simply places the pouch full of product into the machine and pulls

it close to the seal bar allowing the excess material to hang on the outside of the machine.

Not only does this increase the loading speed, but it also improves the appearance of the

final product. The precut option also allows the end user to stock fewer sizes of pouches

because excess pouch material is trimmed away.

When using this option, the bag or pouch containing product is placed inside the machine

as usual. However, rather than having to carefully tuck the bag inside the slot in the

machine before closing the lid, the open end of the bag is placed outside the machine by

simply draping the bag over the side of the machine. When the lid is closed, the seal bar is

brought down and the special precut blade cuts evacuation slits in the bag or pouch, which

allow the air inside the bag to escape during the normal evacuation process.

Start by making sure the Precut menu is set to the “ON” position. With precut, air-assisted

sealing is required. Place the bag containing product inside the chamber. Drape the open

end of the bag over the side of the machine and close the lid. When the evacuation process

is finished, the bag will have “slits” pierced in it by the precut knife. The slits allow the air to

be evacuated from the bag. The slits also facilitate the removal of excess bag material after

the completion of the cycle.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.1

MAINTENANCE

MAINTENANCE

Prior to Cleaning

Every environment and application is different; therefore, UltraSource LLC cannot provide

cleaning instructions to guarantee microbiological sanitation. UltraSource requests that the

owner of this machine consult with sanitation experts to review the unit working in their

particular environment to develop a robust cleaning schedule and methodology, followed by

bacterial testing to ensure satisfactory cleaning procedures are followed.

Cleaning Recommendations

Before cleaning the machine, turn power off; disconnect the main power, and lockout the

connection.

DANGER

Hazardous voltage.

Disconnect and lockout power before servicing machine or cleaning. Do not remove panels

unless power has been disconnected and locked out at risk of electric shock hazard.

Check with the detergent and sanitizer manufacturers that their products are compatible

with the listed materials.

CAUTIONCAUTION

Cleaning agents.

Do not get the cleaning agents in eyes, on skin, or on clothing. Always wear rubber gloves,

goggles, and protective clothing when contact is likely. Consult product manufacturer for

specific details.

Never hose down the machine. Damage caused by hosing or high pressure washing is not

covered under warranty.

1. Filler Plates: Remove filler plates. The filler plates are made from polyethylene. Clean,

sanitize, and dry. High pressure water spray can be used on the filler plates.

2. Lid, Chamber, and Base: These components are made of aluminum. Clean the lid,

chamber, base, and silicone seal backup strip with a non-ionic cleaning solution such

as Crystal Simple Green.

3. Seal Bars: Remove the seal bars. The seal bars are made of phenolic. Clean, sanitize,

and dry. Also clean under the seal bar bladder in the lid, which is not removable.

4. Clean under the machine.

5. Reinstall the seal bars.

6. Use bacteriological testing to insure cleaning process.

WARNINGWARNING

Electrical Supply Cord.

The supply cord must be replaced by an Ultravac Services Service Technician or similarly

qualified person in order to avoid hazard.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.2

MAINTENANCE

Step 1.

Remove the seal bars from the machine. Pull

off the Teflon

®

tape strip and discard. Clean

off any remaining Teflon

®

tape adhesive

using acetone or an equivalent solvent.

Step 2.

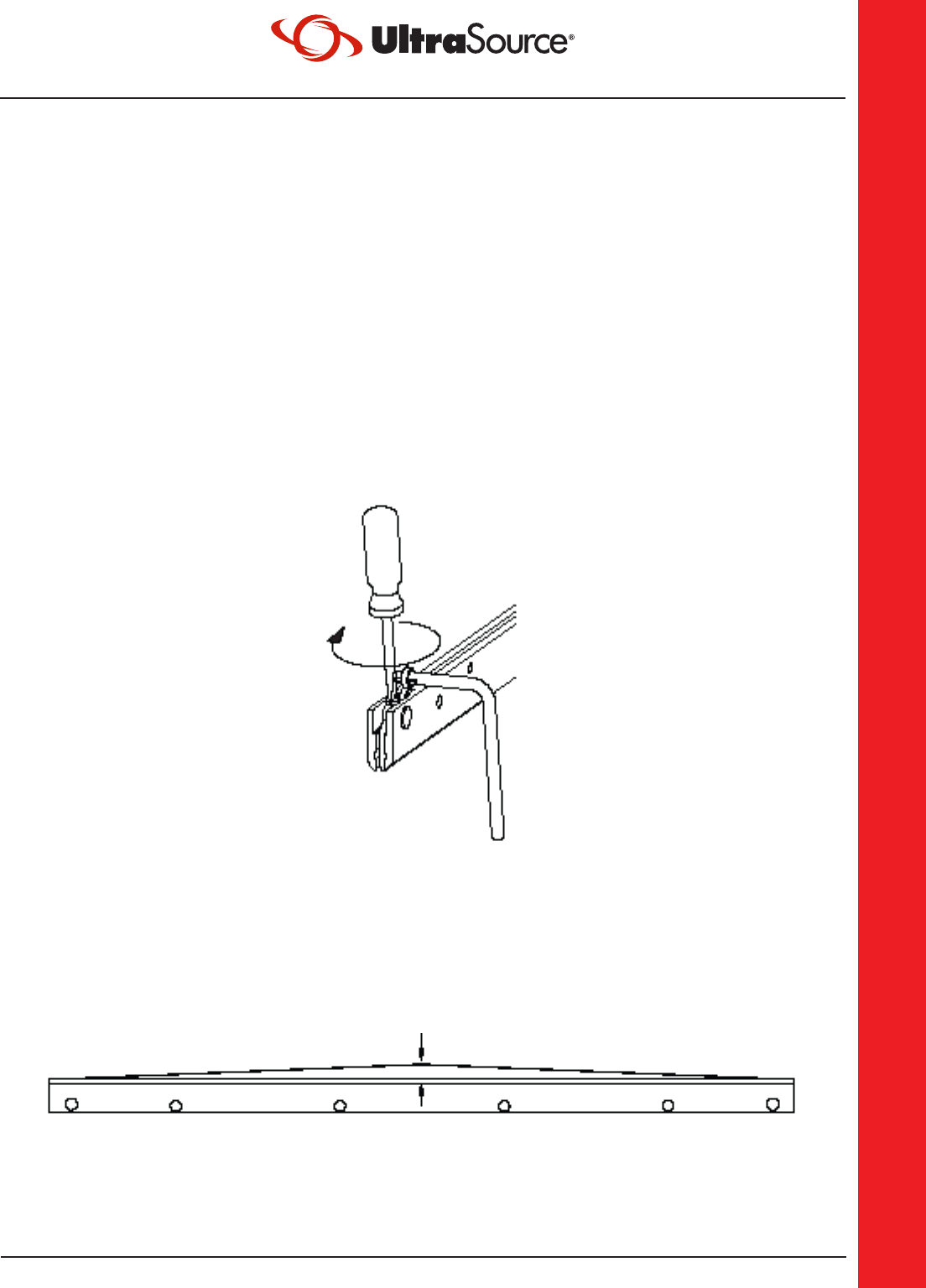

Using a 2mm Allen wrench, loosen the set

screws for the cut-off wire and the seal

element on both ends of the seal bar and

discard.

Step 3.

If you are replacing the L-shaped spring retainer and the spring at this time, loosen the set

screw and remove the old spring retainer and spring and install the new ones. Adjust the

spring retainer to allow a 1/8-in. gap between the spring retainer and the seal bar. This will

allow the seal element to remain under tension after tightening the seal element.

Vacuum Pump Maintenance

Consult the pump manufacturer’s manual provided with the machine for detailed

information.

Seal Bar Maintenance

The following illustrations show replacement of the seal elements for the seal bars.

Figure 4.1

Figure 4.2

Figure 4.3

Teflon

®

tape

Clamping

Screw

Spring

Retainer

Brass

Contact

Tightening

Tool

Seal

Element

Spring

Retainer

1/8-in.

Set

Screw

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.3

MAINTENANCE

Seal Bar Maintenance (continued)

Step 4.

Insert the new seal element through the hole in the brass contact. Leave about 3/4-in.

of excess seal element extending past the brass contact and tighten the clamping screw.

Insert the other end of the element through brass contact on the opposite end of the seal

bar. Place a slotted tip screwdriver on top of the seal element and against the brass contact

where the seal element exits. Using the tightening tool provided (or needle nose pliers),

tighten the seal element as shown.

Step 5.

While maintaining tension on the tightening tool, use the slotted tip screwdriver to tighten

the clamping screw.

NOTE: A 1.5mm Allen wrench will be needed to tighten the clamping screws on a Double

Seam seal bar.

Step 6.

Check the tension of the seal element by pulling it up at the middle of the bar. The seal

element should not pull beyond 3/16-in. of the seal bar. If there is not enough tension,

tighten as necessary. Elements may break in the middle of the bar if tension is not set

properly. Install the new Teflon

®

tape strip over the bar.

3/16-in. maximum

Figure 4.4

Figure 4.5

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.4

MAINTENANCE

Reading the Indicators

All machines are controlled by an analog control module (with knobs) or a digital control

module (with touch pad) designed to aid in troubleshooting. The analog control module,

mounted behind the front control panel, has five red indicator lights (LEDs) mounted to it.

To view the indicator lights on the analog control module during operation remove the six

screws on the front of the control panel and pull the control panel out. The digital panel

has indicator lights mounted on the front below the ON/OFF switch. The indicator lights

correspond to the operating devices and should turn on and off in the following sequence

when the machine lid is closed:

1. Vacuum Valve [SOL-1]

2. Gas Flush Valve [SOL-2] (Optional)

3. Seal Bladder Valve [SOL-3]

(Stays on until completion of cycle)

4. Seal Impulse Contractor [C-2]

5. Ventilation Valve [SOL-4]

The device should be operating when the LED is illuminated. If the LEDs illuminate in the

proper sequence, but there is still a problem, look for the problem in the operating device

itself. If the LEDs do not sequence properly, look for a problem in the related potentiometer

or the control module.

1. VACUUM VALVE [SOL-1]

2. GAS FLUSH VALVE [SOL-2] (OPTIONAL)

3. SEAL BLADDER VALVE [SOL-3]

(STAYS ON UNTIL COMPLETION OF CYCLE)

4. SEAL IMPULSE CONTACTOR [C-2]

5. VANTILATION VALVE [SOL-4]

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.5

MAINTENANCE

Troubleshooting

Problem Indications Remedy

Machine will not start Green power “ON” light not

lit when switch is turned on

Make sure that the power

requirements match those given

on the nameplate. Also, check

fuse F-3; replace if blown.

Vacuum pump does not run Make sure that the power

requirements match those given

on the nameplate. Also, check the

overload OL-1; reset if necessary.

No vacuum When lid is closed, indicator

light (VAC) is “OFF” on the

control module

Check lid switches LS-1 and LS-2

for proper adjustment

Vacuum not pulling lid down

on both sides

Check intake screen in vacuum

pump hose barb for blockage,

pieces of bags, labels, bone, etc.

Longer vacuum cycle times Check intake screen in vacuum

pump hose barb for blockage

No gas flush (optional) If indicator light (GAS) is lit Check for proper gas pressure

going into gas inlet

If indicator light (GAS) is not

lit

Check for proper operation of gas

flush valve (SOL-2)

possible defective control module

Gas flushes to one chamber

side only

Check gas flush selector valve

(V-1) for proper adjust

Chamber not venting

(lid will not open)

Lid will not open and red

indicator light “VENT” on

control module is lit

Check ventilation valve SOL-4 for

proper operation

“VENT” indicator light is not

lit

possible defective control module

NOTE: Lid can be released by pulling the hose off of

the vacuum gauge to remove product.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.6

MAINTENANCE

Troubleshooting

Problem Indications Remedy

Improper or no

sealing

Bladder light on control

module is lit but the seal bar

does not come down

Check to make sure that the

regulator knob is turned fully

clockwise, or, if air-assist is used,

set to the recommended pressure

Check seal bladder valve SOL-3

for proper operation

The seal bar is not heating

up even though the red

seal light on the front panel

comes on

Check seal bar connection points

and clips for corrosion and proper

tension

The red seal light on the

front panel either does not

light for the proper length

of time (1/2 to 1 second) or

does not light at all

Check for broken seal element

Check seal bar fuse F-1 for front

seal bar and F-2 for rear seal bar*

Make sure the seal impulse

potentiometer POT-3 is set high

enough or check for defective

control module

Front or rear seal bar

heating, but not both

Check seal bar fuse F-1 for front

seal bar and F-2 for rear seal bar*

* Fuses F-1 and F-2 only apply to machines shipped before 1/1/2006.

NOTE: For proper sealing, three things must occur:

1. The seal bar must come down and place adequate pressure between the seal bar and

the backup strip.

2. The seal element must heat up sufficiently to fuse the pouch.

3. The pouch must be allowed to cool for a time to ensure a good “set.”

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.7

MAINTENANCE

Supervisor Menu on Digital Panel

Untrained personnel should not alter any setting in the supervisor menu.

Figure 4.6

WAITTIME: 4

CUTTIME: 1.5

PREVAC: 25

RUNNING PROG: 1

NO

YES

PROGRAM

NO

YES

PROGRAM

NO

YES

PROGRAM

NO

YES

PROGRAM

-

+

-

+

-

+

-

+

This is the main menu screen. When

the machine starts up, the last program

that was run will be the current program

shown in the window.

Press and hold down both arrow keys for

at least 3 seconds to enter the supervisor

menu.

NOTE: If your machine is not installed

with the precut option, disregard the

PREVAC, CUTTIME, and WAITTIME

parameters.

PREVAC is the % vacuum that you wish to

reach before activating the knife, which

makes slits in the bag for precut. Use the

up or down arrow keys to change the

current setting.

The range is from 5% to 20% vacuum.

Press the MENU key.

CUTTIME is the number of seconds that

the seal valve is activated. This is the

time when the knife actually makes the

evacuation slits in the bag/pouch for

precut. The range is from 0 to 3 seconds.

Press the MENU key.

WAITTIME is the number of seconds the

machine waits for the knife to retract

before resuming the vacuum cycle. The

range is from 0 to 6 seconds.

Press the MENU key.

The following are parameters that can

only be set in the supervisor menu.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.8

MAINTENANCE

Supervisor Menu on Digital Panel

Figure 4.7

# PROGRAMS: 10

SECURITY: NO

COOLDOWN: 4.0

TEST: YES

NO

YES

PROGRAM

NO

YES

PROGRAM

NO

YES

PROGRAM

NO

YES

PROGRAM

-

+

-

+

-

+

-

+

COOLDOWN is the time that the machine

waits after sealing the bag/pouch before

the seal bars retract. This allows time for

the actual seal to cool down and take a set.

The range is from 1 to 8 seconds.

Press the MENU key.

SECURITY can be turned on by selecting

yes. If security is on, the operator menu will

be read only and the operator will not be

able to change any settings.

Press the MENU key.

This is how you specify the maximum

number of programs that may be saved in

memory. Each program may have its own

set of unique parameters.

This range is from 1 to 10.

Press the MENU key.

If TEST is set to YES (using the up arrow

key), the vacuum valve and vent valve may

be operated manually. The up arrow key

activates the vacuum valve, the down arrow

key activates the vent valve, and pressing

both at the same time turns them both off.

As you activate either valve, the vacuum

pressure is displayed.

Press the MENU key.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.9

MAINTENANCE

Supervisor Menu on Digital Panel

PULSE OFF: 1.0

PULSE ON: 1.2

PULSE TO: 50

PULSE VENT: YES

NO

YES

PROGRAM

NO

YES

PROGRAM

NO

YES

PROGRAM

NO

YES

PROGRAM

-

+

-

+

-

+

-

+

PULSE VAC allows for a more controlled

vacuum process. Rather than simply

opening up the vacuum valve for a

continuous vacuum, the vacuum valve is

opened and closed repeatedly until the

chamber reaches the desired vacuum.

Press the MENU Key.

This is the % vacuum reached by pulsing

the vac valve.

The range is 90% to 30%.

Press the MENU Key.

This is how long the vacuum valve is

turned on during the vacuum cycle.

The range is 0 to 3 seconds.

Press the MENU Key.

This is how long the vacuum valve is

turned off during the vacuum cycle.

The range is 0 to 3 seconds.

Press the MENU Key.

Figure 4.9

PULSE VAC

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.10

MAINTENANCE

Supervisor Menu on Digital Panel

Figure 4.8

PULSE OFF: 1.0

PULSE ON: 1.2

PULSE TO: 50

PULSE VENT: YES

NO

YES

PROGRAM

NO

YES

PROGRAM

NO

YES

PROGRAM

NO

YES

PROGRAM

-

+

-

+

-

+

-

+

PULSE VENT allows for a more controlled

venting process. Rather than simply

opening up the vent valve for a continuous

vent, the vent valve is opened and closed

repeatedly until the chamber vents back to

atmospheric pressure.

Press the MENU Key.

This is the % vacuum reached by pulsing

the vent valve before the vent valve opens

completely to fully vent the chamber.

The range is 90% to 30%.

Press the MENU Key.

This is how long the vent valve is turned on

during the vent cycle.

The range is 0 to 3 seconds.

Press the MENU Key.

This is how long the vent valve is turned

off during the vent cycle.

The range is 0 to 3 seconds.

Press the MENU Key.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.11

MAINTENANCE

EXIT GAS: YES

LOOP #: 1

NO

YES

PROGRAM

NO

YES

PROGRAM

-

+

-

+

VAC TIMEOUT: ON

NO

YES

PROGRAM

-

+

If the machine is equipped with the LOOP

option, this is the number of vacuum/gas

cycles the control will perform prior to the

seal and vent.

The range is 1 to 5 cycles.

The default value is 1 cycle.

Press the MENU Key.

If the Loop # is set greater than 1, the

control can be set to exit this loop on either

the last gas cycle or the last vacuum cycle

prior to sealing.

The DOWN arrow key indicates NO.

The UP arrow key indicates YES.

Press the MENU Key.

VAC TIMEOUT is an option that is turned

ON or OFF. If set OFF, default, the machine

will time out if the preset vacuum is not

reached in 6 seconds, and the machine

will complete the cycle. If set ON and the

machine does not reach the preset vacuum

in thirty seconds, then the panel will display

VAC ERROR and vent the chamber without

sealing.

Supervisor Menu on Digital Panel

Figure 4.10

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.12

MAINTENANCE

Supervisor Menu with Touch Screen

NOTE: If the supervisor has set security on, program settings cannot be changed.

This is the Main Menu. This screen allows

access to all of the other functions of

the machine. The supervisory menu can

be accessed by entering the required

maintenance password in Security, and then

pressing the Maintenance button.

Default Maintenance Password is listed in

the security setup section of this manual.

This is the primary Maintenance menu.

This allows access to all of the various

supervisory and maintenance related

screens.

Global Parameters consist of machine

specific global parameters such as Vacuum

Time Out limits, Cool Down times, and

Language Selection.

Security Setup allows the default passwords

to be changed, and allows the supervisor to

restrict the editing of program parameters

to Maintenance level supervisors or to allow

anyone using the machine to make these

changes.

Pulse Vac-Vent Setup allows the supervisor

to configure the behavior of the Pulse Vac

and Pulse Vent operations if being used.

Configuration is a factory configuration

menu that allows the touch screen to

be properly configured for operation on

a specifically equipped machine. These

settings should NEVER be changed in

the field unless instructed to do so by an

Ultravac Services technician.

Precut Options: If the machine is equipped

with the PRECUT option, selecting this icon

allows the parameters to be set. See precut

and looping options for details

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.13

MAINTENANCE

Supervisor Menu with Touch Screen (continued)

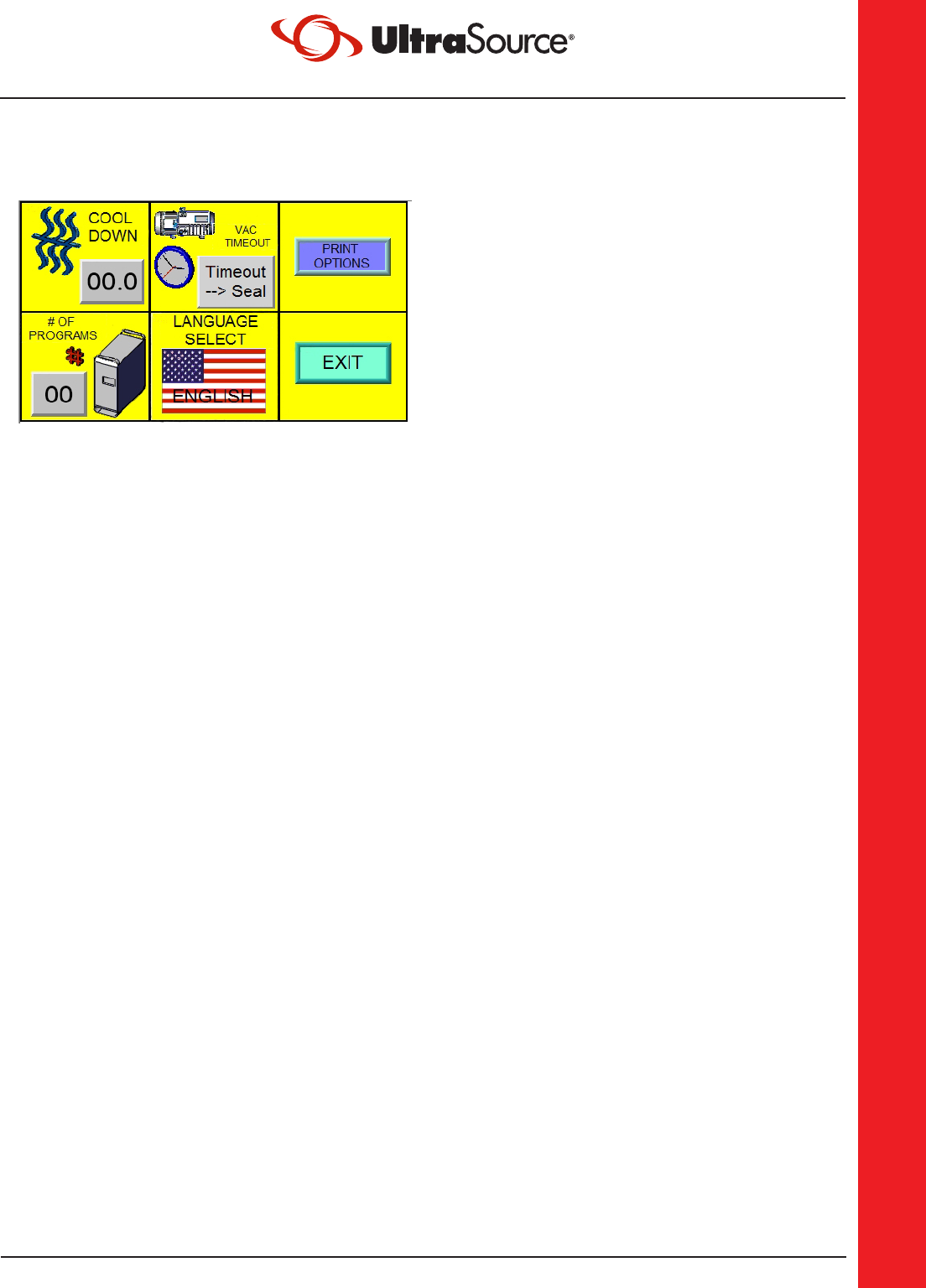

Global Parameters

Cool Down: This parameter determines how

long the cool down period is in each cycle.

This can be set by pressing the value button

and changing the value using the provided

keypad. The range for this value is 0 to 10.

Vac Timeout: The Vacuum Timeout

parameter determines how the machine

behaves if the Vacuum Timeout is reached

before the cycle completes.

Timeout --> Seal: This will cause the

machine to seal the package

immediately if a Vacuum Timeout

fault occurs.

Timeout --> Vent: This will cause the

machine to stop the vacuum process,

vent the chamber and leave the

package unsealed.

Print Options: This is used to enable/disable

the printer function.

# of Programs: This parameter defines the

number of programs that can be stored. The

range for this value is 1 to 99.

Language Select: This allows the user to

select a different operating language for

the touch screen. The machine is equipped

with four base languages including English,

French, German and Spanish. The language

can be selected simply by pressing the flag

like button and cycling through the options.

Press Exit when done and this will save your

changes.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.14

MAINTENANCE

Following the selection of Print Options in

Global parameters, this screen will appear.

Enabling or disabling the printer feature is

done by selecting the Print ON/OFF but-

ton.

The Company name field contains up to

12 characters. This field may be used for

any text, such as Lot Number, for any given

product run. Enter desired text, press and

hold Save name until you hear two beeps..

The default time is set to CST (GMT-6:00).

You will need a pencil eraser to perform

this operation. Press the arrow key in the

lower RH corner and the Icon group will

appear to the left. Press the Gear Icon and

the virtual keypad will appear. Press the

number 1 six times, and press enter. The

System settings screen will appear, and

you will be in the network settings tab,

which does not apply to these machines.

Please note the time is formatted as a 24

hour clock!!! Select the Time/Date tab at

the top of the system settings screen, and

using your eraser adjust the time and date.

When finished, press apply, and press OK.

The time and date have now been saved.

The remaining tabs SHOULD NOT be

used! Changes to these features should

only be performed or under direction of a

trained Ultravac Services technician!!

Supervisor Menu with Touch Screen (continued)

Print Options

111111

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.15

MAINTENANCE

Supervisor Menu with Touch Screen (continued)

Security Setup

The security setup screen allows the

maintenance supervisor to enable a certain

level of security and to change the default

passwords assigned to the machine.

The default passwords are as follows:

Level One: 456

Level Two: 789

Turning Security On in this menu will

restrict the editing of program parameters

to those with a value Level One password.

The Maintenance menu will always remain

secured by the Level Two password.

If Security is set to Security Off (as shown

in the corresponding image to the left),

running program parameters will be

editable by anyone.

Changing the default passwords can be

done by setting the new password in this

screen. Keep in mind that these passwords

are NOT recoverable should they be

forgotten.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.16

MAINTENANCE

Supervisor Menu with Touch Screen (continued)

Pulse Vac and Pulse Vent Setup

Pulse Vac and Pulse Vent Setup allows the

maintenance supervisor to configure the

appropriate Pulse Vac and Vent limits.

Pulse Vac On Time:

This value determines how long each pulse

is fired during a Pulse Vac operation.

Pulse Vac Off Time:

This value determines how long each pulse

is in the off position during a Pulse Vac

operation.

Pulse Vac to Percent:

This value determines the final desired

vacuum percentage to be reached during a

Pulse Vac operation.

Pulse Vent On Time:

This value determines how long each pulse

is fired during a Pulse Vent operation.

Pulse Vent Off Time:

This value determines how long each pulse

is in the off position during a Pulse Vent

operation.

Pulse Vent to Percent:

This value determines the final desired

vacuum percentage to be reached during a

Pulse Vent operation.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.17

MAINTENANCE

Supervisor Menu with Touch Screen (continued)

Precut and Looping options

Prevac - 0-99% of vacuum before slits

are cut in the bag. Default 25%

Cut time - Amount of time allotted for

the cut cycle, 0.1 - 9 seconds Default 1.5

seconds

Wait time - Amount of time from Cut

cycle finish to Vacuum cycle startup

0.1 - 9 seconds, Default 4 seconds.

If the machine is equipped with the loop

option, this is the number of vacuum/

gas cycles the control will perform prior

to the seal and vent. The range is 1 to 5

cycles. The default is 1.

If the loop # is set to greater than 1,

the control can be set to exit the loop

on either the last gas cycle or the last

vacuum cycle prior to sealing.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.18

MAINTENANCE

Changing Vacuum Pump Oil and Filter

NOTE: The pump should have been running for at least 15 minutes to warm the pump oil.

1. Turn the power switch to the “OFF” position and disconnect the power.

DANGER

Hot oil.

Hot oil poses scalding risk. Take necessary precautions while draining warm oil.

DANGER

Hazardous voltage.

Disconnect and lockout power before servicing machine or cleaning. Do not remove panels

unless power has been disconnected and locked out at risk of electric shock hazard.

2. Position an oil collection pan underneath the Oil Drain Plug.

3. Loosen and remove the Oil Fill Plug with a 1¼-in. open end wrench.

4. Loosen the Oil Drain Plug located to the front and lower middle on the pump with a

1¼-in. open end wrench. Remove the plug slowly to control the flow of oil.

5. Replace auto-type oil filter with a filter wrench (strap wrench.) Coat face of gasket on

new filter with oil and hand tighten until gasket contacts base, then tighten two-thirds

turn more. DO NOT OVER TIGHTEN.

6. With the oil drained, replace the Oil Drain Plug and wipe any excess oil off of the pump.

7. Fill the pump with oil until the level is at the maximum lines on the Oil Sight Glass.

Replace the Oil Filler Cap.

8. Reconnect the power cord back into the wall receptacle.

9. Cycle the machine a couple of times, unplug, and check the Oil Level. Add oil to the

maximum line. DO NOT OVER FILL.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.19

MAINTENANCE

Maintenance Log

A maintenance log is a journal of all maintenance performed. Each entry includes a

date, maintenance performed (details about the type of work done), and technician (who

performed the maintenance). The maintenance log is also a place where a schedule is kept

for further maintenance.

A maintenance log will clearly show oil changes, daily inspections, Teflon

®

tape

replacement, and so on. A master copy has been provided on page 4.20, please create a

copy and store in the back of this owner’s manual.

Service Log

A service log is a journal of all service work performed. Each entry includes a date, service

provided (details about the type of service), and technician (who performed the service).

A service log will clearly show training provided, frequent wear items, and so on. A master

copy has been provided on page 4.21, please create a copy and store in the back of this

owner’s manual.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.20

MAINTENANCE

Maintenance Log

Date Maintenance Performed Technician

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.21

MAINTENANCE

Service Log

Date Service Provided Technician

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

4.22

MAINTENANCE

THIS PAGE LEFT BLANK INTENTIONALLY.

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

5.1

SCHEMATICS

SCHEMATICS

Designation and Function of Controls

The following designations are found on the Electrical Diagrams:

Manually Activated Switches and Buttons:

SW-1 On/off control power

SW-3 On/off gas flush

SW-4 Quick seal (Optional)

Limit Switches:

LS -1 Left chamber cycle start

LS-2 Right chamber cycle start

Contactors:

C-1 Vacuum pump

C-2 Seal impulse

C-3 Redundant seal impluse

Overloads and Fusing:

OL-1 Vacuum pump motor

F-3 Control power fuse

Control Modules:

MCM Master control module

R-1 Redundant seal impluse

contactor timer

Control Lights:

LT-1 On/off control power

light (green)

LT-2 Seal impulse on light

(red)

Transformers:

T-1 Seal impulse, front

T-2 Seal impulse, rear

T-3 Control power

Motors:

M-1 Vacuum pump

Solenoid Valves:

SOL-1 Vacuum flush solenoid

SOL-2 Gas flush solenoid

SOL-3 Seal bladder solenoid

SOL-4 Ventilation solenoid

Mechanically Activated Switches

(Pneumatic Diagram only):

V-1 Gas selector valve

STARTUP

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

5.2

SCHEMATICS

230 Volt, Single Phase, Digital Panel

STARTUP

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

5.3

SCHEMATICS

230 Volt, 3 Phase, Digital Panel

STARTUP

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

5.4

SCHEMATICS

380 Volt, 50 Hz, Digital Panel

STARTUP

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

5.5

SCHEMATICS

380 Volt, 50 Hz, W/O Neutral Digital Panel

STARTUP

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

5.6

SCHEMATICS

460 Volt, 3 Phase, Digital Panel

STARTUP

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

5.7

SCHEMATICS

575 Volt, 3 Phase, Digital Panel

STARTUP

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

5.8

SCHEMATICS

Pneumatic Diagram

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

6.1

PARTS

PARTS

Recommended Spare Parts

Qty.

UltraSource

Part No.

Description

1 ea 8610 01 Seal Bar Assembly

10 ft 880431 Back Up Strip

4 ea 880443 Back Up Strip Textured

12 ft 880432 Lid Gasket

1 ea 88 0746 Seal Element

3 ft 885507 Teflon

®

Tape

1 ea 860908 DIN Coil

1 ea 860906 Vacuum Valve Diaphragm

1 ea 860907 Vent Valve Diaphragm

2 gal Specify pump Vacuum Pump Oil

1 ea Specify pump Vacuum Pump Oil Filter

1 ea 861002 Bladder Assembly

Select your machine’s configuration:

1 ea 860250 Double Seam Seal Bar Contact Kit

1 ea 863016 10mm Wide Seal Bar Contact Kit

1 ea 861013 Single Seam Seal Bar Contact Kit

For Analog Control Panel:

5 ea 860337 Fuse for Control Power, 1A

1 ea 860313 Potentiometer, Evac/Gas

1 ea 860314 Potentiometer, Sealing

1 ea 860327 Relay Module

For specific system replacement parts,

Contact a parts representative for further assistance:

Phone (816) 753-2150 • Fax (816) 561-2854

Toll-Free (800) 777-5624

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

6.2

PARTS

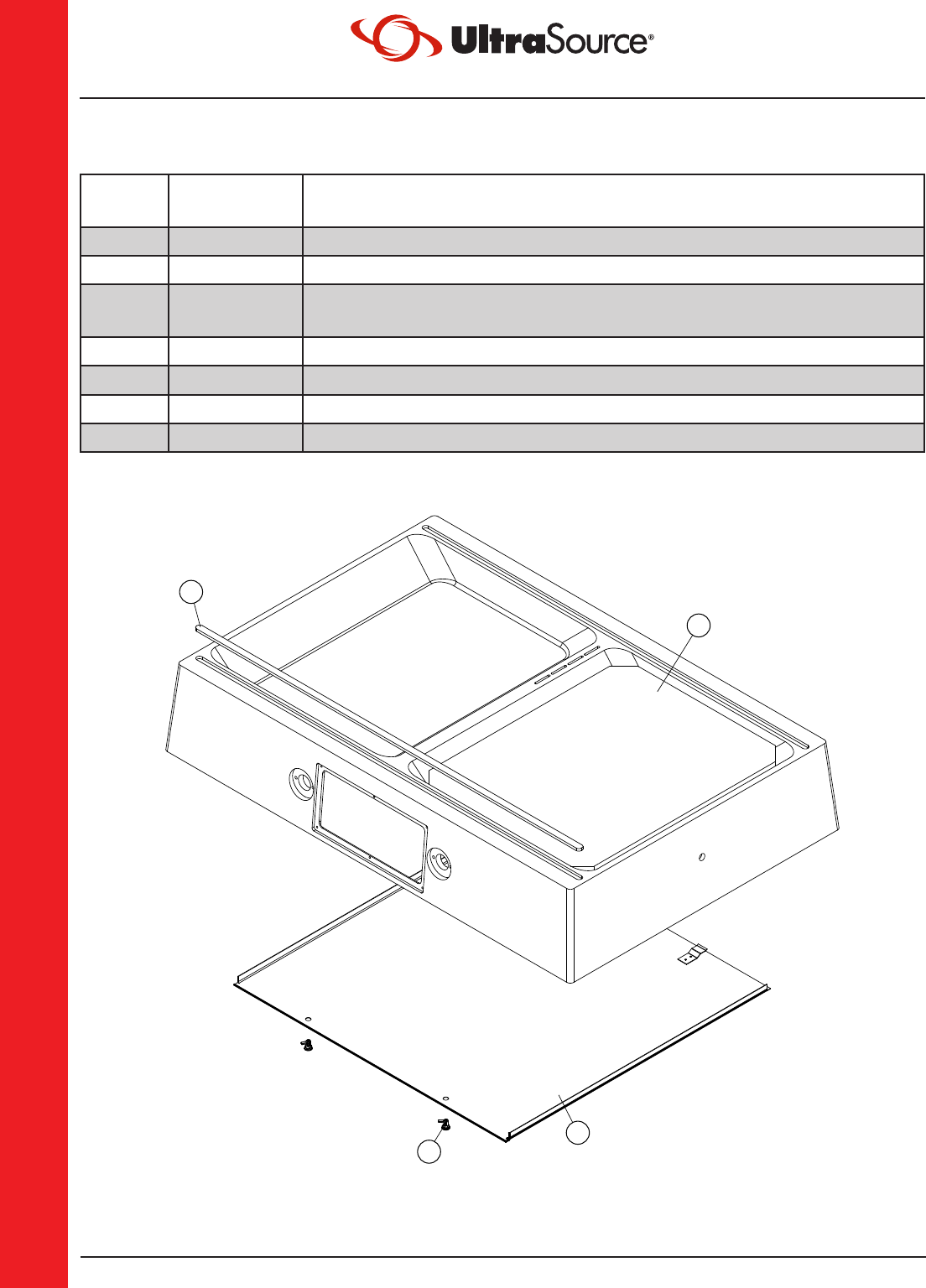

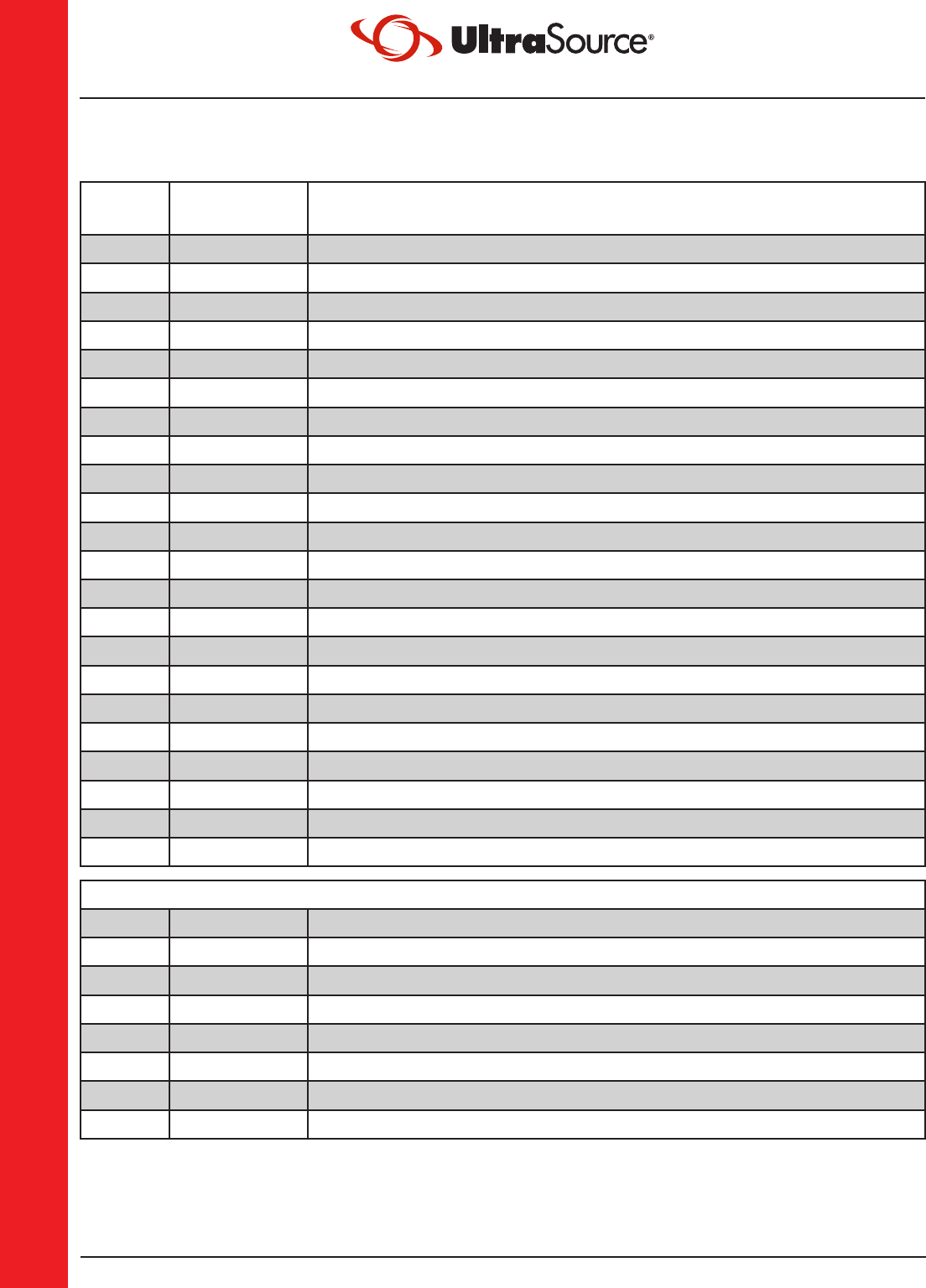

Miscellaneous Machine Parts

Parts List and Diagram

Item

No.

UltraSource

Part No.

Description

1 860402 Filler Plate Set (two sets per machine)

3 880431 Chamber Gasket (10-ft. required)

860950

Chamber Gasket, Grey (10-ft. required)

(for precut and perforating knife options)

880443 Chamber Gasket - 4 pcs. - Textured

4 860844 Cover Panel with Latches

5 860409 Latch

861228 Coiled Lanyard (between chassis and cover)

3

4

5

1

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

6.3

PARTS

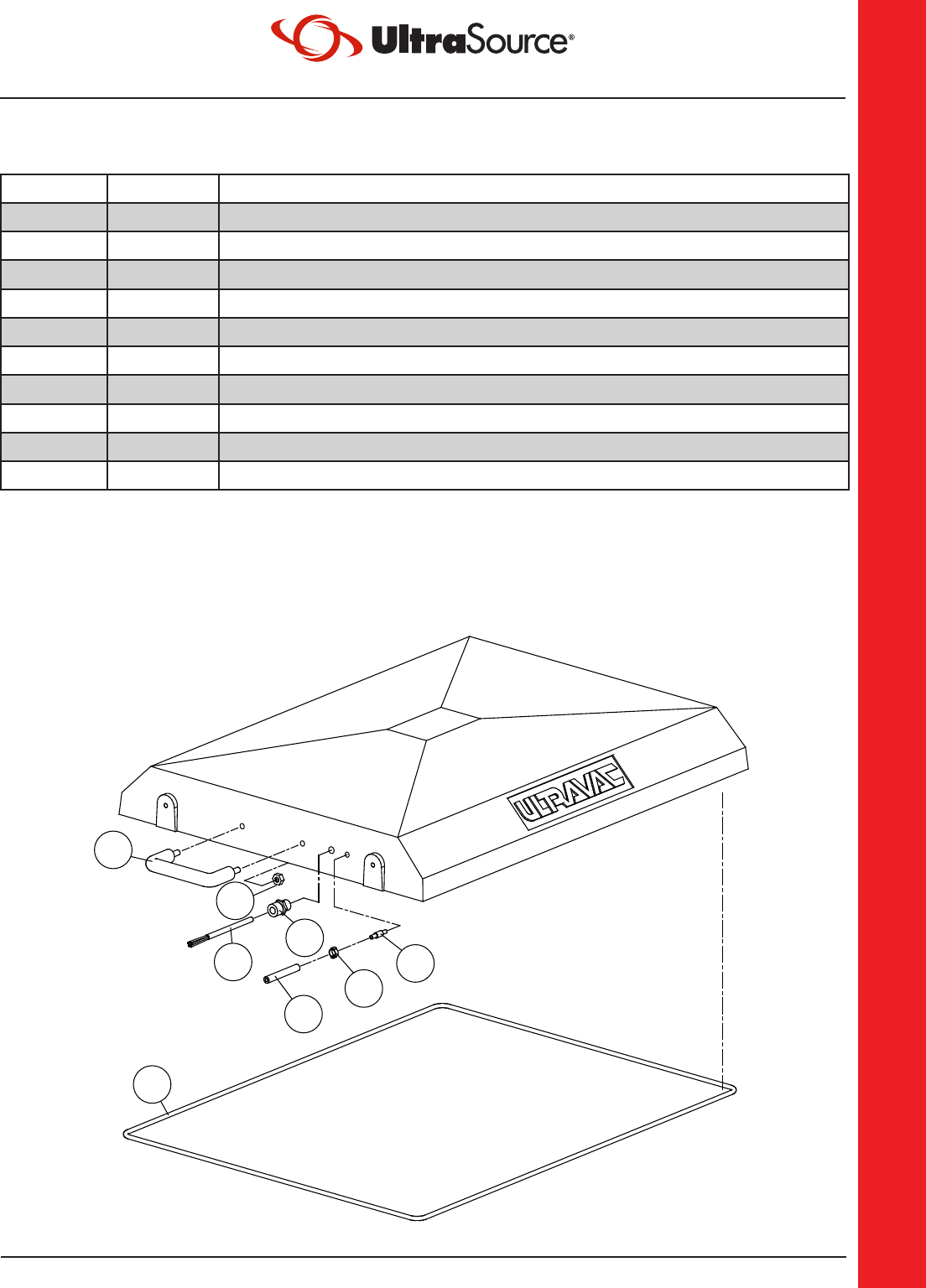

Lid, External

Parts List

Item No. Part No. Description

860200 Lid casting, 8-in. (Lid Assy available, Call our Parts Dept.)

860201 Lid casting, 12-in. (Lid Assy available, Call our Parts Dept.)

1 880432 Lid Gasket (12-ft. required)

2 860954 Hose, 1/4-in. Reinforced (35-in. required)

3 860110 Hose Clamp for 1/4-in. Reinforced Hose

4 860109 Brass Hose Barb

5 863031 Wire Harness, Complete

6 860009 Cord Grip, 1/2”NPT, .375”-.500”

7 8 6 0113 Lid Handle

8 860269 Nut, M10 Nylon Lock

1

2

3

4

6

5

8

7

THE NEW STANDARD FOR INNOVATION • [email protected] • UltraSourceUSA.com

UltraSource LLC • 1414 West 29th Street • Kansas City, MO 64108-3604 USA • 800.777.5624 • 816.753.2150

6.4

PARTS

Lid, Internal

Parts List

Item

No.

UltraSource

Part No.

Description

1 861071 10mm Wide Seal Bar Complete (refer to page 6.9)

903037-10 10mm Wide Seal Bar with Knife (one complete assembly)

861001 Single Seam Seal Bar Complete (refer to page 6.11)

860001 Single Seam Seal Bar with Knife (one complete assembly)

2 860102 Seal Bar Support

3 860226 Seal Bar Support Washer

4 860254 Screw, M5x25 Slotted Flat Head

5 860261 Nut, 5mm Nylon Lock

6 860258 Screw, M5x8 SHCS

7 860257 Screw, M5x20 Slotted Pan Head

8 860005 Electrical Contact

9 866832 Screw, M5x35 SHCS

10 860260 Washer, 5mm Lock

11 866764 Nut, 5mm Hex

12 860954 1/4-in. Hose (specify length)

13 860107 1/4-in. Hose “T”

14 860110 Hose Clamp

15 860307 Bladder Return Spring